Aspect LED AL-SL-WN-S-RGB User manual

PROFESSIONAL GRADE LED LIGHTINGTM

Color Changing LED Strip

Lights Installation Guide

Copyright © 2012-2016. aspectLED, Inc. 1

www.aspectled.com

OVERVIEW

aspectLED’s Flexible LED strip lights are a perfect solution for a wide variety of architectural and accent lighting

applications including; cove lighting, under-cabinet lighting, back-lighting, pathway lighting and decorative lighting.

Our exible LED strip lights are made with wire leads on both ends of each 16.4’ reel and can be cut at desig-

nated cut points, allowing you to cut pieces to the exact length that you need.

MODELS

Color Changing LED Strip

Lights Installation Guide

Copyright © 2012-2016. aspectLED, Inc. 2

W-Series RGB Ultra Bright

Distance between LEDs: 1/2” (12mm)

LED Quantity: 18 LEDs per foot (300 per reel)

Water-proong SKU Dimensions Input Voltage Cut Length

Non-waterproof AL-SL-WN-U-RGB

3/8” (10mm) wide

1/16” (2mm) thick

16.4’ (5M) long

12VDC 2” (50.8mm)

24VDC 4” (100.16mm)

Water resistant AL-SL-WR-U-RGB

3/8” (10mm) wide

1/8” (3mm) thick

16.4’ (5M) long

12VDC 2” (50.8mm)

24VDC 4” (100.16mm)

Waterproof AL-SL-WW-U-RGB

1/2” (12mm) wide

1/4” (5.4mm) thick

16.4’ (5M) long

12VDC 2” (50.8mm)

24VDC 4” (100.16mm)

W-Series RGB Standard Bright

Distance between LEDs: 1-1/16” (27mm)

LED Quantity: 9 LEDs per foot (150 per reel)

Water-proong SKU Dimensions Input Voltage Cut Length

Non-waterproof AL-SL-WN-S-RGB

3/8” (10mm) wide

1/16” (2mm) thick

16.4’ (5M) long

12VDC 4” (100.16mm)

24VDC 6-1/2” (165.1mm)

Water resistant AL-SL-WR-S-RGB

3/8” (10mm) wide

1/8” (3mm) thick

16.4’ (5M) long

12VDC 4” (100.16mm)

24VDC 6-1/2” (165.1mm)

Waterproof AL-SL-WW-S-RGB

1/2” (12mm) wide

1/4” (5.4mm) thick

16.4’ (5M) long

12VDC 4” (100.16mm)

24VDC 6-1/2” (165.1mm)

Copyright © 2012-2016. aspectLED, Inc. 3

Color Changing LED Strip

Lights Installation Guide

W-Series RGBW Ultra Bright

Distance between LEDs: 1/2” (12mm)

LED Quantity: 18 LEDs per foot (300 per reel)

Water-proong SKU Dimensions Input Voltage Cut Length

Non-waterproof AL-SL-WN-U-RGBW

1/2” (12mm) wide

1/16” (2mm) thick

16.4’ (5M) long

24VDC 6-1/2” (165.1mm)

Water resistant AL-SL-WR-U-RGBW

1/2” (12mm) wide

1/8” (3mm) thick

16.4’ (5M) long

24VDC 6-1/2” (165.1mm)

Waterproof AL-SL-WW-U-RGBW

9/16” (14mm) wide

3/16” (4.7mm) thick

16.4’ (5M) long

24VDC 6-1/2” (165.1mm)

W-Series RGBA Ultra Bright

Distance between LEDs: 1-1/8” (28.2mm)

LED Quantity: 9 LEDs per foot (150 per reel)

Water-proong SKU Dimensions Input Voltage Cut Length

Non-waterproof AL-SL-WN-U-RGBA

3/8” (10mm) wide

1/16” (2mm) thick

16.4’ (5M) long

24VDC 6-1/2” (165.1mm)

Water resistant AL-SL-WR-U-RGBA

3/8” (10mm) wide

1/8” (3mm) thick

16.4’ (5M) long

24VDC 6-1/2” (165.1mm)

Waterproof AL-SL-WW-U-RGBA

1/2” (12mm) wide

3/16” (5.4mm) thick

16.4’ (5M) long

24VDC 6-1/2” (165.1mm)

Copyright © 2012-2016. aspectLED, Inc. 4

Color Changing LED Strip

Lights Installation Guide

Tape Measure Wire Stripper Screw Driver

TOOLS YOU’LL NEED

Scissors

BEFORE YOU BEGIN

We know how boring it can be to read instructions, so we’ll keep this installation guide as short and sweet as

possible. Before you begin with your installation, be sure to fully read these instructions. They contain many

useful tips and pointers that will help to ensure a perfect installation, save you time, and ensure your safety.

