Astral Pool WATERHEAT 43506 User guide

WATERHEAT HEAT EXCHANGER

TECHNICAL MANUAL. START-UP AND OPERATION · MANUAL TÉCNICO. ARRANQUE Y FUNCIONAMENTO ·MANUEL

TECHNIQUE. MISE EN ROUTE ET FONCTIONNEMENT · TECHNISCHES HANDBUCH. INBETRIEBNAHME UND BETRIEBSWEISE ·

MANUALE TECNICO. AVVIAMENTO E FUNZIONAMENTO · MANUAL TÉCNICO. ARRANQUE E FUNCIONAMENTO

CODE: 05470205

EDITION: 13

REFERENCES

43506 (TIT-20 KW EQ)

43507 (TIT-40 KW EQ)

43508 (TIT-60 KW EQ)

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

2

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

3

TABLE OF CONTENTS……….………………………………………………ENGLISH

1. SAFETY ................................................................................................................................... 6

1.1. HEAT EXCHANGER HANDLING RISKS ............................................................................. 6

1.2. SAFETY INSTRUCTIONS AND INFORMATION.................................................................. 6

1.3. GENERAL USE................................................................................................................. 7

1.4. DANGER SITUATIONS..................................................................................................... 7

1.5. SAFETY RULES IN THE INSTALLATION ............................................................................ 8

2. TECHNICAL DATA ................................................................................................................... 8

2.1. HEAT EXCHANGER ......................................................................................................... 8

3. INSTALLATION/ASSEMBLY ..................................................................................................... 8

3.1. TRANSPORTATION/STORAGE......................................................................................... 8

3.2. ASSEMBLY DIMENSIONS ................................................................................................ 8

3.3. INSTALLATION................................................................................................................ 9

3.4. HEAT EXCHANGER CONNECTIONS................................................................................. 9

3.5. HEAT EXCHANGER CONNECTION TO A FILTER/PUMP CIRCULATING SYSTEM............. 10

3.6. HEAT EXCHANGER CONNECTION TO A FILTER CIRCULATING SYSTEM ........................ 10

3.7. INSTALATION ............................................................................................................... 10

4. ELECTRICAL DIAGRAM ......................................................................................................... 11

5. START UP AND OPERATION ................................................................................................. 12

6. CONTROLLER ....................................................................................................................... 13

7. MAINTENANCE / FIXING ...................................................................................................... 17

7.1. HIBERNATION OF THE HEAT EXCHANGER IN FREE OF ICE SPACES.............................. 17

7.2. HIBERNATION OF THE HEAT EXCHANGER IN ICY SPACES ............................................ 17

7.3. Water-water heat exchanger in vertical position ........................................................ 17

7.4. Water-water heat exchanger in horizontal position.................................................... 17

8. TROUBLE SHOOTING ........................................................................................................... 17

9. EXPLODED VIEW .................................................................................................................. 18

10. PRODUCT RECYCLING ...................................................................................................... 20

11. WARRANTY CERTIFICATE ................................................................................................. 20

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

4

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

5

LISTA DE CONTENIDOS……….……………………………………..……ESPAÑOL

1. SEGURIDAD.......................................................................................................................... 22

1.1. Riesgos en el manejo del intercambiador de calor...................................................... 22

1.2. Instrucciones e información relativas a seguridad....................................................... 22

1.3. Uso general.................................................................................................................. 23

1.4. situaciones de peligro.................................................................................................. 23

1.5. Medidas de seguridad en el lugar de instalación......................................................... 24

2. DATOS TECNICOS................................................................................................................. 24

2.1. INTERCAMBIADOR DE CALOR ...................................................................................... 24

3. Instalación / Montaje........................................................................................................... 24

3.1. Transporte / Almacenamiento..................................................................................... 24

3.2. Medidas para el montaje y conexión........................................................................... 24

3.3. Instalación ................................................................................................................... 25

3.4. Conexión del intercambiador de calor......................................................................... 25

3.5. Conexión del intercambiador de calor a un sistema de circulación de filtro/bomba .. 26

3.6. Conexión del intercambiador de calor a un sistema de filtro ...................................... 26

3.7. INSTALACION ............................................................................................................... 26

