3 of 12

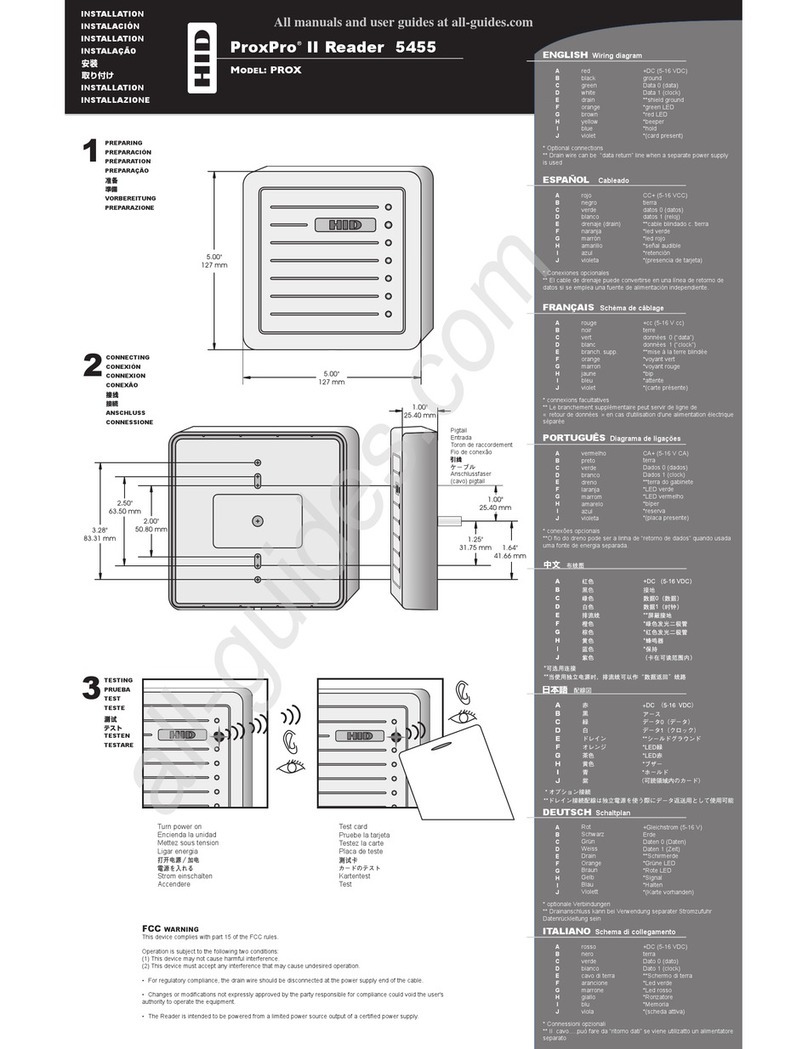

Wiring the DR100 – Terminal Blocks

J2 Input Terminals

1 Privacy NO (Not Used)

2 Privacy COM (Not Used)

3 DX NO (Not Used)

4 DX COM (Not Used)

5 REX NO (Not Used)

6 REX COM (Not Used)

7 DPS 2 NO**

8 DPS 2 COM**

9 DPS 1 NO**

10 DPS 1 COM**

**NOTE: Both DPS 1 and DPS 2 need to be closed

in order for the EAC to see a DPS secure signal. The

unit comes with a jumper pre-installed to close

DPS 1. If using only one DPS, install into DPS 2.

If using two DPS, remove the jumper in DPS 1

and install each DPS individually to DPS 1 and

DPS 2. Wireless communication of DPS 1 and

DPS 2 have not been evaluated to UL294.