SPECIFICATIONS

Input Voltage 12VDC or 24VDC

Power Consumption Model Dependent

Ambient Temperature -40°F~140°F (-40°C~60°C)

Beam Angle 120°

Maximum Run

16.4 feet @ 12VDC

32 feet @ 24VDC

Copyright © 2012-2016. aspectLED, Inc. 5

Color Changing LED Strip

Lights Installation Guide

IMPORTANT CONSIDERATIONS

• LED strip lights must be powered by a compatible aspectLED constant voltage driver (available at www.

aspectled.com).

• DO NOT power strip lights while tightly coiled or attached to reel.

• DO NOT install strip lights where LED chips are exposed to direct sunlight.

• Always consult a wire gauge chart to determine the correct size wire for your application. Wire gauge is

dependent on voltage drop, amperage rating, and environment. Incorrect wire selection could overheat

systems and cause a re.

• Only waterproof strip light models are rated for use outdoors where it will be exposed to rain, humidity or

moisture. Water resistant xtures are only for use indoors near a location where occasional splashes may

occur, not submersion.

• This product is suitable for environments of ambient temperatures between -40°F to 122°F (-20°C to 50°C).

It is important that LED strip lights are not installed outside this range. Always make sure there is adequate

airow and available heatsink when installing.

• DO NOT bend LED strip lights to a diameter less than the width of your thumb.

• DO NOT crease LED strip lights.

• DO NOT put pressure on surface of strip lights, especially on the glass/acrylic panes.

• DO NOT cover strip lights with any materials other than any mounting accessories if applicable.

It is important that you install this product (and all other electrical products) in accordance with the National

Electric Code (NEC) and all applicable local building and electrical codes for your area. If you are unfamiliar with

the NEC, your local building/electrical codes, and/or the proper installation methods for electrical devices, you

should hire a qualied and licensed electrician to do the work for you.

Before beginning any electrical work, always disconnect power at the fuse or circuit breaker.

