2

SPECIFICATIONS

Cabinet Dimensions:

Height: 17 inches Width: 14 inches Depth: 28 inches

ShippingWeight ........................ 108 Lbs..

Line Under voltage Alarm Point ............. 90VAC

StarterCurrentAvailable ................350 Amps.

Alternator Load .......................... 8Amps

MotorHP ..... ½HP(1HPOptional) Continuous Duty

MotorProtection ......AutomaticResetCircuitBreaker

Power Requirements ......120 VAC, 60 Hz., 20 Amps

Additional Features:

a) A sturdy, oversized “V” block with an easily

adjustable cast aluminum vise holds both

Alternators and Starters firmly and safely in

place during testing.

b) Slim-line design, heavy gauge steel cabinet and

base. Only 14 inches wide to maximize usable

bench top work space. Modular construction.

c) Constant voltage, current regulated solid-state

power supply with overload protection. A solid-

state voltage regulator correctly simulates actual

vehicle voltage conditions. No contacts to burn

or to wear out.

d) A ½ HP (1 HP Optional) continuous duty

industrial motor - clockwise or counter clockwise

rotation, automatic reset circuit breaker

protected.

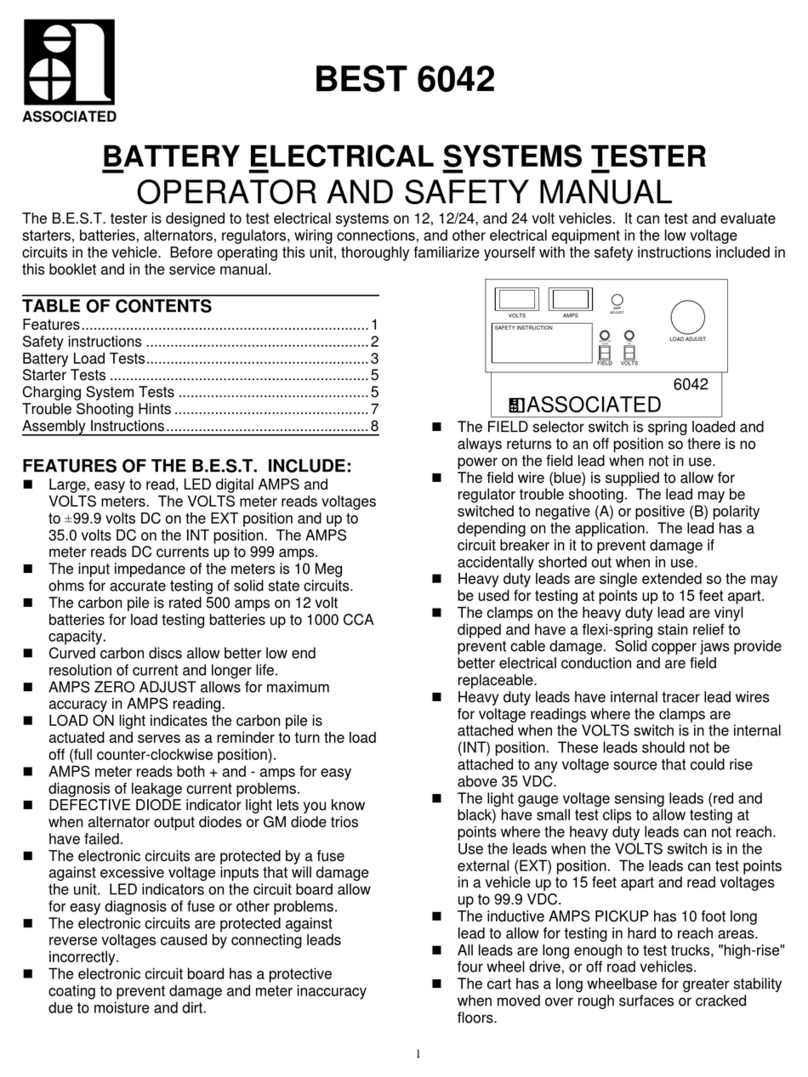

Control Function Descriptions

Starter Test Switch - Used to energize Starters.

Power - On/Off Switch - Main power switch. Used to

turn on the unit; allows all tests to be performed.

Drive Motor Switch - Activates drive motor - Press

switch up for clockwise (CW) rotation units, down for

counter-clockwise (CCW) rotation units. Note: Most

Alternators will operate correctly in either direction.

Volt-Amp. Meter - In VOLTS mode indicates the

charging voltage (under load) of the Alternator or the

Generator (if so equipped with optional Generator Test

Lead Module). The VOLTS mode indicates alternator

DC output voltage; the AMPS mode shows starter free

running amperage draw. Unit automatically selects the

mode needed (VOLTS/AMPS).

Stator-Relay LED - Indicates proper operation of stator

or relay output terminal (if Alternator is so equipped).

LED brilliance may vary from alternator to alternator.

Alternator LED - Functions the same as the Alternator

lamp in the vehicle.

Trio LED - This LED is used primarily with the Delco 1-2

plug and other Alternators with internal regulators -

disregard it on all other types of Alternators.

Diode LED - When the LED is on, reject the Alternator.

Illumination is caused by excess ripple (AC).

Safety Interlock Switch - This safety switch is

controlled by the belt guard position. When the belt

guard is up, the Drive Motor Switch is inoperative.

DO NOT, UNDER ANY CIRCUMSTANCES, ATTEMPT

TO BYPASS THE OPERATION OF THIS INTERLOCK

!!

Fuse - This fuse is for the DC Alternator current supply.

Replace only with a 15 Amp. fuse (AGC-15). Failure to

replace it with the correct fuse may cause damage to the

tester and will void factory warranty.

Voltage Switch - Switch up for Alternators being tested

at 12 volts. Switch down for Alternators being tested at

24 volts. (This switch applies to Alternator/Generator

voltages only.)

Generator testing is done in the same manner if

equipped with an optional Generator Test Lead Module.

6 Volt Generators are tested in the 12 Volt mode by

dividing the voltage reading in half to give the operator a

correct reading.

Short/Low Voltage LED - If the LED turns on and an

audible alarm sounds the Alternator is either shorted or

the hook up is incorrect, thus causing a short circuit in

the battery or the field circuit. If the LED turns on and an

audible alarm sounds when testing Starters, the starter

is either shorted or the power line voltage to the test

bench is too low to perform a valid test

Ignition LED - Indicates proper operation of the auto

ignition system while starting. (Applicable on solenoids

having this terminal connection.)

A-B Switch - Switch up for “A” circuit - Switch down for

“B” circuit. Consult the operating instructions for proper

position.

Lead Socket - Socket for the Universal Lead Set of

Alternator test wires (For the Generator Test Lead

Module as well, if so equipped.)