AMERICAN SPECIALTIES, INC.

441 Saw Mill River Road, Yonkers, NY 10701

(914) 476.9000 • (914) 476.0688

www.americanspecialties.com

THIS MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES IN DESIGN OR DIMENSIONS WITHOUT FORMAL NOTICE

AUTOMATIC FOAM SOAP DISPENSER

MODEL №: 20365

ISSUED: 06/10

REVISED: 3 NOV 2016

SPECIFICATION

Automatic Foam Soap Dispenser shall hold 33.8 oz (1000 ml) of liquid foaming soaps within the viscosity range of 5-1500

cP (MPa∙s) and pH range of 5-9 and dispense in cycles of single shot foam volume ranging from 1/2 oz to 1/3 oz (7 cm³ to 9

cm³) using 0.02 oz~0.03 oz (0.6~0.77 ml) liquid for each shot. Operation is initiated by hands-free sensor controlled by

microprocessor digital circuitry powered by four (4) AA size 1.5V batteries (supplied by others) in a concealed compartment

and locked inside unit bottom. Unit shall be fabricated of 22 gauge (.031" [0.8] thick) type 304 stainless steel alloy 18-8 with

a uniform satin finish over all exposed surfaces. Cover shall have lock keyed alike with other ASI washroom accessories.

Unit shall have an LED to indicate function and operational condition on front face. Internal tank shall be translucent to

show quantity of soap remaining at any time when cover is opened and shall be easily removed to facilitate filling and

external storage of full tanks. Unit shall mount to wall on concealed base plate with screws secured under locked cover.

Mounting template and Owner’s Manual shall be provided with unit in each carton.

Automatic Foam Soap Dispenser shall be Model № 20365 of American Specialties, Inc., 441 Saw Mill River Road,

