ADJUSTMENT AND MAINTENANCE

GENERAL INFORMATION

AH adjustments are thoroughly checked and corrected when the

monitor leaves the factory. Therefore the monitor should operate

normally and produce proper color and pictures upon installa-

tion. However, serveral minor adjustments may be required

depending on the particular location in which the monitor is to

operate. This monitor is shipped completely in cardboard car-

ton. Carefully draw out the monitor from the carton and remove

all packing materials. Plug the power cord into aconvenient 220

volts 50 Hz AC power outlet. Never connect to direct current

or any other power outlet or frequency. Check and adjust all the

customer controls such as BRIGHTNESS, and CONTRAST to

obtain anormal picture,

AUTOMATIC DEGAUSSING

Adegaussing coil is mounted around the picture tube so that ex-

ternal degaussing is normally unnecessary after moving the

monitor. The monitor should be properly degaussed upon in-

stallation. The degaussing coil operates for about 1second after

the power to the monitor is switched ON. If the set is moved

or faced in adifferent direction, the power switch must be swit-

ched off for at least 10 minutes in order that the automatic

degaussing circuit operates properly.

Should the chassis or parts of the cabinet become magnetized to

cause poor color purity, use an external degaussing coil. Slowly

move the degaussing coil around the faceplate of the picture tube,

the sides and front of the monitor, and slowly withdraw the coil

to adistance of about 2meters before disconnecting it from the

AC source. If color shading still persists, perform the CON-

VERGENCE ADJUSTMENT procedures, as mentioned later.

HIGH VOLTAGE CHECK

WARNING: There is no HIGH VOLTAGE ADJUSTMENT

on this chassis. The +115 volt power supply must

be properly adjusted to insure the correct high

voltage.

1. Connect an accurate high voltage meter to the second

anode of the display tube.

2. Turn on the monitor. Set the BRIGHTNESS and CONTRAST

controls to monimum (zero beam current).

3. High voltage will be measured below 24.0 KV.

4. Rotate the BRIGHTNESS control to both extremes to be sure

that the high voltage does not exceed the limit of 24.5 KV

under any conditions.

FS CIRCUIT CHECK (Hold Down)

The FS (fail safe) circuit check is indispensable for the final check.

Checking should be done following steps:

1. Turn the power switch ON and adjust customer controls for

normal operation.

2. Connect aVTVM between (the cathode of D704) and the

chassis ground.

3. Adjust brightness, and contrast, for mechanical minimum.

4. Adjust the Hold-down VR (R725) on the main board for the

voltage of (the cathode voltage of D704) in DC10.25V.

5. After adjusting the voltage, fix the hold down VR (R725) with

EPOXY or same kind of bond.

6. Check the set in the hold down when the voltage of TP5 (the

cathode voltage of D704) is 13.2V +0.5, —0V.