Copyright © 2012-2016. aspectLED, Inc. 6

Color Changing LED Strip

Lights Installation Guide

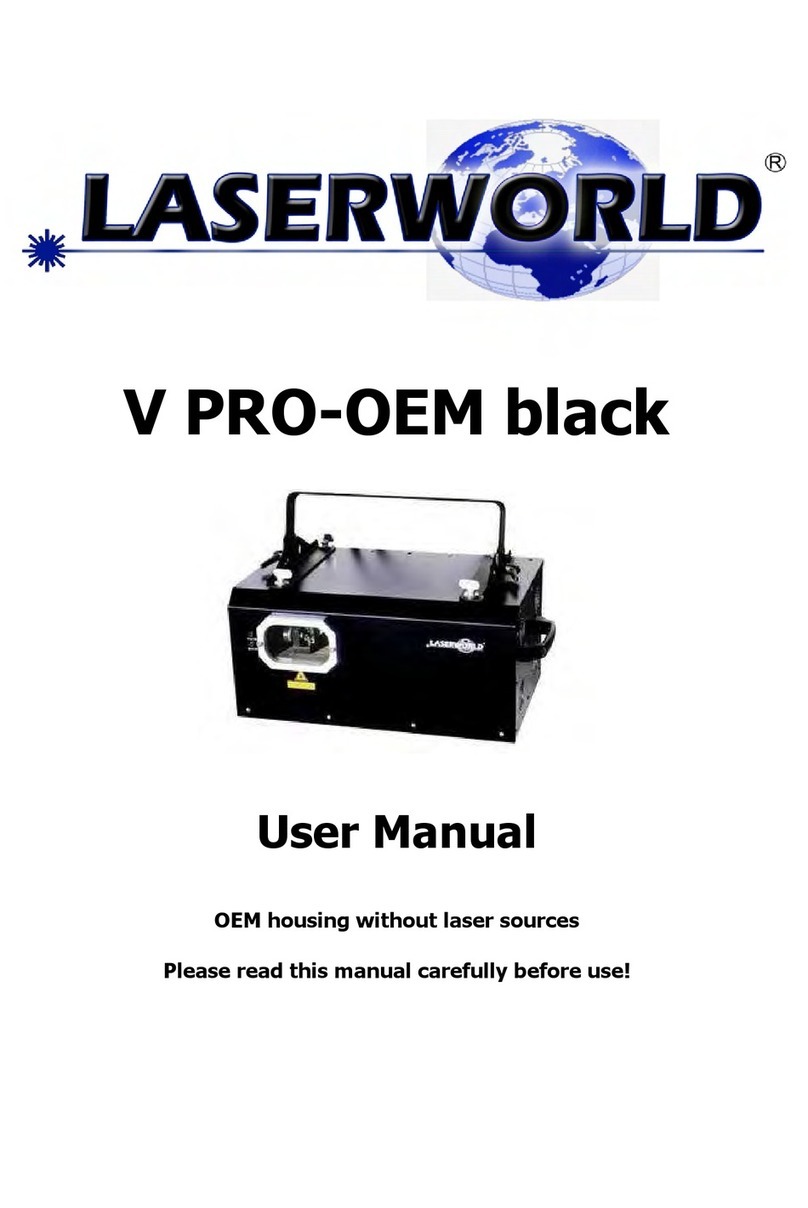

STRIP LIGHT HANDLING

Don’t bend LED strip light to a

diameter less than 1.5 inches.

Don’t fold or crease LED strip light. Don’t tightly bend LED strip light

on a horizontal plane.

Don’t apply excessive pressure to

surface of strip light.

Never cover strip light with any

materials.

Don’t power strip light while still

on its reel or while tightly coiled.