4. Conexión ELECTRICA............................................................................................................ 27

5. PUESTA EN MARCHA / FUNCIONAMIENTO ......................................................................... 29

6. REGULADOR......................................................................................................................... 29

7. MANTENIMIENTO / REPARACIÓN........................................................................................ 33

7.1. Hibernación del intercambiador de calor en espacios libres de hielo ......................... 33

7.2. Hibernación del intercambiador de calor en espacios en donde haya hielo ............... 33

7.3. Intercambiador de calor en disposición vertical .......................................................... 33

7.4. Intercambiador de calor en disposición horizontal...................................................... 33

8. DETECCIÓN Y SOLUCIÓN DE AVERÍAS.................................................................................. 34

9. VISTA EXPLOSIONADA.......................................................................................................... 34

10. RECICLAJE DEL PRODUCTO .............................................................................................. 36

11. CERTIFICADO DE GARANTÍA ............................................................................................ 37

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

6

IT IS SUGGESTED THAT NOTE BE MADE OF THE FOLLOWING DATA

INSTALLER COMPANY

DATE

TELEPHONE

MODEL

SERIAL NUMBRE

DEALER`S STAMP

INSTALLER`S STAMP

1. SAFETY

1.1. HEAT EXCHANGER HANDLING RISKS

This equipment has been made using modern technology and following current safety good

practices. In spite of this, some risks could appear due to bad manipulations or uses. To avoid

that, the installer must follow the installation procedures that are included in this manual and use

this device for what was designed.

It is for your safety!

1.2. SAFETY INSTRUCTIONS AND INFORMATION

Next instructions relative to safety use next symbols:

It means direct health risk. If this information is not followed It could lead to

serious injuries

It means that it could lead to health risk. If this information is not followed It

could damage people health

It means that it could lead to health risk. If this information is not followed It

could lead to damage people or things

It means that this issue contains important information for using correctly the

device.

If this information is not followed the device or the enviroment could be

damaged.

DANGER

CARE

PRECAUTION

Please, read this manual carefully in order to: make a successful installation and start-up,

know the total potential of the machine, and take into account all the needed

circumstances for a proper and long-lasting performance.

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

7

1.3. GENERAL USE

The heat exchanger has been only designed to heat the pool water by means of a boiler.

The flow rate of water entering the heater must not exceed:

Heating element (MAIN) 10 bar máx.

Pool water (SECONDARY) 3 bar máx.

A higher flow rate will require the installation of a by-pass to prevent damage to the element(s).

¡Important!

A good use of this device it also means:

Follow all the information included in the installation instructions and, follow

inspection and maintenance instructions.

Any other application will not be considered as normal use. The manufacturer will not be then

responsible for any damage that it could appear.

Other uses could be only possible after the manufacturer’s agreement and approval.

Changes and adaptations are forbidden due to safety reasons.

1.4. DANGER SITUATIONS

The heater could lead to danger situations if:

Working pressure is higher than 3 bars for pool water and 10 bars for boiler.

Then leakages could appear with danger of burns.

Boiler side connections could reach 100ºC. The heater could reach this

temperature if it is not completely full of pool water.

Plastic piping could suffer thermal stresses that could lead to damage.

If the cycle it is not closed by means of a circulating/debugging puma, the

heater could reach the water boiler temperature and the exchanger could be

damaged.

If metal particles have entered into the internal heating coil it could appear

leakages due to rusting originated by contact and the boiler water could

contaminate the pool water.

PRECAUTION

CARE

PRECAUTION

PRECAUTION

PRECAUTION

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

8

1.5. SAFETY RULES IN THE INSTALLATION

Heat exchanger must be installed in a place free of frost.

Be sure that pressure is always lower than 3,0 bars in Secondary and 10 bars in the Primary.

The exchanger or the environment could be damaged.

2. TECHNICAL DATA

2.1. HEAT EXCHANGER

MODEL CODE

FEATURES

Capacity: kW

Boiler

Pool

90°C 60°C 45°C m3/h bar

m3/

h

Bar

WATERHEAT EQUIPADO 20kW

43506

20

10

5

1,6

0,14

10

0,14

WATERHEAT EQUIPADO 40kW

43507

40

20

10

2,7

0,45

15

0,24

WATERHEAT EQUIPADO 60kW

43508

60

30

15

3

0,78

20

0,29

Table 1: Technical data

3. INSTALLATION/ASSEMBLY

3.1. TRANSPORTATION/STORAGE

Transport the heat exchanger only after being drained.

