ATD Tools ATD-7461A Service manual

Other ATD Tools Lifting System manuals

ATD Tools

ATD Tools 4P9DXL Operating instructions

ATD Tools

ATD Tools ATD2P11BS User manual

ATD Tools

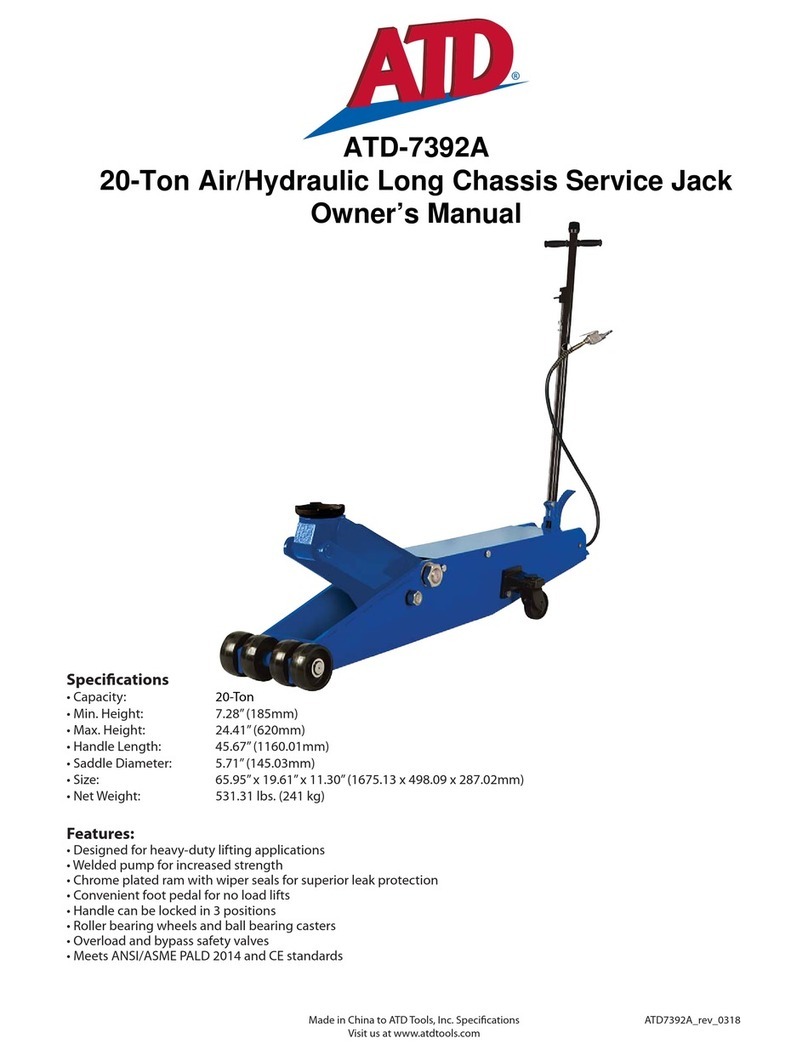

ATD Tools 7392A User manual

ATD Tools

ATD Tools ATD4P8D Operating instructions

ATD Tools

ATD Tools 6557 User manual

ATD Tools

ATD Tools ATD-10141A User manual

ATD Tools

ATD Tools ATD-7425A User manual

ATD Tools

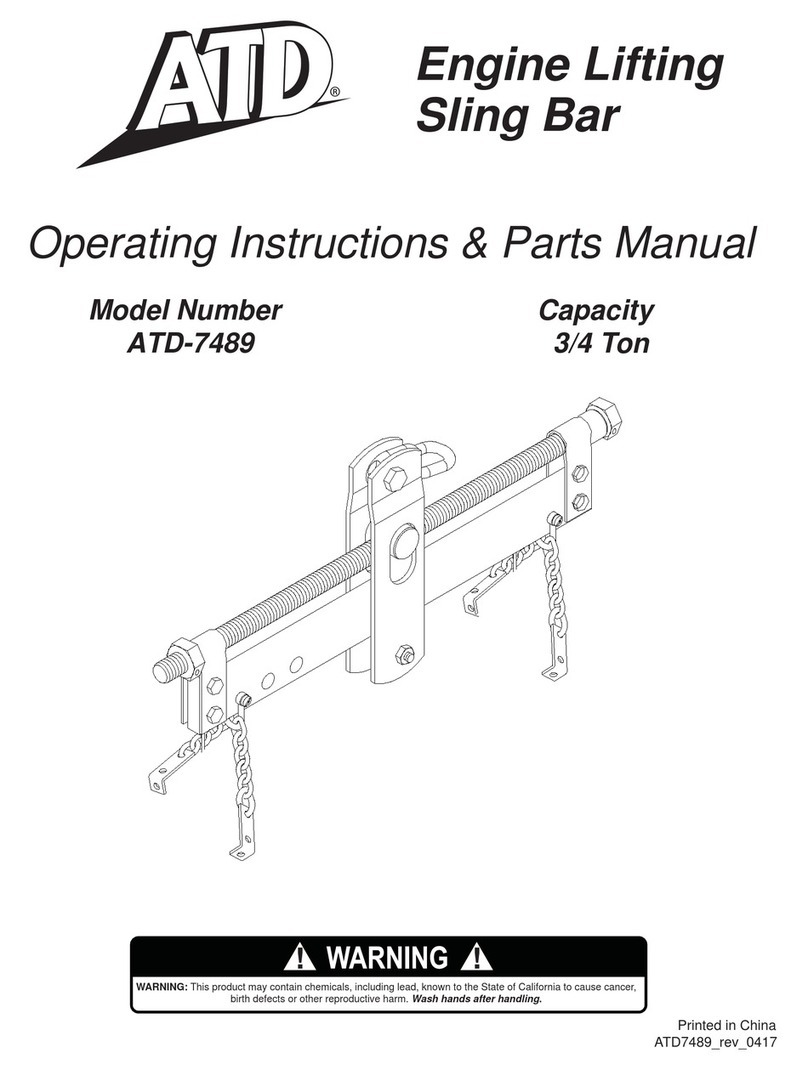

ATD Tools ATD-7489 Instructions for use

ATD Tools

ATD Tools ATD-7321A User manual

ATD Tools