Copyright © 2012-2016. aspectLED, Inc. 7

Color Changing LED Strip

Lights Installation Guide

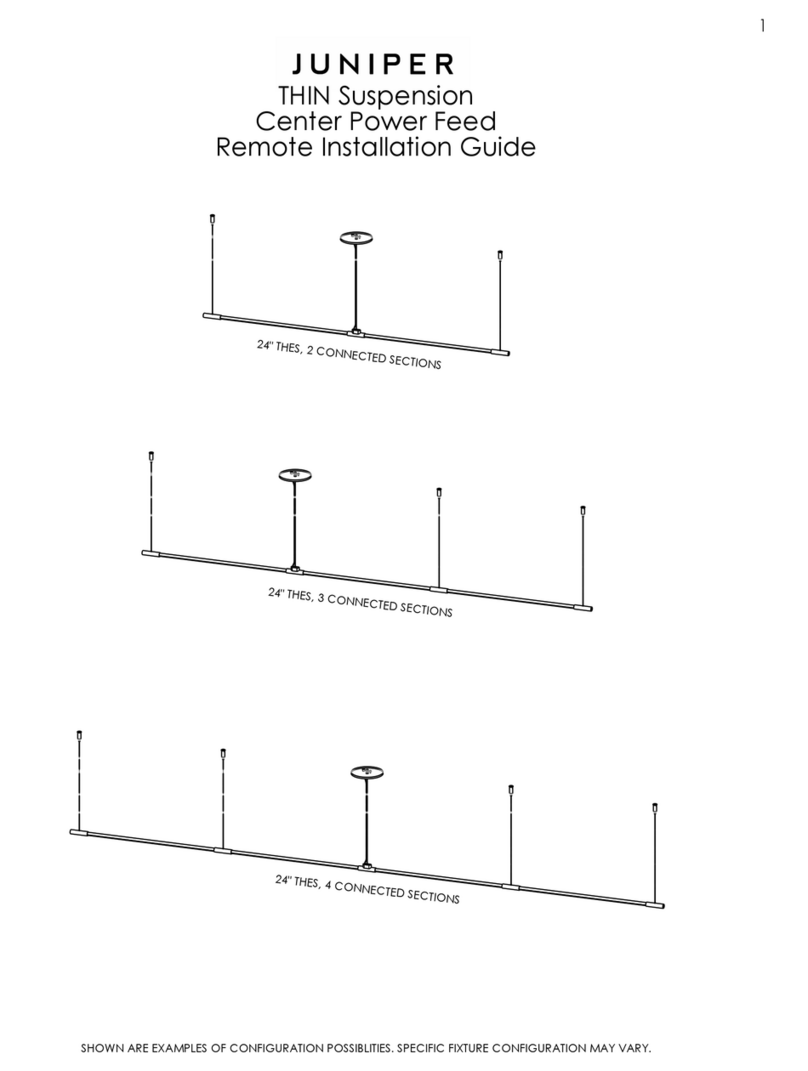

SYSTEM DIAGRAM

PLUG-IN ADAPTER SYSTEM

DMX SYSTEM

Copyright © 2012-2016. aspectLED, Inc. 8

Color Changing LED Strip

Lights Installation Guide

1. Determine a suitable location to install the 3 components as labeled in System Diagram

WIRING CONNECTIONS

INSTALLATION

Only cut the strip on a marked cut line,

these are located on the center of each set

of copper soldering pads.

Controls Power Supply LED Light Fixture

This will include suitable wire installed between the power supply, the LED light xture, and any controls.

It is important to choose the correct wire for the specic application, this is dependent on voltage drop,

amperage rating, and environment. Please consult a voltage drop and wire sizing chart to determine

adequate wire size. Using the incorrect wire size will damage your products! If installing wiring in a wall or

ceiling, always use in-wall rated wiring.

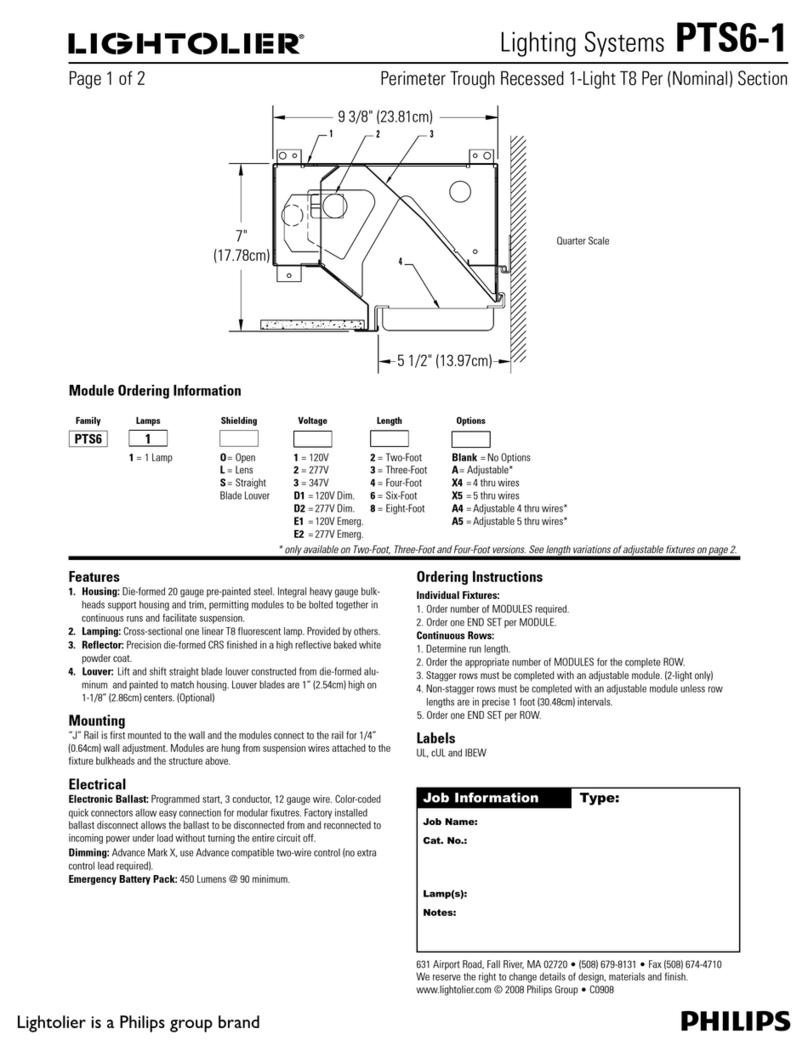

2. Cut strip lights to desired length at the designated cut points on the strip (dependent on model). If you

need to connect more than one strip together, you may choose to solder the connections together.

a. Special consideration is needed for altering the length of the water resistant and waterproof

strips. It is important to carefully remove the protective silicone coating and to re-waterproof

using Silicone End Caps (available at www.aspectled.com) and silicone after making the cut. Be

sure to note the location of the polarity (+/-) markings before soldering. Use lead-free stranded

18-20 gauge copper wire between any copper soldering pad along the strip.