Store the drained heat exchanger in indoor locations with a non aggressive atmosphere.

3.2. ASSEMBLY DIMENSIONS

MODEL CODE

DIMENSIONS (mm)

PACKAGING (mm)

WEIGHT

A

B

C

D

E

F

G

H

I

Long

Width

High

Kg

WATERHEAT

EQUIPADO 20kW

43506 530

456 160 215

1” 50 220 135

295

540 240 640 10

WATERHEAT

EQUIPADO 40kW

43507 530

590 160 225

1” 50 220 135

295

680 240 640 11

WATERHEAT

EQUIPADO 60kW

43508 530

650 160 305

1” 50 220 135

295

740 240 640 18

Check weekly that the exchanger and their connections are well tight and there

are not damages on them.

PRECAUTION

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

9

3.3. INSTALLATION

Install the heat exchanger only in areas with a non-aggressive atmosphere and free of frost. Any

drop on it could damage it.

A free access for install/des install must be granted.

The heat exchanger can be installed under/ or over the water level.

¡Important!

Meanwhile the boiling cycle is on; the heat exchanger never can be drained

from the water poolside.

3.4. HEAT EXCHANGER CONNECTIONS

Install the blocking and control units and the drain valves in the boiler cycle inlet and outlet pipes

internally free of frost.

Heat exchanger could be damaged due to water pressure.

Check the water quality and MAX pressure values in the lines.

Heat exchanger could be damaged when external cycle be connected. Check

that metal particles cannot reach the heat exchanger.

Brass connections between heat exchanger and steel pipes work as electrical

separators.

Heat exchanger could be damaged by chemical products.

Cleaning devices must be installed always after the heat exchanger. If chemical

products are used (for instance Cl ), avoid that gas enter into the heat

exchanger during the filtering stopping periods.

PRECAUTION

PRECAUTION

PRECAUTION

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

10

3.5. HEAT EXCHANGER CONNECTION TO A FILTER/PUMP CIRCULATING

SYSTEM

• Connect the boiler cycle to the primary heat exchanger.

• Connect the heat exchanger secondary to the pool piping’s by means of connections of tube

with tube clips or by means of inner spirals with connections of plastic/brass screw.

3.6. HEAT EXCHANGER CONNECTION TO A FILTER CIRCULATING

SYSTEM

• Connect both heat exchanger boiler elements to the water boiler cycle

• Connect the heat exchanger secondary to the pool piping by means of connections of tube with

tube clips or by means of inner spirals with connections of plastic/brass screw.