7. If this monitor is not the FS (fail safe), repeat steps 1through 5.

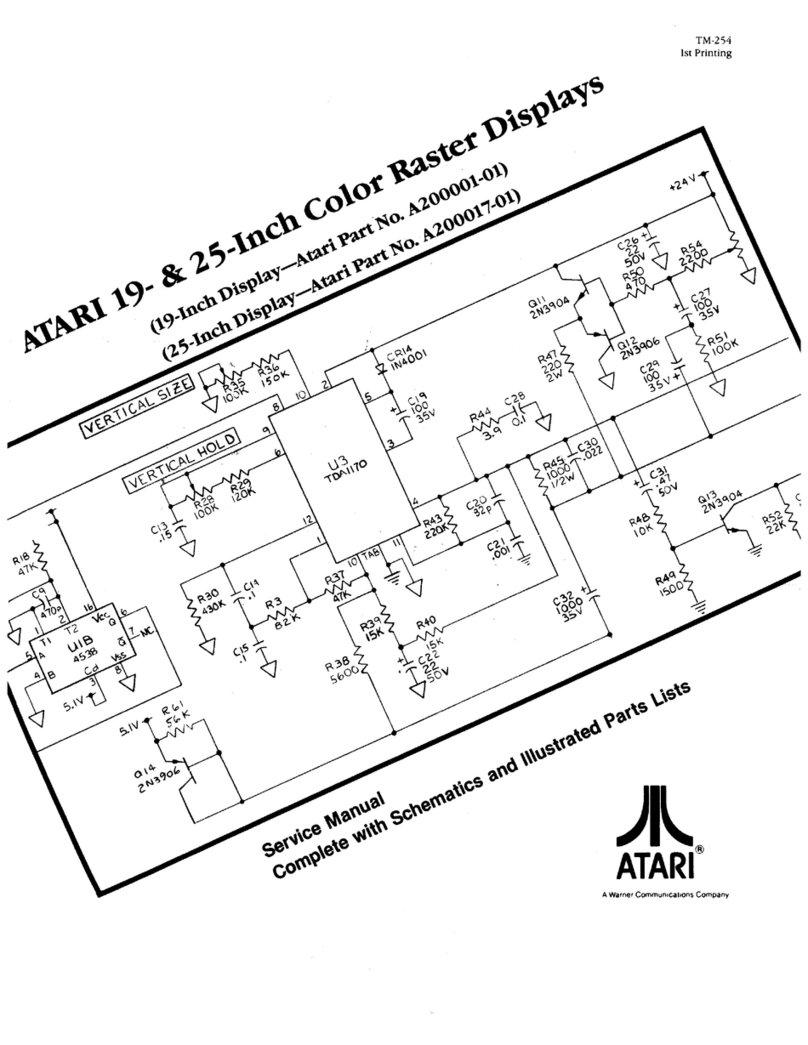

HORIZONTAL OSCILLATOR ADJUSTMENT

If there is an indication of unstable horizontal sync., adjust the

HORIZONTAL HOLD control (R716) until screen image is stable.

VERTICAL OSCILLATOR ADJUSTMENT

If the picture moves up or down on the screen, adjust the VER-

TICAL HOLD control (R603) at the back of the monitor until

there is asingle image without vertical movement.

VERTICAL SIZE ADJUSTMENT

The vertical size control (R616) on the main board changes the

size of the picture or pattern, having an equal effect on the top

and bottom. The final adjustment for the V-size of picture is 150

mm for 12".

FOCUS ADJUSTMENT

Adjust the FOCUS control on the focus pack for well defined

scanning lines in the 1/4 and 3/4 points of the screen.

HORIZONTAL WIDTH ADJUSTMENT

Adjust the horizontal width control coil (L702) by turning it with

a hexagonal adjusting tool so that the width of the picture (data

display area) is 210 mm for 12".

H-POSITION ADJUSTMENT

Adjust the H-position control (R710), so that the center of pic-

ture is the same as the mechanical center of the screen.

V-LINEARITY ADJUSTMENT

1. Display the cross hatch with the character generator.

2. Adjust R635 (V-LIN.) to the best condition.

3. Non-Linearity should be within ±7%.

4. If V-size is changed after adjusting R635 (V-LIN.), readjust

R616 (V-SIZE). At the time, signal is reverse pattern.

SUB-BRIGHTNESS ADJUSTMENT

1. Supply white color with acomputer to the video input

terminal.

2. Turn the contrast to the maximum with the contrast volume

(fully clockwise) and BRIGHTNESS to the minimum with the

bright volume (fully counterclockwise).

3. Adjust the sub-bright volume (R742) to cut-off the picture

slightly.

.. VERTICAL CENTER ADJUSTMENT

Adjust the V-center control (R626), so that the center of the pic-

ture is the same as the mechanical center of the screen.

SIDE PCC ADJUSTMENT

1. Display the reverse pattern with the character generator.

2. Adjust to minimum by rotating R621 (side PCC).

3. At this time, the pincushion or barrel distortion should be

within 1.5% (max.)

