Product Type:Model: PRN2 1/2" CAPACITY AUTOMATIC RIVET NUT

SETTING KIT - METRIC & SAE

Page 1

Study, understand and follow all instructions provided

with this product. Read these instructions carefully

before installing, operating, servicing or repairing this

tool. Keep these instructions in a safe accessible place.

INTENDED USE OF THE TOOL

This tool intended to be used to set M5-M12 and

10-24"-1/2" aluminum and steel rivet nuts. Operate only

at the require air pressure necessary. Do not over-set

rivet nuts. Do not use this tool outside of the designed

intent. Never modify the tool for any other purpose or use.

Caution: To help prevent personal injury

• Use of this product can expose you to chemicals

such as phthalates which are known to the State

of California to cause cancer, and birth defects or

other reproductive harm. For more information go

to www.P65Warnings.ca.gov/product.

Always wear ANSI approved safety equipment,

safety glasses and clothing when using this

product. Study, understand, and follow all

instructions provided with this product. Failure to

read and follow all warnings and operating

instructions may result in damages and serious

injury or death.

• Always wear ANSI approved goggles when using

this product. (Users and By standers).

• Never use this tool for any application other than for

which it was designed.

• Only use accessories designed for this tool.

• Never alter or modify this tool in any way.

• Improper operation and/or maintenance of the tool,

modification of the tool, or use of the tool with

accessories not designed for it could result in

serious injury or death.

• Always select the correct accessories of the correct

size and design for the job that you are attempting to

perform.

• Always work in a clean, safe, well-lit, organized and

adequately equipped area.

• Do not begin repairs without assurance that vehicle

is in secure position, and will not move during repair.