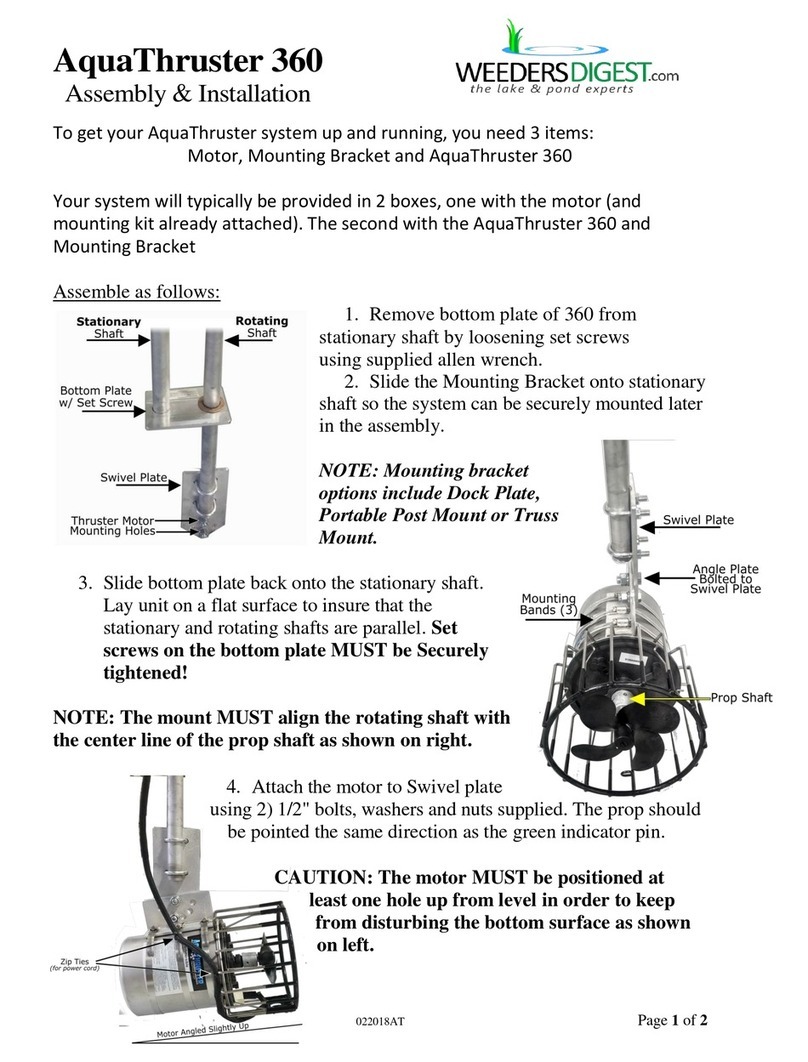

3.7. INSTALATION

•Hold the equipment through two M-6 blocks and M-4 clip, separated 220 mm. Hold the primary

and secondary pipes using clamps.

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

11

• Join the primary pipe using pipefittings and the secondary pipe using three-part-joints

(included). Power the equipment using the cable-glands at the bottom.

• Verify that there are no leaks and place the front cover.

4. ELECTRICAL DIAGRAM

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

12

5. START UP AND OPERATION

In the Titanium water-water heat exchanger the heat is transferred from the boiler cycle to the

pool water cycle.

ELECTRICAL DIAGRAM EQUIPPED WATERHEAT

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

13

The heat exchanger is made of titanium so it is suitable for water that contains a high amount of

Cl (as brine, therapeutic or of water of sea swimming pools).

A temperature probe can be added so that the pool water temperature can be controlled.

¿Have you read and understood these instructions, mainly the chapter of safety? Only if the

answer is yes the heat exchanger can be operated.

The water-water heat exchanger could be damaged if something drops on it.

Maintenance and fixing operations must be made only when both water cycle blocking units are

closed.

• Vent both water cycles

6. CONTROLLER

Main Function: the controller is a special controller for water-water heat exchangers, it contains

1 temperature sensor (water temperature) and 1 control output (filtering pump).

Temperature Display and Controlling: it can display water temperature and control the

temperature in water tank between the temperature upper and lower limit.

External alarm: one outside alarm input, it can be set to 5 modes: always open, always open

locked, always closed, always closed locked or forbidden.

Others: temperature upper and lower limit can be set; temperature sensor error alarm and so

on.

Main Technique Index:

- Temperature display range: -50/150°C (the step is 0.1°C)

- Temperature setting range: -45/145°C (the step is 0.1°C)

- Power supply: AC 220V±10% or AC 380V±10% 50Hz (refer to the wiring diagram)

- Operating environment: temperature -20Cº/50Cº, humidity 85%.

- Relay contact capability: 2 A / 380 V AC (pure resistive load)

- Temperature sensor: NTC R25=5k, B (25/50) =3470K

- Executive standard: Q/320585 XYK 01-2004 (NA8824-HTD)

Panel

PRECAUTION

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

14

What’s the meaning of the index lights on the panel?

The function of the LED on the panel is showing below:

INDEX LIGHT

NAME

LIGHT

FLASH

FILTRATION

PUMP

Equipment is heating, after the delay

of turning on the internal water

pump.

Filtration pump is on and the

equipment is timing for turning

on the internal water pump.

HEAT

Equipment is heating, after the delay

of turning on the internal water

pump.

- - -

ALARM - - - Alarm state.

The meaning of the LED display

The LED usually shows temperature, if it shows “SHr”, it means the temperature sensor is short,

and “OPE” means the temperature sensor is open. The temperature and the alarm code (Axx)

will show alternately when in the alarm state.