WHITE BALANCE ADJUSTMENT

1. EQUIPMENT

•Video Signal generator: LVG-1600 (Analog input)

R: lVp-p G: lVp-p B: lVp-p

•Oscillascope

•W/B meter

•Color analyzer

2. Adjustment 1

•Input the 16 step wave 4 Pattern) to the set.

•Set the BRIGHTNESS, CONTRAST VOL to the maximum.

•Set the Video output level (R511 rear part) 45Vp-p with ad-

justing the G. DRIVE (R303).

•Set the Video output level (R510 rear part) 45Vp-p with ad-

justing the R.DRIVE (R323.)

•Adjust R.LEVEL (R369) in order to agree with Rand G.

output level when CONTRAST is minimum position.

•Adjust the R.DRIVE again in order to agree with Rand G.

output level when CONTRAST is maximum.

•When CONTRAST is maximum or minimum. As above

(4) (5) (6) adjust the B.DRIVE (R343) in order to agree with

Band G. OUTPUT Level.

3. Adjustment 2

•Set the SCREEN, CONTROL BRIGHTNESS, CONTRAST

VOL.

•Set the SUB BRIGHT (R742) to the maximum.

•Set the R.CUT OFF (R317). G. CUT OFF (R337) B. CUT

OFF (R357) to the center position.

•Input the reverse pattern.

•Set the reverse pattern 3FL in the COLOR ANALYZER with

rotating the SCREEN CONTROL.

•In the case, adjust R.G.B CUT OFF (R317, R337, R357) As

below X.Y with W/B METER.

X: 0.28 ±0.002 =0.279 -0.283

Y: 0.311 ±0.002 =0.309-0.313

4. Adjustment 3

Set the CONTRAST AND BRIGHTNESS VOL to the max-

imum. Set the reverse pattern 28FL in the COLOR

ANALYZER with rotating the SUB-BRIGHT (R742).

CONVERGENCE ADJUSTMENT

NOTE: Before attempting any convergence adjustments, the

monitor should be operated for at least fifteen minutes.

•Center Convergence Adjustment

1. Supply acrosshatch pattern with a color character generator.

to the video input.

2. Adjust the brightness and contrast controls for awell defined

pattern.

3. Adjust the two tabs of the 4-pole magnets to change the angle

between them (See Figure 3) and superimpose red and blue

vertical lines in the center area of the picture screen. (See Figure

4).

4. Turn both the tabs at the same keeping the angle constant to

superimpose red and blue horizontal lines at the center of the

screen. (See Figure 4)

5. Adjust the two tabs of the 6-pole magnets to superimpose

red/blue line and agreen one. Adjusting the angle affects the

vertical lines, and rotating both magnets affects the horizon-

tal lines.

6. Repeat adjustment steps 3,4,5 describing red, green and blue

movements. The 4-pole magnets and the 6-pole magnets have

mutual affection making dots movement complex.

•Circumference Convergence Adjustment

1. Loosen the clamping screw of deflection yoke to allow the yoke

to tilt.

2. Put awedge temporarily, as shown in Figure 2. (Do not

remove the cover paper on the adhesive part of the wedge.

)

3. Tilt front of the deflection yoke up or down to obtain better

convergence in circumference. (See Figure 2) push the mounted

wedge into the space between display tube and the yoke to

fix the yoke temporarily).

4. Put the other wedge into the bottom space and remove the

cover paper.

5. Tilt the front of the yoke right or left to obtain better con-

vergence in circumference. (See Figure 2).

6. Keep the yoke position and put another wedge in eighter up-

per space. Remove the cover paper and stick the wedge on

the display tube to fix the yoke.

7. Detach the temporarily mounted wedge and put it in another

upper space. Stick it on the display tube to fix the yoke.

8. After attaching three wedges, recheck overall convergence.

Tighten the screw firmly to fix the yoke and check the yoke

is firm.

9. Stick 3 adhesive tapes on the wecjges as shown in Figure 2.

-6--7-