Solon Black 160/05 Instruction manual

Table of contents

Other Solon Solar Panel manuals

Popular Solar Panel manuals by other brands

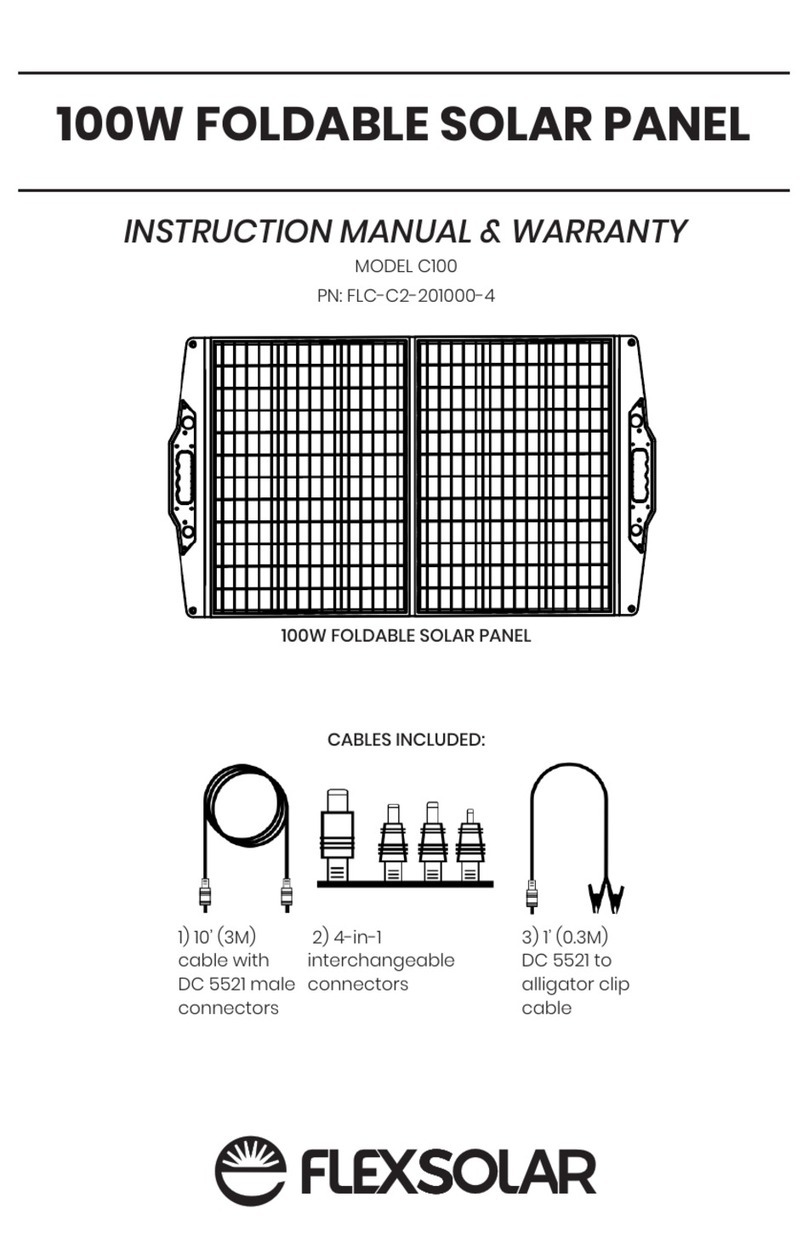

Flexsolar

Flexsolar C100 Instruction manual & warranty

Solar Technology International

Solar Technology International PV Logic MHD Flexi user manual

