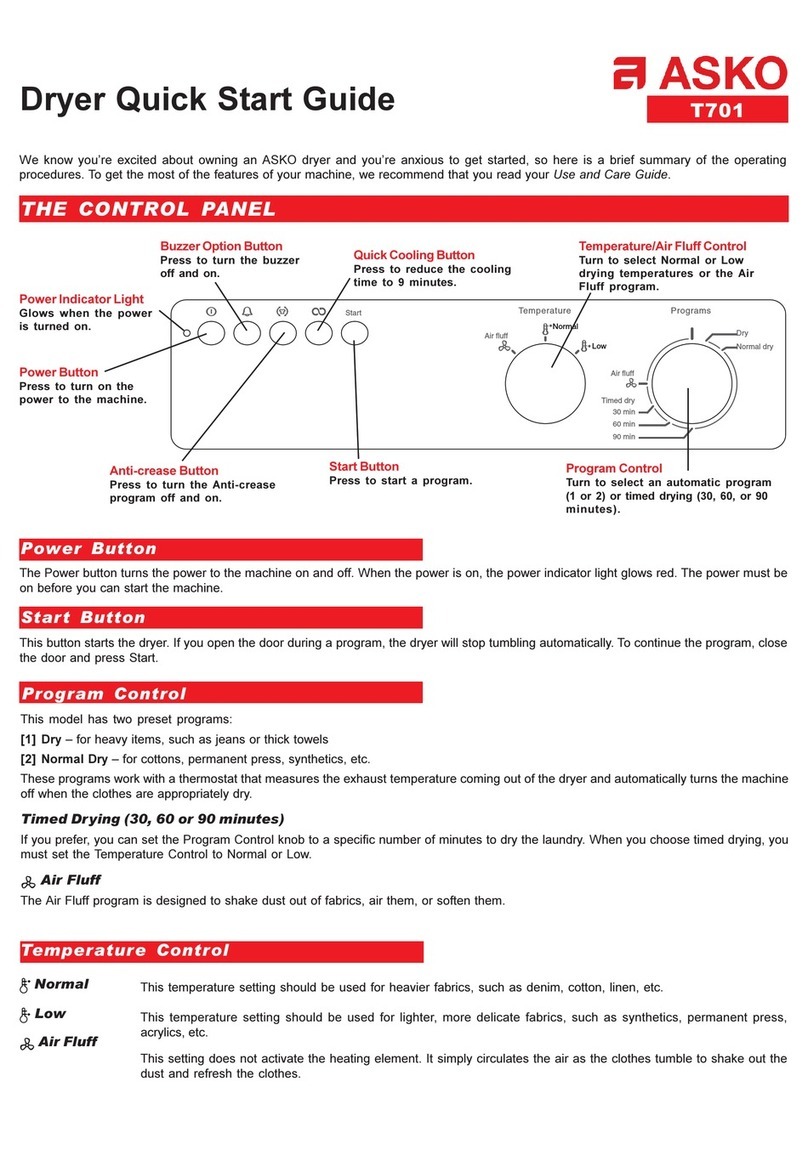

Contents

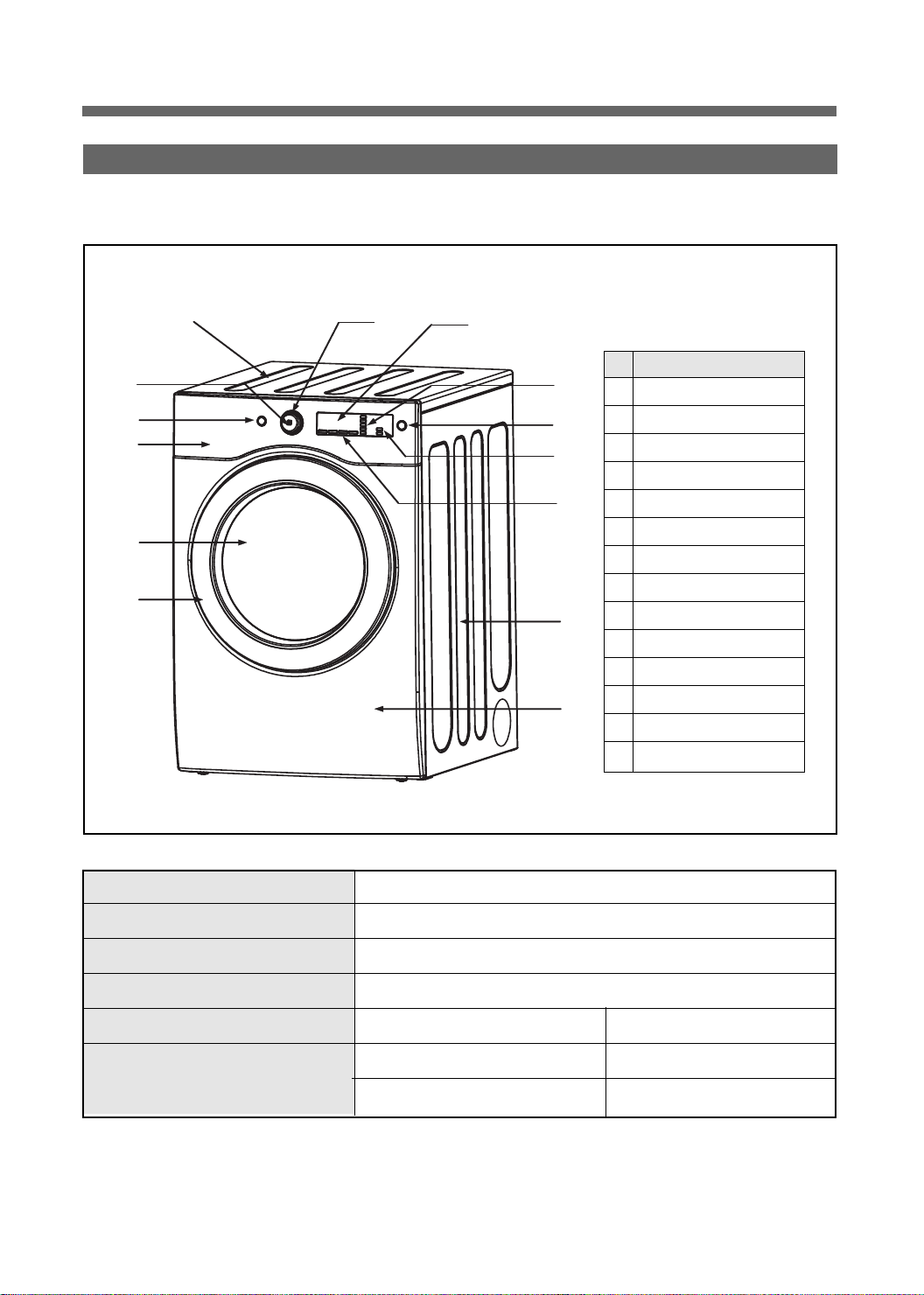

❏ What is a Dryer? .................................................................................................................................................................2

❏ Dryer Specification..............................................................................................................................................................4