Copyright © 2012-2016. aspectLED, Inc. 9

Color Changing LED Strip

Lights Installation Guide

b. Verify that your strip light is acceptable for use in wet locations by looking for a “approved for

wet location” label on the outside of the product packaging. Remember that only the strips are

approved for wet locations (power supplies and connectors are not approved unless stated). Cut

strip to length, then, using a razor blade, carefully remove the silicone jacket to provide access to

the copper solder pads. Solder your wires to the strip(s). Fill an end-cap with silicone and carefully

slide the end cap over the wires (you may need to poke small holes for the wires) securing it

rmly against the strip light. Wipe o any excess silicone and allow to dry before connecting

power or submerging.

Flexible Strip Light Connector with

Connector on One End

Flexible Strip Light Connector with

Connector on Both Ends

Flexible Strip Light Splice Connec-

tor with No Wires

3. Clean and dry the area that you would like to mount your xture. Mount the strip light to your desired

surface using either the adhesive backing (only available on non-waterproof and water resistant strips),

adhesive caulk, or Silicone Mounting Straps (available at www.aspectled.com).

c. If you are using the non waterproof strips, quick connectors such as the Flexible Strip Light

Connectors (used to round 90° bends) or Flexible Strip Light Splice Connectors are available at

www.aspectled.com.

Copyright © 2012-2016. aspectLED, Inc. 10

Color Changing LED Strip

Lights Installation Guide

a. When installing using the adhesive backing, press from one end to the other to prevent air

pockets or raised sections. Be careful to limit contact with skin to ensure a minimal transfer of oil

from skin to LED strip backing.

b. If installing with an Aluminum Mounting Channel for Flexible Strip Lights, be sure to choose

the correct size (narrow or wide channel) for your strip. Channels are best mounted using the

included specially designed brackets. More information about channels/tracks can be found at

www.aspectled.com.

4. Attach the power supply and any controls by referring to the System Diagram and installation guides for

both the drivers and dimmers available at www.aspectled.com.

a. Remember to use suitable copper wiring between all components by referring to a voltage drop

and wire sizing chart.

5. Once you’ve nished, double check all connections and turn on power to your circuit. Test functionality

of your installation. If you experience issues, see the trouble shooting guide on page 11, or contact

6. Congratulations! You’ve successfully completed the installation process. Once your light is installed, your

project is nished. Now is a great time to take a moment to sit down and enjoy your favorite beverage

while giving yourself a pat on the back for a job welldone.

Copyright © 2012-2016. aspectLED, Inc. 11

Color Changing LED Strip

Lights Installation Guide

TROUBLESHOOTING

Shift in brightness and/or

temperature

• Make sure you did not exceed the maximum series run limit. This will cause

excess voltage drop, resulting in decreased brightness and/or temperature as

the run is extended.

Some lights are not

functional

• Ensure all connections have been attached properly. Make sure that the strips

have not been bent excessively, which may cause components and solder to

detach from the circuit board.

Lights are ickering • Check that a compatible driver is installed. Ensure controller is not on dynam-

ic mode. Verify that +/- connections of DMX systems are not reversed.

• Check for loose connections and that strip light connectors are attached cor-

rectly. Strips vary in width so it is important that compatible models are used

and consistent polarity is maintained.

Lights are turning on/o

repeatedly

• Ensure the driver is not overloaded. An overloaded driver will trip the inter-

nal auto-reset repeatedly, turning the system on/o.

Installation trips main

breaker

• Check wiring for a short circuit. If breaker continues to trip, there might

be a short in your circuit. Call us at (888) 503-1317 option 3 or email us at

HAVE QUESTIONS OR NEED ASSISTANCE?

We’re always here to help!

This manual suits for next models

11

Table of contents

Other Aspect LED Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Hopkins

Hopkins BLAZER LINK CWL623 owner's manual

IMG LIGHTING

IMG LIGHTING GARNET L user manual

TowMate

TowMate TM16UP-A Guide to operations

Endon

Endon Hammersmith instruction manual

HUBBELL LIGHTING

HUBBELL LIGHTING Dual Lite CCU2 Series installation manual

DCbright

DCbright DARK LICHT Series operating instructions