ATD Tools ATD-7478 User manual

Popular Lifting System manuals by other brands

Stenhoj

Stenhoj MASCOT 1.25 Operation and maintenance instructions

Napa

Napa 791-7135 Operating manual & parts list

CHIEF

CHIEF Kahuna user manual

Rothewald

Rothewald 10059174 Assembly and operating instructions

Challenger Lifts

Challenger Lifts 40200 Operation installation maintenance manual

Sealey

Sealey MC455.V2 Instructions for use

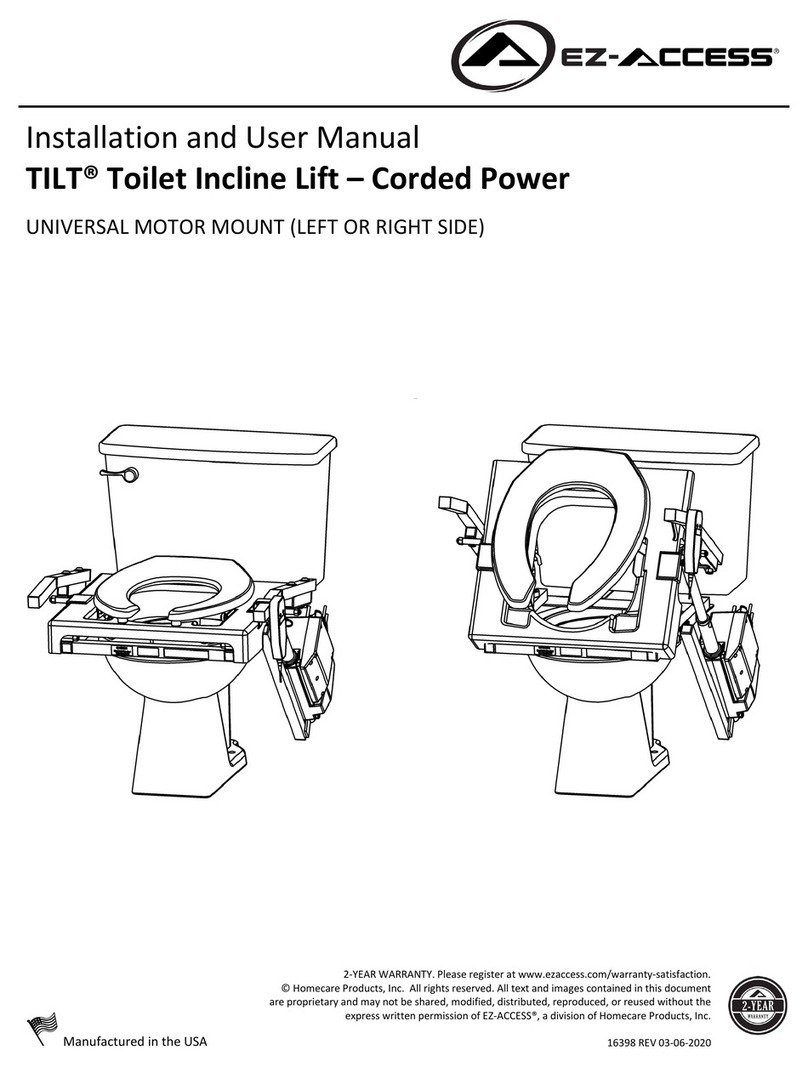

HOMECARE PRODUCTS

HOMECARE PRODUCTS EZ-ACCESS TILT Toilet Incline Lift Corded... Installation and user manual

