1

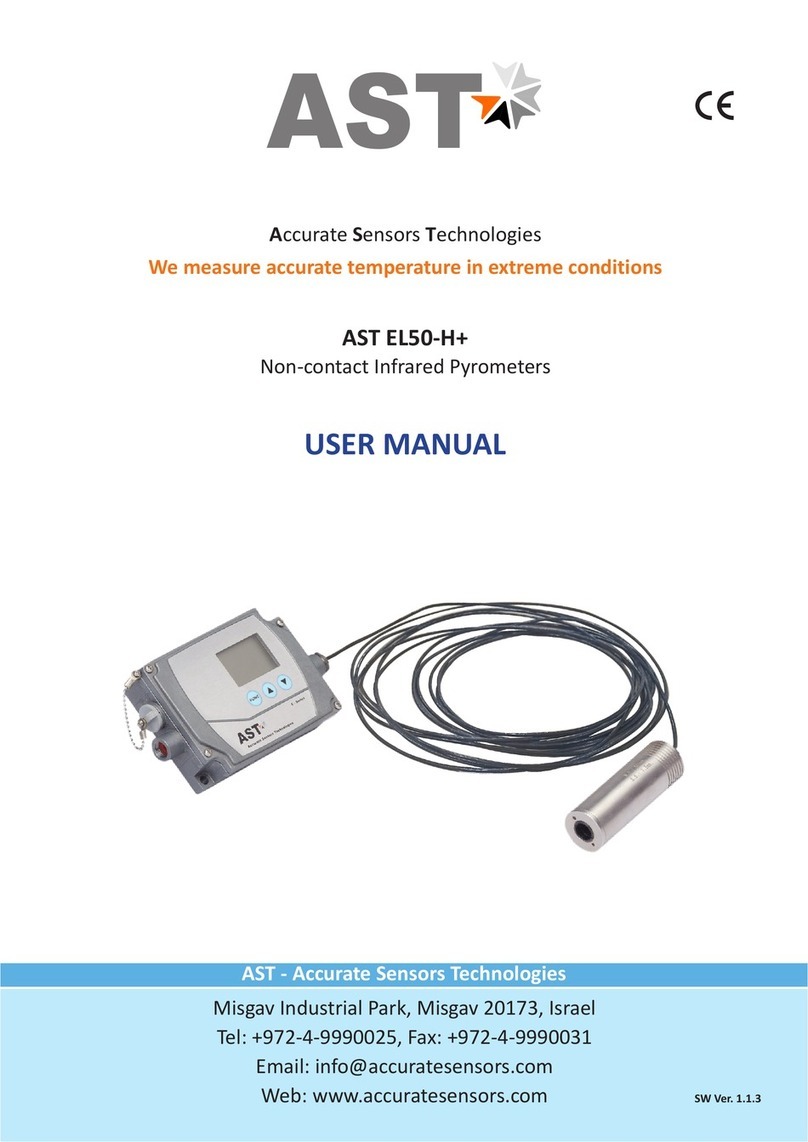

Accurate Sensors Technologies

AST

Chapter-1

General Information

We are pleased that you have chosen this high quality and highly efficient AST pyrometer for non-contact

temperature measurement.

Please read this manual carefully, step by step before performing any operation with the Pyrometer. It

contains all the necessary instructions for set up and operation of the pyrometer. When operating the instrument, it

is necessary to follow the general safety instructions. All general information regarding handling, cleaning, and

maintenance of pyrometer are offered according to best of our knowledge & experience.

1.1 Safety Measures

This section provides an overview about important safety regulations.

1.1.1 General

Each person working with the pyrometer must have read the user manual before operation. The Pyrometer

has only to be used for the purpose described in the manual.

1.1.2 Safety Precaution

The Pyrometer works only with a potential-free low voltage of range 24V DC. This voltage is not harmful for

the user.

1.1.3 Maintenance and use of Pyrometer

Pyrometer can be operated by the qualified person who has got instructions from the supervisor. It is strongly

prohibited to do technical modifications of the device without permission of the manufacturer.

1.1.4 Environmental Protection

The lens or its coating may contain harmful materials and hence it should not be disposed of with normal

waste.

1.1.5 Packaging and storage

Always use a shock-proof package for shipment of the pyrometer. It should be sealed to protect it against

humidity. Also protect the lens of the pyrometer with a cover. They should be stored at the temperature ranges from

-20° to +70° C.

1.1.6 Warranty

AST 450 G-2 instruments have a warranty of two years from the invoice date. AST will replace defective parts,

which arises from design errors or manufacturing faults. In case, if pyrometer is opened, disassembled or modified

then the guarantees will loss.

AST does not accept liability for any damage or losses which might occur, including consequential damages

and financial losses, as a result of use of the equipment.

1.1.7 Copyright ©

© All rights reserved. This document may contain proprietary information and shall be respected as a

proprietary document to AST with permission for review and usage given only to the rightful owner of the

equipment with which this document is associated.