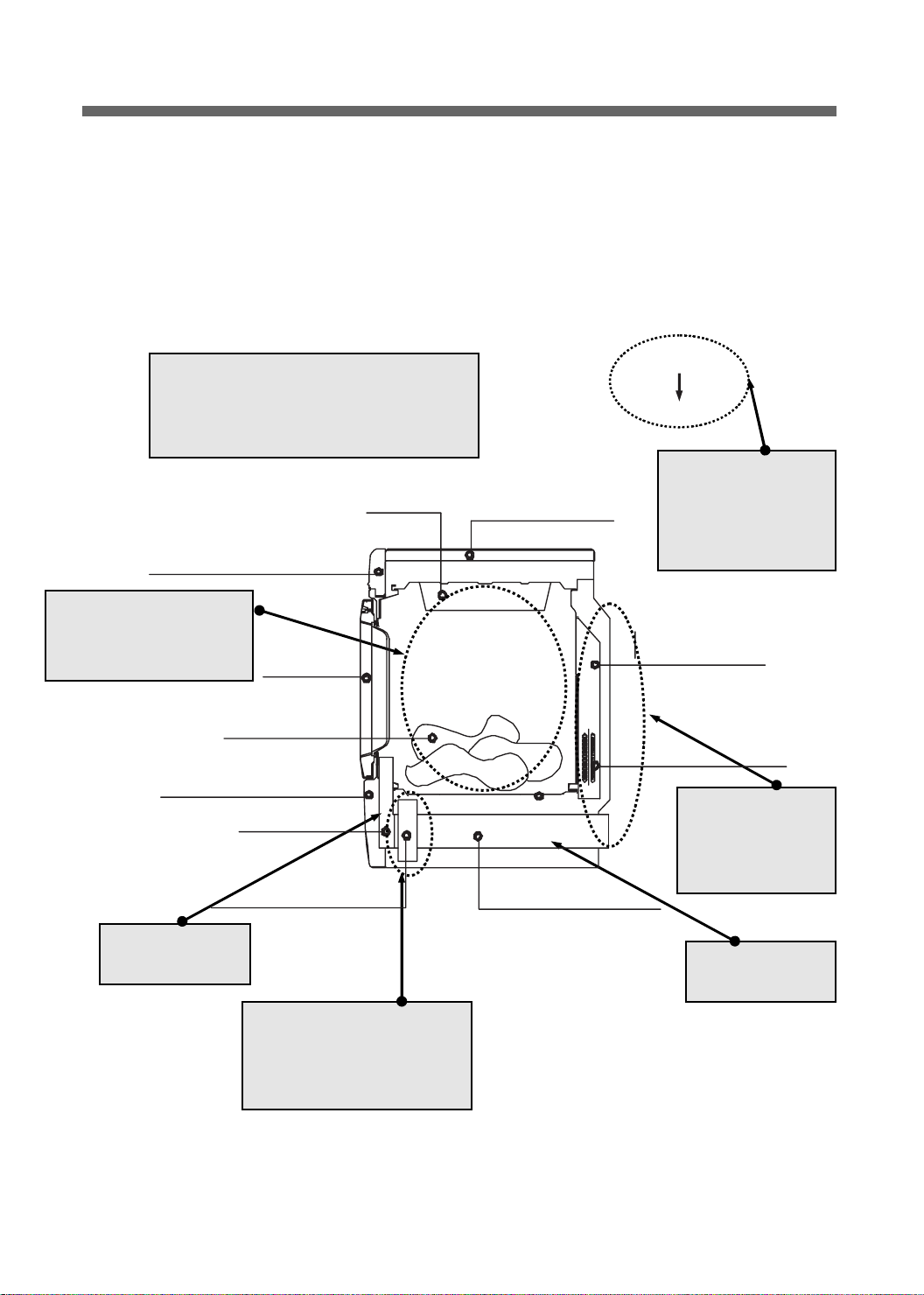

❏ Operating Mechanism Diagram (Gas Type).....................................................................................................................5

❏ Operating Mechanism Diagram (Electric Type)................................................................................................................6