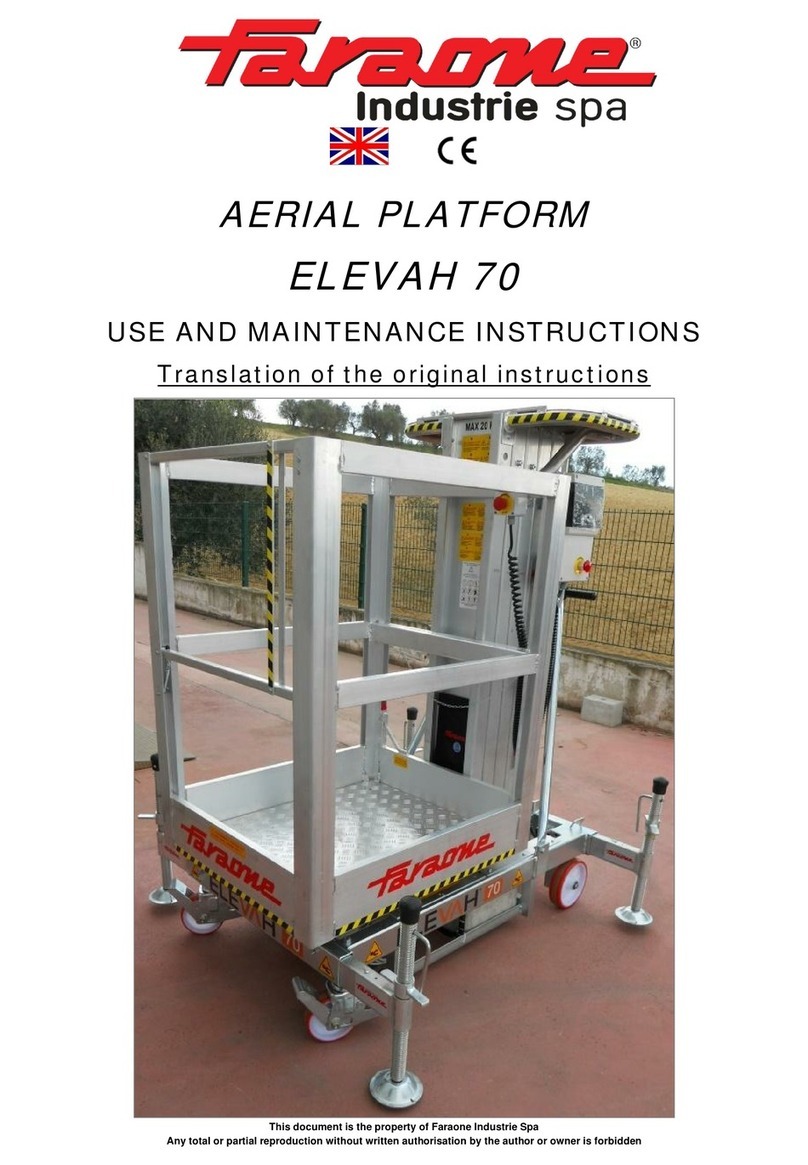

Faraone

Faraone ELEVAH 70 Use and maintenance instructions

Inter-fab

Inter-fab Portable i-Lift instruction manual

Parkside

Parkside PUTK 50 B1 operating instructions