The code is showing below:

CODE

SIGNIFICATION

EXPLANATION

A11 External alarm

Alarm from external alarm signal, please refer to the

internal parameter code “F50”

A21

Water temperature

probe error

Disconnection or short circuit (showing “OPE” or

“SHr”.

A99 Over probation time

If you have set the probation time F87, the alarm

occurs when the accumulative running time is over

probation time and the controller cannot work.

How to set the temperature?

Press the key “set” for at least 2 seconds, then enter the state of temperature setting, here the

LED displays the setting temperature, then using “▲”key or “▼” key can change the

parameter (the key “▲” adds 0.1°C, the key “▼” minuses 0.1°C, press and hold it over 0.5

seconds can add or minus rapidly). After setting, press “set” again, then exit the state of

parameter setting. (The setting temp range is limited by the parameters F13 and F14; please

refer to the senior operation). Pressing the key “M” in the setting process means cancel and

exit, but the setting value will not be saved.

Advanced Operation

Press the key “M” and hold it for 5 seconds, and if you have set the password, the LED display

the “PAS” to hint you to enter the password, you can use the key “▲” and “▼” to enter the

password, if the password is correct, the LED will display the parameter code, use “▲” or “▼”

to select the parameter code. Pressing the “set” key can make it to show the value of the

parameter after select the parameter, here you use “▲” or “▼” to set the parameter(pressing

the key and not release can add or minus rapidly), then press the “set” key to return to the state

of showing parameter code after finishing setting. Pressing the key “M” can exit the parameter

setting state when display the parameter code, pressing the key “M” means cancel when in the

process of setting parameter, and the parameter will not be changed.

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

15

Internal parameter code is showing below:

SORT CODE PARAMETER NAME RANGE

FACTORY

SETTING

UNIT REMARKS

TEMPERATURE

F11 Setting temperature F14F13 28 ºC / ºF

The setting range is limited by

F13 and F14.

F12 Differential temp. 0,120 1,0 ºC / ºF

Refer to the temperature

controlling.

F13

Max temperature

setting

-58302 35 ºC / ºF

Controller will follow the rule:

F14<F11<F13. If one parameter

cannot be adjusted is because it

is limited by another parameter.

F14

Min temperature

setting

-58302 10 ºC / ºF

F18

---

---

---

---

---

F19

Temp probe

adjustment

-2020 0.0 ºC / ºF Adjusts probe temperature.

WATER PUMP

F21

Water pump delay

010

3

min

F29

---

---

---

---

---

---

F31

---

---

---

---

---

F32

---

---

---

---

---

F33

---

---

---

---

---

F34

---

---

---

---

---

FILTRATION

F40

---

---

1

---

---

F41

Filtration starts time

before water pump

110 3 min

F42

Filtration stop time

after water pump

010 3 min

ALARM

F50 External alarm mode 0 to 4 0 ---

0:without external alarm

1:always open, unlocked

2:always open, locked

3:always closed, unlocked

4:always closed, locked

F59 Buzzer alarm sound

duration

off – 0,1

1,0 - on 0,5 min

Off: No alarm sound

On: Alarm sound always on until

pressing a key

---

F60

---

---

---

---

---

F61

---

---

---

---

---

F62

---

---

---

---

---

F63

---

---

---

---

---

F64

---

---

---

---

---

F65

---

---

---

---

---

F66

---

---

---

---

---

F69

---

---

---

---

---

SYSTEM SETTING

F80 Password

off – 0001

9999

off ---

Off: no password

0000: means clearing password

F81 Temperature units ºC / ºF ºC ---

ºC: Centrigrade

ºF: Fahrenheit

F85

Display accumulative

running time

--- --- hour

F86

Accumulative running

time reset

--- --- ---

F87 Probation time off – 0001

9999 off hour

The controller will stop if the

accumulative time is over

probation time and show the

alarm code “A99”

Off means no probation time

TESTING

F98

Reserved

---

---

---

---

F99 Set test

This function can attract all relays in turn; please do not use when the

controller is running.

END

exit

Basic Operating Principle

Temperature controlling

The controller has a temperature controlling mode.