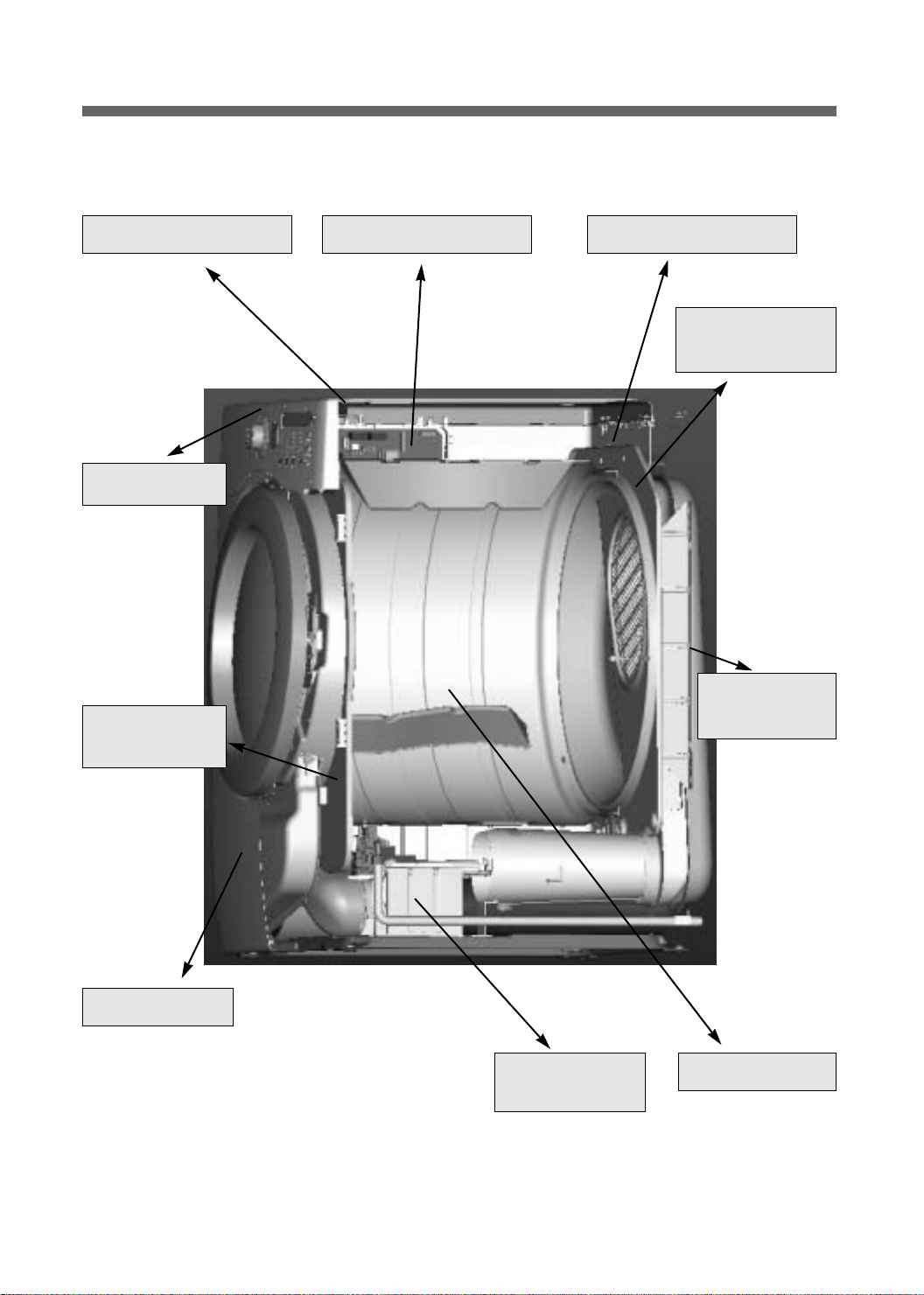

❏ Mechanism by Ass’y (Electric Type)..................................................................................................................................7

❏ Mechanism by Ass’y (Gas Type).......................................................................................................................................8