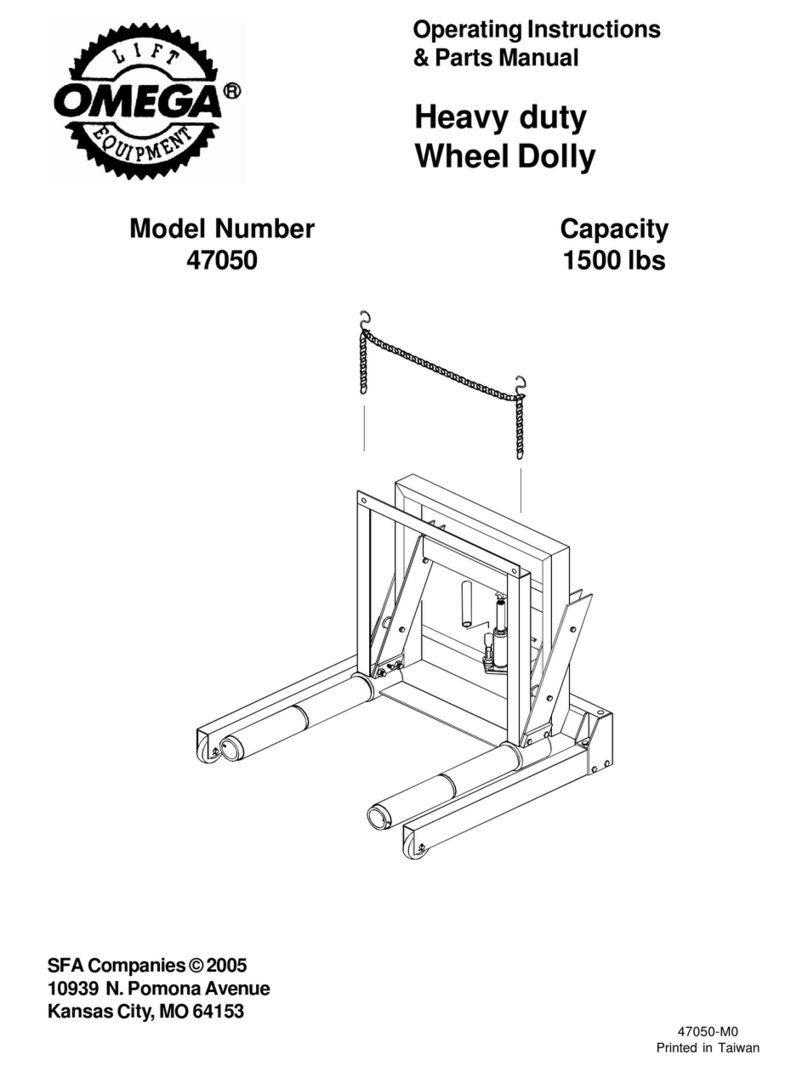

Omega

Omega 47050 Operating instructions & parts manual

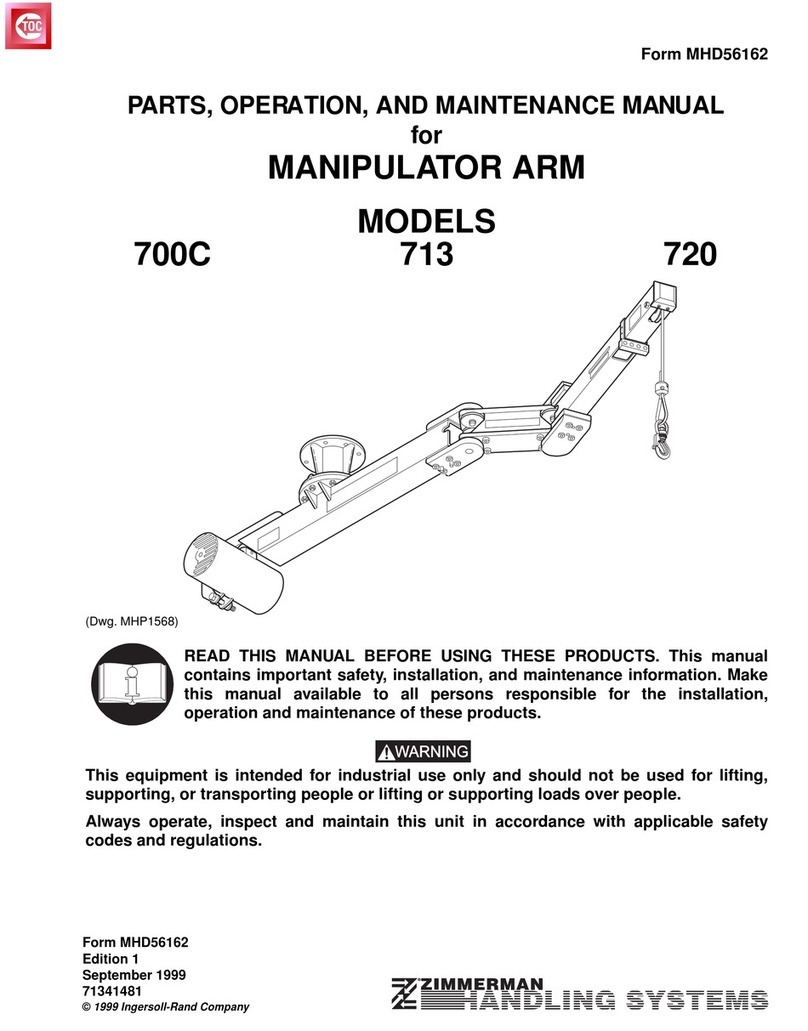

Ingersoll-Rand

Ingersoll-Rand 700C Parts, operation and maintenance manual