Temperature controlling point is controlled by “setting temperature (F11, or press the “set” key

for some time to set and temperature difference “(F12)”.

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

16

While heating, the controller begins to heat when the temperature of the temperature sensor is

under “setting temperature – differential temperature”, and it stops heating when the

temperature is over “setting temperature + differential temperature”

Water pump delay time

The water pump delay time is set by F21, for example, 3 minutes. The controller contains a

“water pump halt calculagraph”, and it begins to time when water pump stops, the program

first check the calculagraph before booting the water pump next time, the program will

immediately boot the water pump if the calculagraph reach 3 minutes.

If the calculagraph doesn’t reach 3 minutes, it will boot again when the calculagraph reaches 3

minutes. Thus you can ensure that the boot alternation is over 3 minutes after halt, so it can

prevent to breaking the water pump as a result of frequent boot. In addition, the controller

doesn’t boot the water pump within 3 minutes after turning on the power supply, thus the

water pump can also be protected in the state of power cut and then power on.

External alarm

The controller can connect a switching value as external alarm source (Pin 4, 5), when the

external alarm occurs, the controller stops, displays

The alarm code “A11” and generates alarm output. External alarm signal has 5 modes (F50):

· 0: without external alarm

· 1: always open, unlocked

· 2: always open, locked

· 3: always closed, unlocked

· 4: always closed, locked

“Always open” means in normal state, external alarm signal is open, if closed, the controller will

give an alarm; “Always closed” is on the contrary. “Locked” means that when external alarm

signal becomes normal, the controller is still in the alarm state, and it needs to press any key to

resume.

Probation time

A probation time can be set (F87), the controller can add up the running time after power is on,

if the accumulative running time is over the probation time, the controller will stop and display

the alarm code A99, if you want to eliminate the limit of probation time, set the F87 to “OFF”,

also you can use the F86 to clear the accumulative running time, and you can try to use it again.

The parameter F85 can be used to examine the accumulative running time of the controller

(hour).

Password

In order to prevent irrespective persons from changing the parameters, you can set a password

(F80), and if you have set a password, the controller will hint you to enter the password after

you press the key “M” for 5 seconds, you must enter the correct password, and then you can

set the parameters. If you don’t need the password, you can set F80 to “OFF”. Notice that you

must remember the password, and if you forget the password, you cannot enter the set state.

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

17

7. MAINTENANCE / FIXING

• Check that the connections are tight once per week.

7.1. HIBERNATION OF THE HEAT EXCHANGER IN FREE OF ICE SPACES

Non-qualified personnel working on the technical systems could lead to injuries

or damages.

For its hibernation in free ice spaces the water-water heat exchanger must be

completely full of water.

7.2. HIBERNATION OF THE HEAT EXCHANGER IN ICY SPACES

Hibernation free of ice it is possible if next steps are followed:

• Close blocking units in both water cycles.

• Empty the exchanger and the pipes until the blocking units.

7.3. Water-water heat exchanger in vertical position

• Empty the heat exchanger through the drain completely.

7.4. Water-water heat exchanger in horizontal position

• Remove the water-water heat exchanger.

• Drain the heat exchanger and keep it in dry storage.

8. TROUBLE SHOOTING

Effect Check

It does not work ¿Blocking units are open?

¿Water-water heat exchanger is completely full in both

cycles?

¿ Water-water heat exchanger was vented?

¿Is there sufficient water flow (check technical data)?

PRECAUTION

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

18

9. EXPLODED VIEW

PART

Nº

MODEL

CODE

1

Exchanger Waterheat 20 kw

EQUIP. WATERHEAT 20KW

41426

1

Exchanger Waterheat 40 kw

EQUIP. WATERHEAT 40KW

41427

1

Exchanger Waterheat 60 kw

EQUIP. WATERHEAT 60KW

41428

2

Set Joins Closing 20 kw

EQUIP. WATERHEAT 20KW

43506R0001

2

Set Joins Closing 40 kw

EQUIP. WATERHEAT 40KW

43507R0001

2

Set Joins Closing 60 kw

EQUIP. WATERHEAT 60KW

43508R0001

3

Link 3 Pieces

EQUIP. WATERHEAT 20-40-60KW

43506R0002

4

Power supply hose

EQUIP. WATERHEAT 20-40-60KW

43506R0003

5

Cable Glands

EQUIP. WATERHEAT 20-40-60KW

43506R0004

6

Lateral Enclosure ABS

EQUIP. WATERHEAT 20-40-60KW

43506R0005

7

Check Valve 3/4"