Sonnenkraft

Sonnenkraft SS20 manual

SolarPath

SolarPath SPSF Series installation manual

DeDietrich

DeDietrich PRO C250V installation manual

Immergas

Immergas BASIC SOL V2 Instruction booklet and warning

Kyocera

Kyocera KD100 P Series datasheet

Ariston Thermo

Ariston Thermo XP 2.5-1 instruction manual

Haier

Haier PGT2.0-2 installation manual

Qcells

Qcells Q.POWER-G5.1 Installation and operation manual

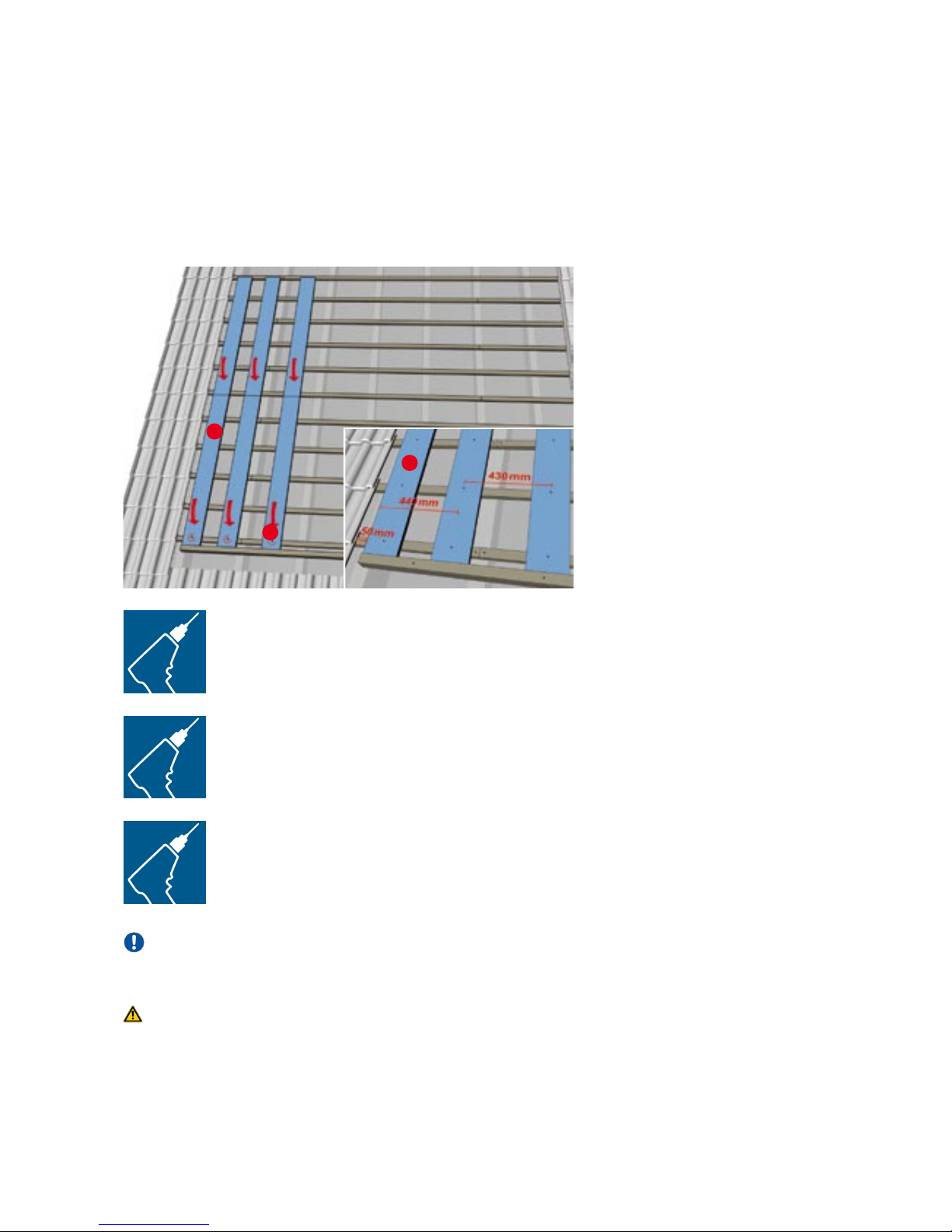

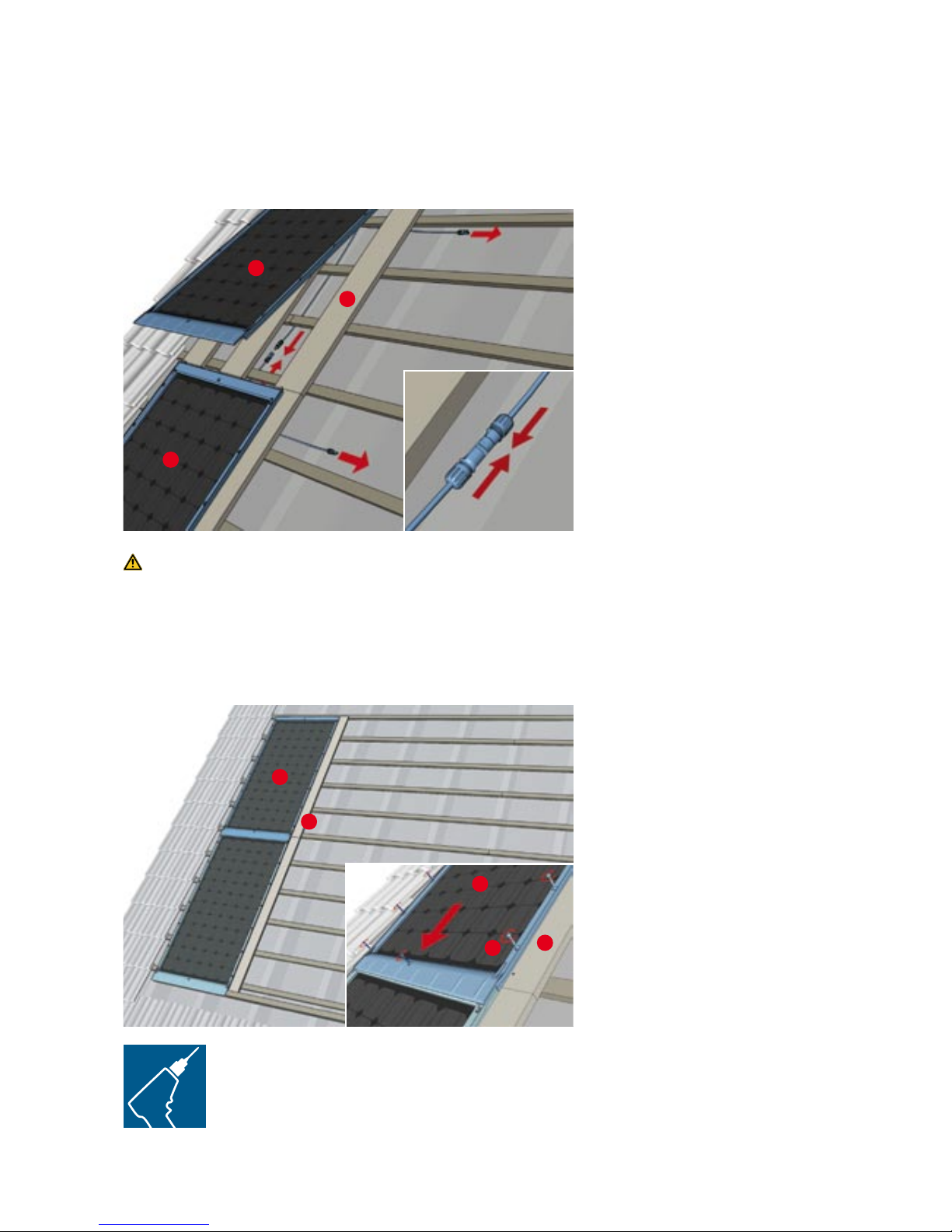

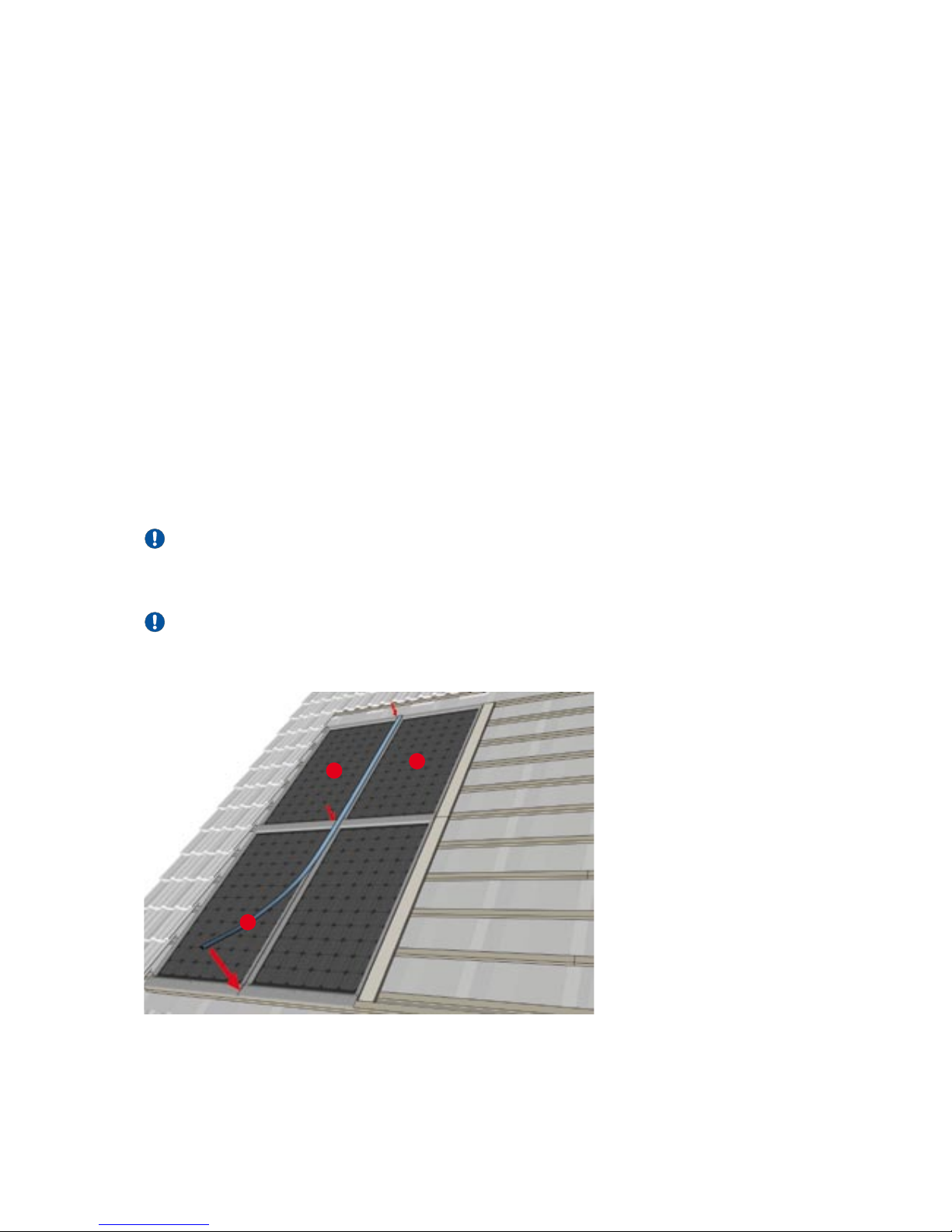

ESDEC

ESDEC CLICKFIT BASIC manual

Solar Technology International

Solar Technology International PV Logic user manual

Kyocera

Kyocera KD MODULES brochure

Beretta

Beretta SCV-25 installation manual

SUNPRO

SUNPRO SP410-108M10 installation manual

Solar Technology International

Solar Technology International PV Logic STP005 user manual

LG

LG PV Solar MODULE installation manual

Solglass

Solglass Solartrix 1200-400 Series installation manual