Yonkers, NY 10701-4913

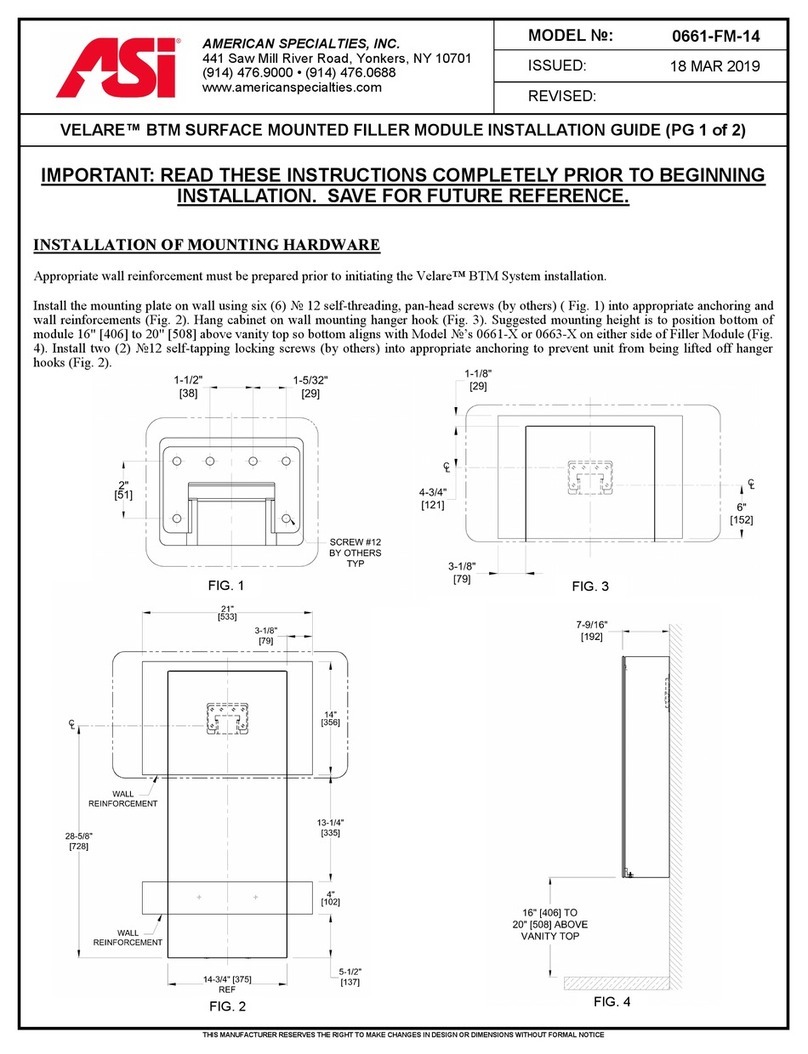

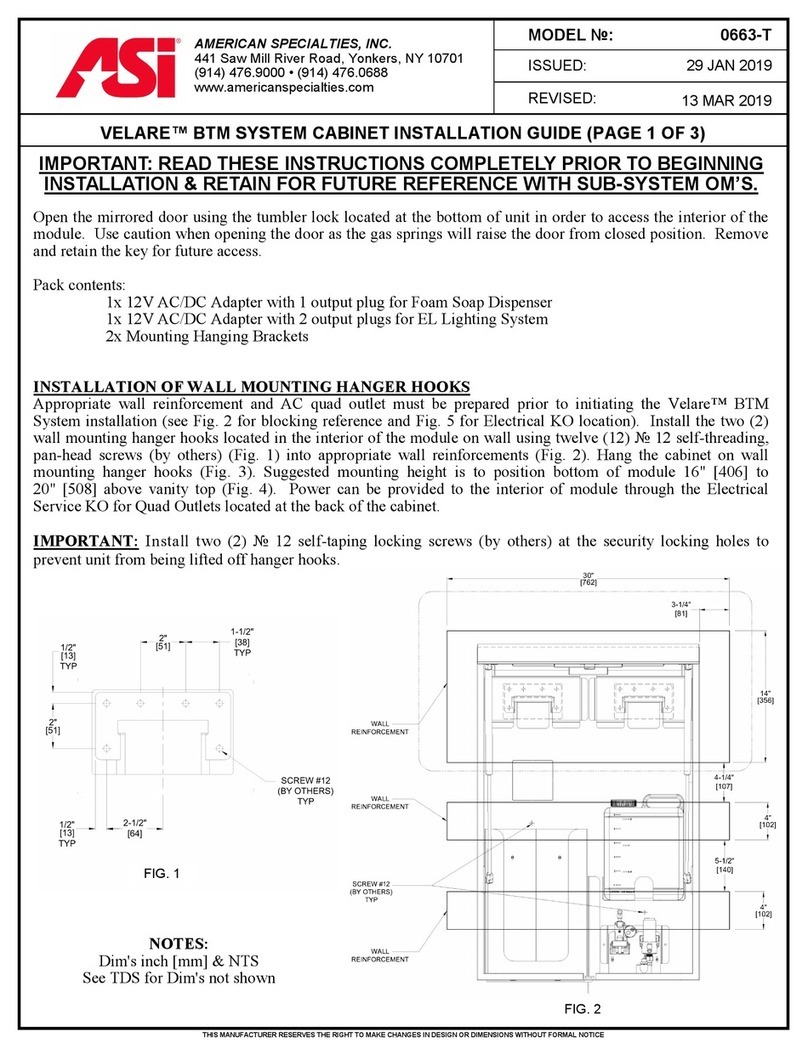

INSTALLATION

Secure concealed base plate to wall with four (4) self-tapping screws (not supplied: two (2) № 8 x 3/4" [M4.5 x 20] pan head

& two (2) № 8 x 3/4" [M4.5 x 20] flat head) through mounting holes provided in plate into plastic wall anchors (supplied by

others) or other suitable mounting system (provided by others). Install four (4) AA size 1.5V cells (supplied by others) in

concealed battery compartment according to polarity indication and snap-latch battery door. Fill tank with appropriate

viscosity soap to correct level and lock door. Locking door activates concealed button to initiate operation. Retain key

provided for future access.

OPERATION

Unit shall operate each time an object is positioned within the sensing distance of 3-1/8" ± 3/8" [80 ± 10] from unit bottom.

A foam drop of 1/2 oz to 1/3 oz (7 cm³ to 9 cm³) will be pumped out of the nozzle on unit bottom for each activation while

batteries are at suitable charge level (LED is not flashing) and correct viscosity liquid soap is present in the tank. Door has

lock to provide security and vandal resistance after each soap refill and battery change service interval.