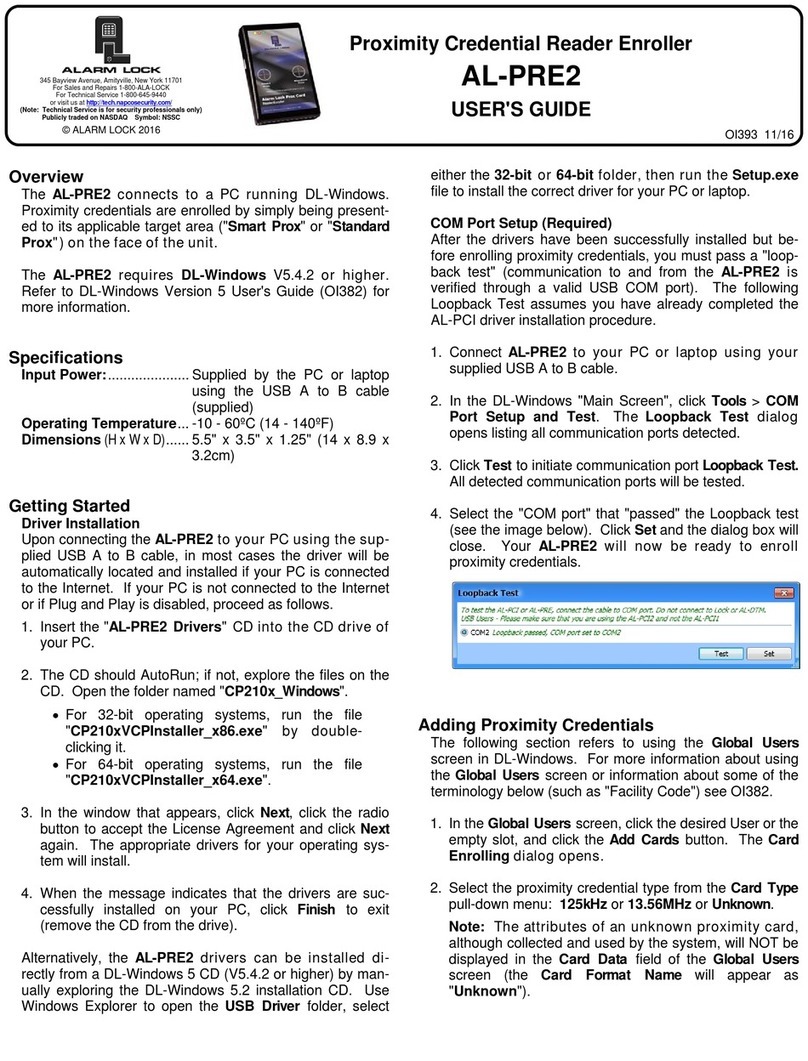

Diagram 4

Relay 2 Sect Jumper Timing

Relay 1 and 2 actuate simultaneously

Relay 2 and 3 actuate simultaneously

Relay 2 Sect Jumper Delay Timing

Delay only applies to RELAY 3

(factory default)

Delay applies to both

RELAY 2 and RELAY 3

J1 Output/Power Terminals

1 12-24 VDC

2 Relay COM 1

3 Relay NO 1

4 Relay NC 1

5 Relay COM 2

6 Relay NO 2

7 Relay NC 2

8 Relay COM 3

9 Relay NO 3

10 Relay NC 3

11 GND

12 GND

Make wire connections at the appropriate

wire terminal with Relay Secure Board seated

in housing. Removal of the Relay Secure

Board from housing is not recommended.

WET

DRY

P1

S2

P4

P5P6

1

2

3

P2 P3

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10

WET

DRY

WET

DRY

RLY 1 RLY 2 RLY 3

RELAY 3 DECAY SELECT RELAY 2 SELECT

R LY 1 & 2

R LY 2 & 6

1 2 3

WET

DRY

P1

P2 P3

1 2 3 4 5 6 7 8 9 10 11 12

WET

DRY

WET

DRY

RLY 1 RLY 2 R LY 3

RELAY 3 DECAY SELECT RELAY 2 SELECT

R LY 1& 2

R LY 2 & 6

1 2 3

P4

1

2

3

P2 P3

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10

WET

DRY

WET

DRY

RLY 1 RLY 2 R LY 3

RELAY 3 DECAY SELECT

RELAY 2 SELECT

R LY 1& 2

R LY 2 & 6

1 2 3

Relay 1

WET/DRY

Jumper

Relay 2

WET/DRY

Jumper

Relay 2 Select Jumper

Dip Switches

Relay 3

WET/DRY

Jumper

Wet/Dry Jumper Settings

Wet/Dry jumper settings can be

configured to set each individual

relay to be a wet or dry contact.

• When set as a WET CONTACT, the

relay will provide direct power to

the device connected to the relay

from the power source connected

to the Relay Secure Board.

• When set as a DRY CONTACT, the

relay will not provide direct power

to the device. Use this setting if

the device is powered externally.

• The voltage supplied to an external

device through a wetted relay

will be equivalent to the voltage

supplied to the relay board.

Delay Settings

The Delay setting is used to delay the

actuation between RELAY 1 and 3.

• The Delay will only apply to RELAY 3

if the RELAY 2 Select jumper is in the

left position. The delay will apply to

both RELAY 2 and 3 if the RELAY 2

Select jumper is in the right position.

• The delay time is configurable

via the dip switch settings on

the Relay Secure Board.

Relay 2 Jumper Settings

The Relay 2 will always actuate

simultaneously with either

Relay 1 or Relay 3.

• To configure RELAY 2 to actuate

simultaneously with RELAY 1 move the

jumper to left position so it is covering

pins 1 and 2 (default configuration).

• To configure RELAY 2 to actuate

simultaneously with RELAY 3

move the jumper to right position

so it is covering pins 2 and 3.