EQUIP. WATERHEAT 20-40-60KW

43506R0006

8

Rear Enclosure 20 kw

EQUIP. WATERHEAT 20KW

43506R0007

8

Rear Enclosure 40 kw

EQUIP. WATERHEAT 40KW

43507R0002

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

19

8

Rear Enclosure 60 kw

EQUIP. WATERHEAT 60KW

43508R0002

9

Plexo Box d-70mm

EQUIP. WATERHEAT 20-40-60KW

43506R0008

10

Clema 10

EQUIP. WATERHEAT 20-40-60KW

43506R0009

11

Recirculation Pump

EQUIP. WATERHEAT 20KW

43506R0010

11

Recirculation Pump

EQUIP. WATERHEAT 40KW

43507R0003

11

Recirculation Pump

EQUIP. WATERHEAT 60KW

43508R0003

12

Tª Sensor

EQUIP. WATERHEAT 20-40-60KW

43506R0011

13

Front Enclosure 20 kw

EQUIP. WATERHEAT 20KW

43506R0012

13

Front Enclosure 40 kw

EQUIP. WATERHEAT 40KW

43507R0004

13

Front Enclosure 60kw

EQUIP. WATERHEAT 60KW

43508R0004

14

Thermostat

EQUIP. WATERHEAT 20-40-60KW

43506R0014

15

Cable Glands

EQUIP. WATERHEAT 20-40-60KW

43506R0015

16

Resistance

EQUIP. WATERHEAT 20-40-60KW

43506R0016

WATERHEAT SERIES · WATER/WATER SYSTEM

© ASTRALPOOL 2018 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

ENGLISH

20

10. PRODUCT RECYCLING

This water-water heat exchanger in made of stainless steel an Titanium. When it

reaches the end of its service life, it should be dismantled by an authorised company or may be

transported to the place assigned by the corresponding local authorities.

With the aim of reducing the amount residues and the danger of their components, to promote

the recycling of the equipment and the appreciation of their residues, and to determine a suitable

management that attempts to improve the effectiveness of the environmental protection, a

series of regulations applicable to the manufacturing of the product and others related to the

correct environmental management when they become residues have been implemented.

As of 13 August 2005, when you wish to throw away this unit, you have two possible return

systems:

- If you acquire a new one that is of an equivalent type or it has the same functions as the one

thrown away, you could hand it over at no cost to the distributor.

- Or you could take it to the place so selected by the local authorities.

The units are labelled with the symbol of a “crossed out wheeled rubbish container”. This symbol

denotes the need for its selective and differentiated collection from the rest of urban rubbish.

Possible effects over the environment or human health of the dangerous materials it may

contain.

TITANIUM

Health effects. Elemental titanium and titanium dioxide are of low order of toxicity. Humans

overexposed to titanium dioxide via inhalation can develop sight changes in lungs.

Effects of overexposure to titanium powder. Dust inhalation may cause tightness and pain in

chest, coughing, and difficulty in breathing. Contact with skin or eyes may cause irritation.

Routes of entry: Inhalation, skin contact, eye contact.

Carcinogenicity. The International Agency for Research on Cancer (IARC) has listed titanium

dioxide within Group (The agent is not classifiable as to its carcinogenicity to humans).

Environmental effects. Low toxicity. No negative environmental effects of titanium have been

reported.

11. WARRANTY CERTIFICATE

This manual suits for next models

2

Table of contents

Languages:

Popular Industrial Equipment manuals by other brands

beneq

beneq TFS 200 operation instruction

Nidec

Nidec LEROY-SOMER LSAH 44.3 Installation and Maintenance

Waterous

Waterous K Series Operation and maintenance instruction

SAMES KREMLIN

SAMES KREMLIN Cyclomix Evo instruction manual

Tisch Environmental

Tisch Environmental TE-5170DV-BL Operation manual

ABB

ABB Power2 550-M44 Operation manual