Aston® Tire Changer ATC-5733 User’s Manual

3

www.astontechusa.com

•Use machine correctly. Use machine in the proper manner. Never use adapters other than what is approved by the

manufacturer.

•Do not override or disable safety valves and/or devices.

•Always insure that all safety procedures are followed before any attempt is made to work on or near the equipment.

•Dress properly. Non-skid steel-toe footwear is recommended when operating machine.

•Guard against electric shock. This equipment must be grounded while in use to protect the operator from electric

shock. Never connect the green power cord wire to a live terminal. This is for ground only.

•DANGER! The motor on this machine contains high voltage. Disconnect power at the receptacle before

performing any electrical repairs. Secure plug so that it cannot be accidentally plugged in during service.

•WARNING! RISK OF EXPLOSION. This equipment has internal arcing or sparking parts which should not be

exposed to flammable vapors. This machine should not be located in a recessed area or below floor level.

•Maintain with care. Keep unit clean for better and safe performance. Follow manual for proper lubrication and

maintenance instructions. Keep control pedals and/or buttons dry, clean and free from grease and oil.

•STAY ALERT. Watch what you are doing. Use common sense. Do not use tools when you are tired or distracted

from the job at hand.

•Check for damaged parts. Check for condition of all moving parts, breakage of parts or any condition that may

affect the machines operation. Do not use if any component is broken or damaged. Replace or repair damaged or

worn parts immediately.

•Never remove safety related components or device from the machine. Do not use if safety related components are

damaged or missing.

•To reduce fire hazard, keep engine/motor exterior free of oil, solvent, or excessive grease.

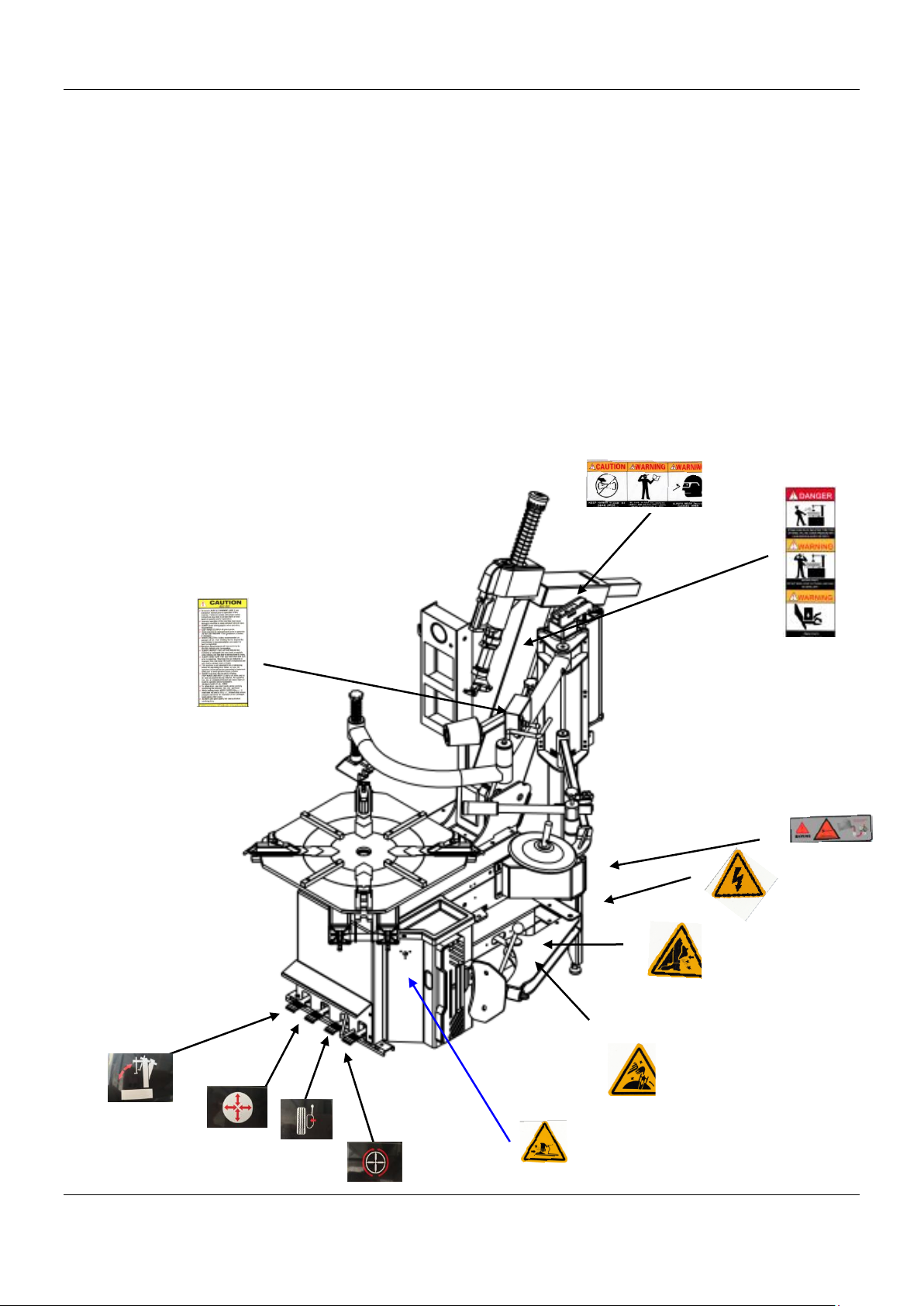

•Illegible and missing warning labels must be replaced immediately. Do not use the tire changer if one or more

labels are missing. Do not add any object that could prevent the operator from seeing the labels.

TIRE AND WHEEL SERVICE SAFETY INSTRUCTIONS

Only properly trained personnel should service tires and wheels. Read all safety and operating instructions thoroughly

before use. The following safety instructions are for one-piece wheels only.

•Always refer to the manufacturer’s procedures for multi-piece wheels.

•The machine must be connected to a power supply line circuit bracket set for 30mA.

•Always keep all working surfaces clean and free of debris.

•Always wear durable personal protective work clothing and safety gear during tire service activity.

•To avoid personal injury and/or machine damage, always make sure the tire rim is firmly secured on the tire changer

with the jaws.

•Always remove all wheel weights and the valve core to deflate the tire before servicing.

•Never place your hands between the vehicle wheel rim and the jaws during the locking/clamping stage.

•Always be aware of what each person is doing and what they will do before attempting any two-person operation.

•Always cover the electric motor and switch box before cleaning the tire changer. Be sure water or cleaner does

not enter the motor or switch box.

•Always disconnect the electric power and air supply before attempting any maintenance.