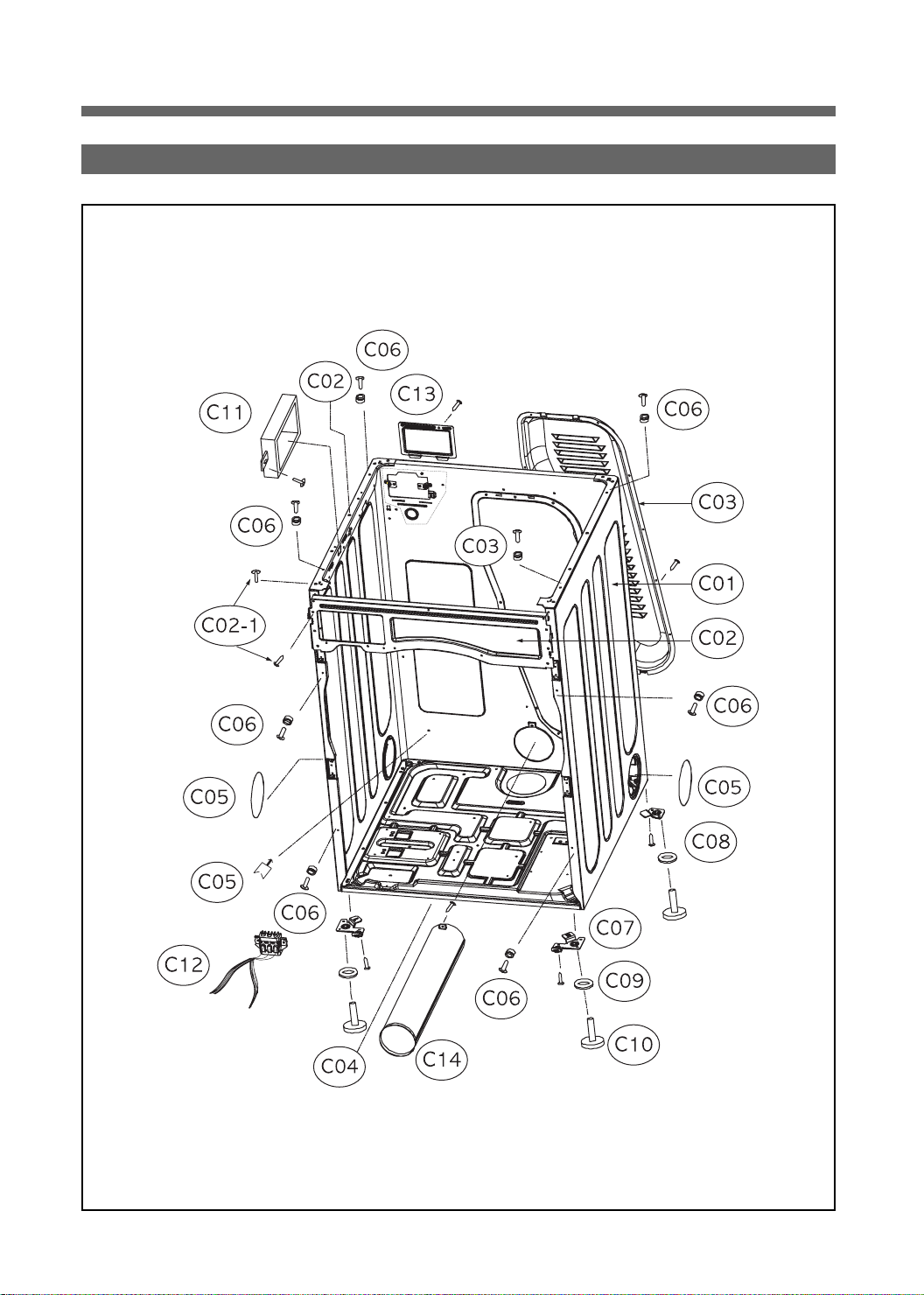

❏ Parts List by Ass’y...............................................................................................................................................................9

❏ PCB Function Specification .............................................................................................................................................23

❏ Drum Dryer Troubleshooter .............................................................................................................................................37

❏ Dryer Installation ...............................................................................................................................................................41

❏ Electrical Requirements For Electric Dryers....................................................................................................................42

❏ Dryer Service Notices ......................................................................................................................................................49

❏ Electric Parts List - Electric Clothes Dryer.......................................................................................................................50

❏ Electric Parts List - Gas Clothes Dryer

Thermostat Fan...................................................................................................................................................................................51

Thermostat Cut-Out............................................................................................................................................................................52

Thermostat Hi-Limit.............................................................................................................................................................................53

Lamp Assembly ..................................................................................................................................................................................54

Switch Door.........................................................................................................................................................................................55

Heater Assembly.................................................................................................................................................................................56

Belt Switch (Switch Micro)..................................................................................................................................................................57

Thermistor Fan....................................................................................................................................................................................58

Motor Dryer..........................................................................................................................................................................................59

Igniter As..............................................................................................................................................................................................61

Flame Sensor......................................................................................................................................................................................62

Thermostat Hi-Limit.............................................................................................................................................................................63

Thermostat Cut-Out............................................................................................................................................................................64

Valve Gas As ......................................................................................................................................................................................65

❏ Dismantling Method Per Dryer Ass'y

PANEL FRONT ASS’Y / PLATE TOP ASS'Y...................................................................................................................................66

CABINET FRONT ASS'Y...................................................................................................................................................................67

FRAME UPPER / SEPARATION OF LAMP,PCB MAIN CONNECTOR.......................................................................................68

PCB MAIN / DUCT OUTLET ASS'Y.................................................................................................................................................69

SUPPORT DRUM FRONT ASS'Y / DRUM ASS'Y / PIPE EXHAUST...........................................................................................70

COVER BACK / SUPPORT DRUM REAR ASS'Y...........................................................................................................................71

MOTOR CONNECTOR.....................................................................................................................................................................72

TERMINAL BLOCK............................................................................................................................................................................73

MOTOR ASS'Y...................................................................................................................................................................................74

HEATER ASS'Y / LAMP ASS'Y.........................................................................................................................................................76

FILTER DUST ASS'Y / HUMIDTY SENSOR...................................................................................................................................77

DOOR ASS'Y......................................................................................................................................................................................78

GAS BURNER ASS'Y........................................................................................................................................................................80