2

AST A450C FO-PL is specially designed highly accurate digital two color pyrometer with fiber optic to provide high

performance and low maintenance of non contact temperature measurement in demanding industrial environment.

They are designed for areas with high ambient temperature (upto 250°C) without cooling or in areas where strong

electromagnetic interference can influence correct measurement because the fiber & optical head do not contain

any electronic part.

2.1 Application, Range and Working Principle

AST A450C FO-PL is highly accurate two color pyrometer with fiber optics especially designed for rough industrial

environment for temperature measurement of metals, ceramic or graphite. They are suitable for high temperature

measurement ranging from 800°C to 3200°C.

AST A450C FO-PL pyrometers are suitable for industrial purpose due to following advantages:

Ÿ Measurement of temperature is not affected by emissivity of object.

Ÿ Measurement of object temperature is possible where dust, moisture & other contaminants are present in

surrounding environment.

Ÿ The measuring object can be smaller than spot size.

Ÿ The pyrometer can be switched between 1-colour & 2-colour mode.

These pyrometers have solid body in stainless steel housing which provides high operation safety even in rough

industrial environment, and large variety of optics with fixed focus which can be easily used in all industrial areas. The

radiation from hot object is focused on the detector by optics which then travel into mono fiber cable with flexible

stainless steel protection tube and converted into electrical signals. This signal is then linearized and converted into

standard analog & digital outputs.

AST A450C FO-PL has a fast response time of 20msec. Pyrometers have RS-232 or RS-485 outputs. Response

time, emissivity, sub range and peak picker selection can be preset ex works or adjusted through available software.

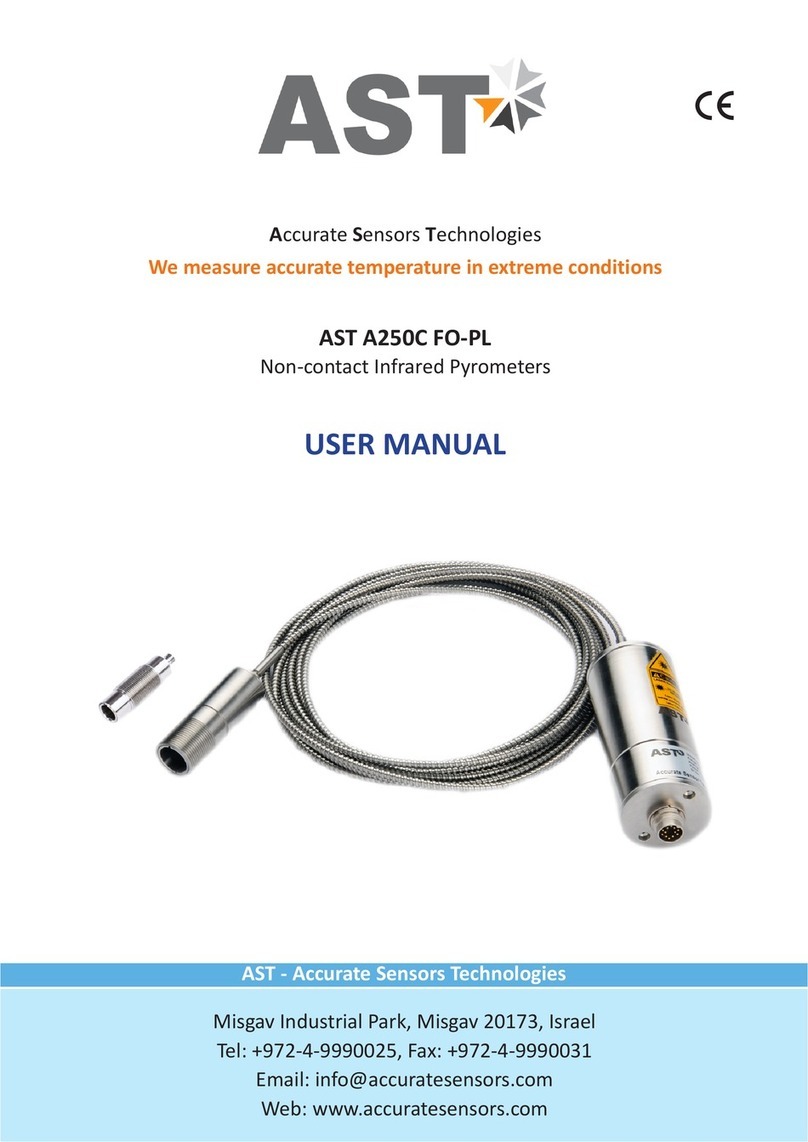

According to application there are two optical heads small (head 1) & big (head 2).The heat radiation, enter from

optical head, to the lens system & travel through mono glass fiber with flexible stainless steel protection tube where it

is transmitted along to the converted .The optical head contains only the lens system, the electronic are located in the

converter box, so the measurement is possible in atmospheric condition upto 250°C.

Two color pyrometer involves measuring thermal radiance at two different wavelengths and inferring the

temperature from the ratio of these spectral radiance. Radiance ratio thermometers can be significantly more

accurate than single band thermometers in many applications.

The applications in which AST pyrometers can be used are:

ŸInduction heating

ŸAnnealing

ŸWelding

ŸForging

ŸSintering

ŸMelting

ŸRolling mills

ŸRotary kilns

34.50 mm

Ø49.50 mm

Ø48.00 mm

Binder

Connector

SMA 905

¼” x 36

for FOC

AST A450C FO-PL

14.00 mm

Chapter - 2

Introduction

M16 x 1.0

14.50

44

OH-I

25

74.5

25

M25 x 1.5

OH-II