Chint Solar (Zhejiang) Co.,Ltd. | Add:1335 Bin´an Road, Binjiang District, Hangzhou | P.C: 310053

Tel: 0086-571-5603 1888 | Fax: 086-571-5603 2316 | Website: http://energy.chint.com/

2.2.8 Do not work alone.

2.2.9 Wear a safety harness if working far above the ground.

2.2.10 Do not wear metallic jewelry, which can cause electric shock, while installing or

troubleshooting the PV system.

2.2.11 Follow the safety regulations for any and all other system components, including wires,

connectors, charging regulators, batteries, inverters, etc.

2.2.12 Do not expose wires to direct sunlight. Use UV-resistant cable.

2.2.13 Do not damage the surrounding PV modules or mounting structure when replacing a PV

module.

2.2.14 Do not change any PV module components (diode, junction box, connectors, etc.).

2.2.15 The maximum reverse current is 20.25A for module with Isc≤9.61A and 27A for module

with Isc>9.61A. Application of the blocking diode and fuse in the combiner box are

recommended for reverse current protection when more than two strings are connected in

parallel.

2.2.16 A certain gap is maintained between the PV module and the mounting surface to prevent

the mounting surface touching the junction box.

2.2.17 Standing on the solar PV module is forbidden and also prohibit installation tools or other

objects hitting surface of the solar PV module.

2.2.18 The solar modules are recommended to be installed over a fireproof and insulating roof

covering when installed on a roof.

2.2.19 PV cable connection cannot be too tight, it is recommended that the connector and the

backsheet have a certain gap.

2.2.20 In sandy regions, in order to avoid getting sand into the connector, we suggest to short

circuit module connectors before installation. If grains of sand get into the connectors it,

may cause internal live parts wear and tear and affect electrical safety.

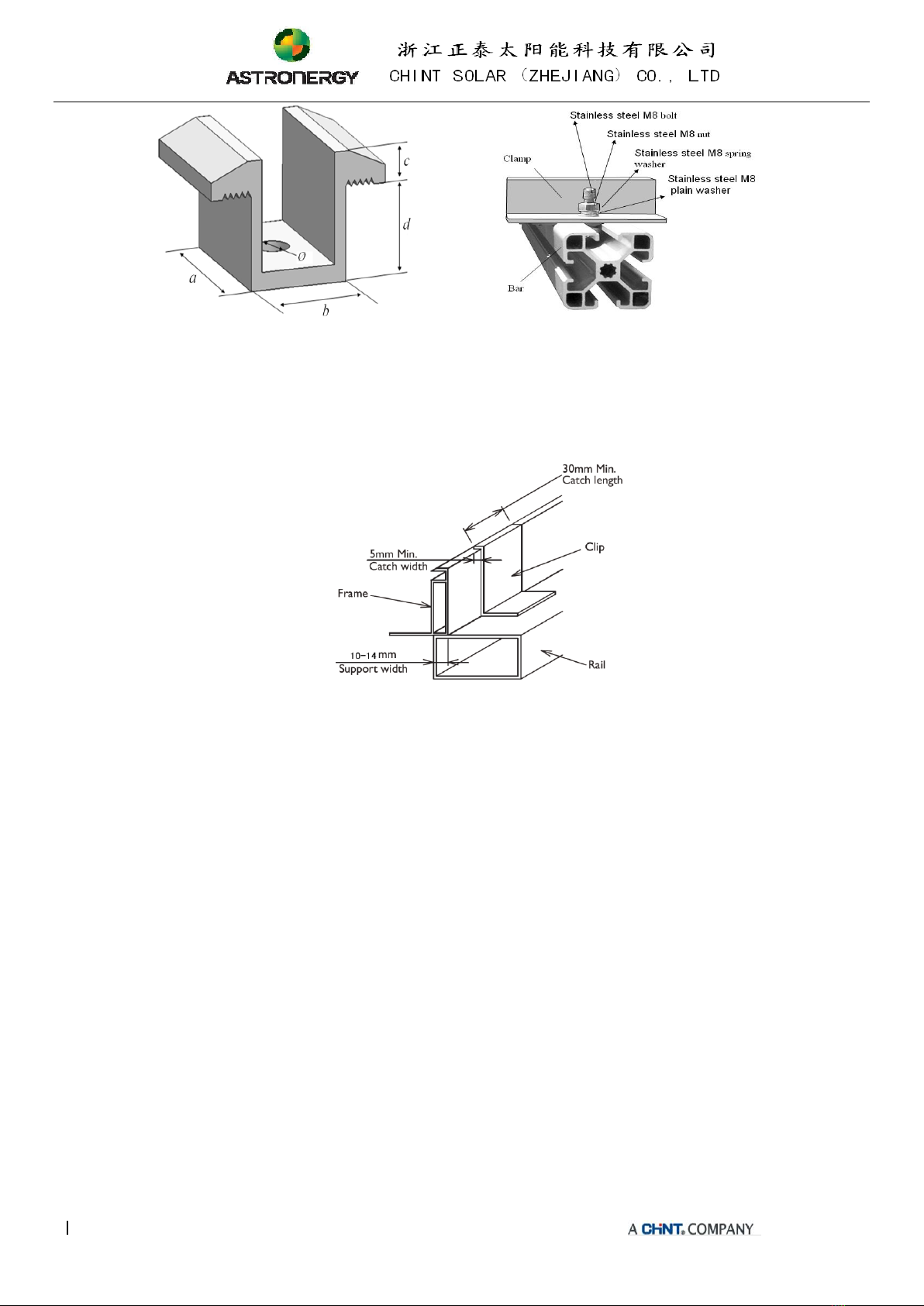

3 Mechanical Installation

3.1 Installation Conditions

3.1.1 Extreme environment temperature:-40℃to +85℃

3.1.2 Operating temperature:-40℃to +85℃

3.1.3 Please refer to the detailed mounting instructions as Chapter 3.2.

3.1.4 Tilt Angle selection: The installation should be facing north in the southern hemisphere

and facing south in the northern hemisphere.

3.1.5 To maintain the modules’ Class C fire rating, the fire class of the roof and building

materials should be higher than Class C.

3.1.6 To maintain the modules’ fire performance type 1(for US market), it could be possible to

achieve the Class A system fire rating, with a Class A class racking system.