WARNING

WARNING

www.astrotools.com

1 YEAR LIMITED WARRANTY

PLEASE DO NOT RETURN ANY PRODUCT WITHOUT CALLING

1-800-221-9705 FOR INSTRUCTIONS

PRODUCT INFORMATION

BEFORE USE

DO NOT DISCARD – GIVE TO USER

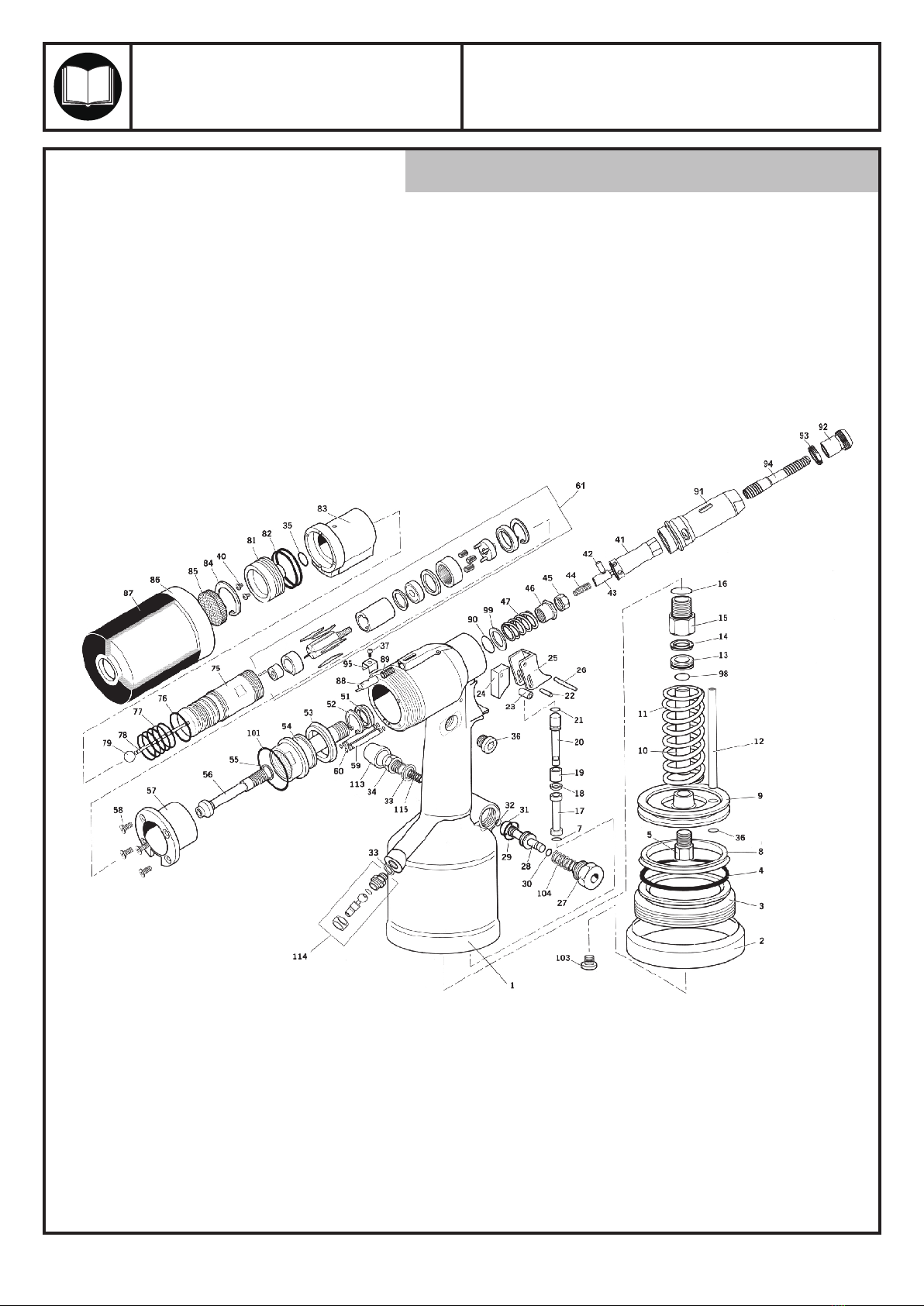

When unpacking, check the parts diagram and part

number listing on page 5 to make sure all parts are

included. If any parts are missing or damaged,

please call your distributor.

• Astro Pneumatic Tool Co. warrants our products to the original user

against defective material or workmanship for a period of 1 year

(except where noted on our price schedule) from the date of 1st use.

Astro reserves the right to determine whether the product failed

because of defective material, workmanship or other causes and to

charge back for missing parts. Astro Pneumatic Tool Co., at its

discretion, will repair products covered under this warranty free of

charge. The distributor should direct the original user to return the

product (with the exceptions listed below) with the distributor’s

name, address, adequate proof of date of purchase or a copy of

warranty card, and a short note explaining the problem. Failures

caused by accident, alteration, or misuse are not covered by

this warranty.

• If one part of this product fails, please do not return the entire

product. Astro will replace free of charge component parts of

this product that fail within 1 year of first use by the original

user. Items included in this category include but are not limited

to kits, hand tool kits and any other product where there are

multiple items or components that make up the unit. Please

contact the phone number below in order to obtain the

replacement components covered under warranty.

• Astro Pneumatic Tool Co. or its authorized service representatives

must perform all warranty repairs. Any repair to the product by

unauthorized service representatives voids this warranty. The rights

under this warranty are limited to the original user and may not be

transferred to subsequent owners.

• This warranty is in lieu of all other warranties, expressed or implied,

including warranties of merchantability and fitness for a particular

purpose. Some states do not allow the exclusion of limitations of

incidental or consequential damages so the above limitations may

not apply to you.

• Fully automated operation. One pull of the trigger

sets and unthreads the tool from rivet nuts up to

M12 and 1/2"

• Includes 10 mandrels / nosepieces in the following sizes:

M5, M6, M8, M10, M12, 10-24, 1/4", 5/16", 3/8", 1/2"

• 4270 lbs of instant air-hydraulic pulling force

• Up to 7mm of adjustable stroke length, set by rotating

the rear drum to your desired stroke setting

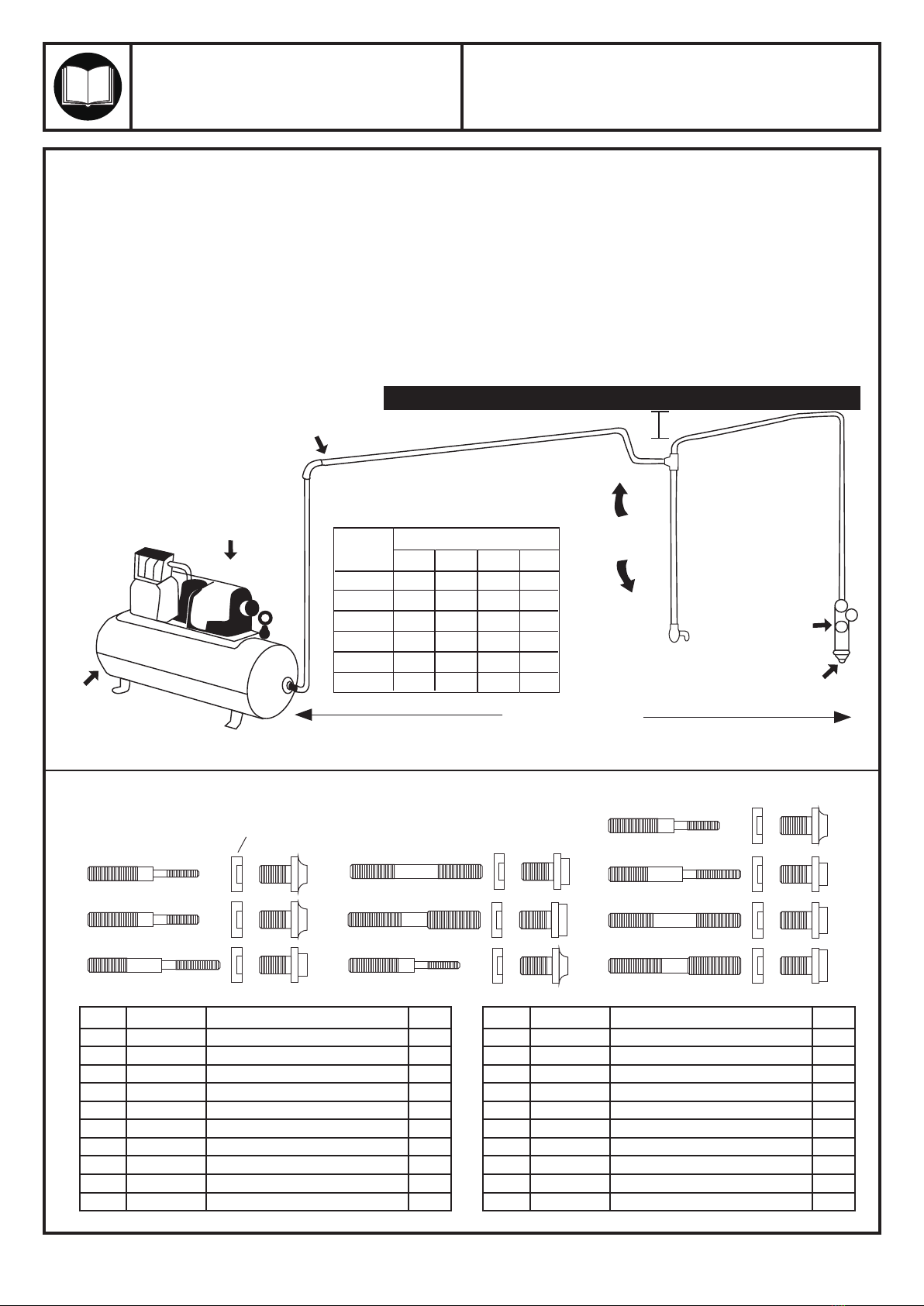

Traction Power:

Tool Stroke:

Work Capacity:

Air Inlet:

4270 lbs of force

7mm max

1/2"

1/4" PT

Specification: