8

tDo not expose cylinders to electricity of

any kind.

tDo not use a cylinder or its contents for

anything other than its intended use. Do

not use as a support or roller.

tDo not locate cylinders in passageways

or work area where they may be struck.

tDo not use a wrench or hammer to open

a cylinder valve that cannot be opened

by hand. Notify your supplier.

tDo not modify or exchange gas cylinder

ttings.

tDo not deface or alter name, number or

other markings on a cylinder. Do not rely

on cylinder color to identify the contents.

tDo not connect a regulator to a cylinder

containing gas other than that for which

the regulator was designed.

tDo not attempt to make regulator repairs.

Send faulty regulators to manufacturer’s

designated repair center for repair.

tDo not attempt to lubricate a regulator.

tAlways change cylinders carefully to pre-

vent leaks and damage to their walls,

valves, or safety devices.

tAlways secure cylinders with a steel chain

so that they cannot be knocked over.

tAlways protect a cylinder, especially the

valve, from bumps, falls, falling objects

and weather. Remember that gasses in

the cylinders are under pressure and

damage to a regulator can cause the

regulator or portion of the regulator to

be explosively ejected from the cylinder.

tAlways make certain the cylinder cap is

securely in place on the cylinder, when-

ever the cylinder is moved.

tAlways close the cylinder valve and

immediately remove a faulty regulator

from service, for repair, if any of the fol-

lowing conditions exist.

tGas leaks externally.

tDelivery pressure continues to rise with

down stream valve closed.

tThe gauge pointer does not move o the

stop pin when pressurized or fails to

return to the stop pin after pressure is

released.

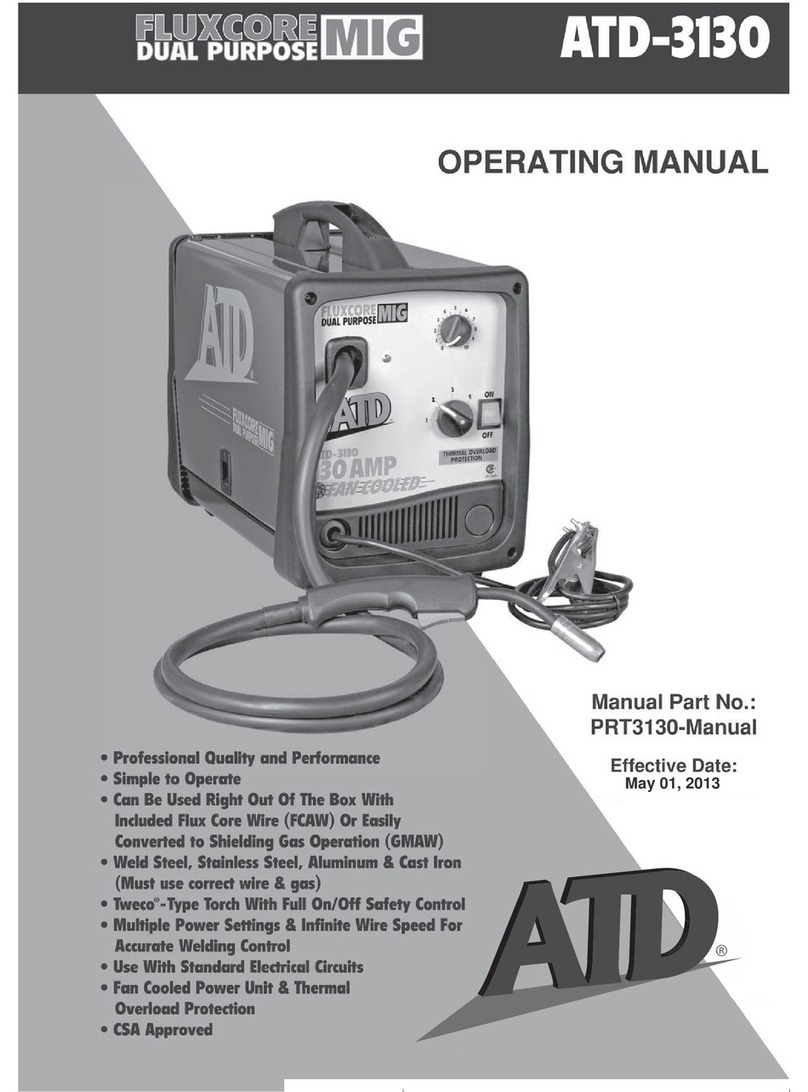

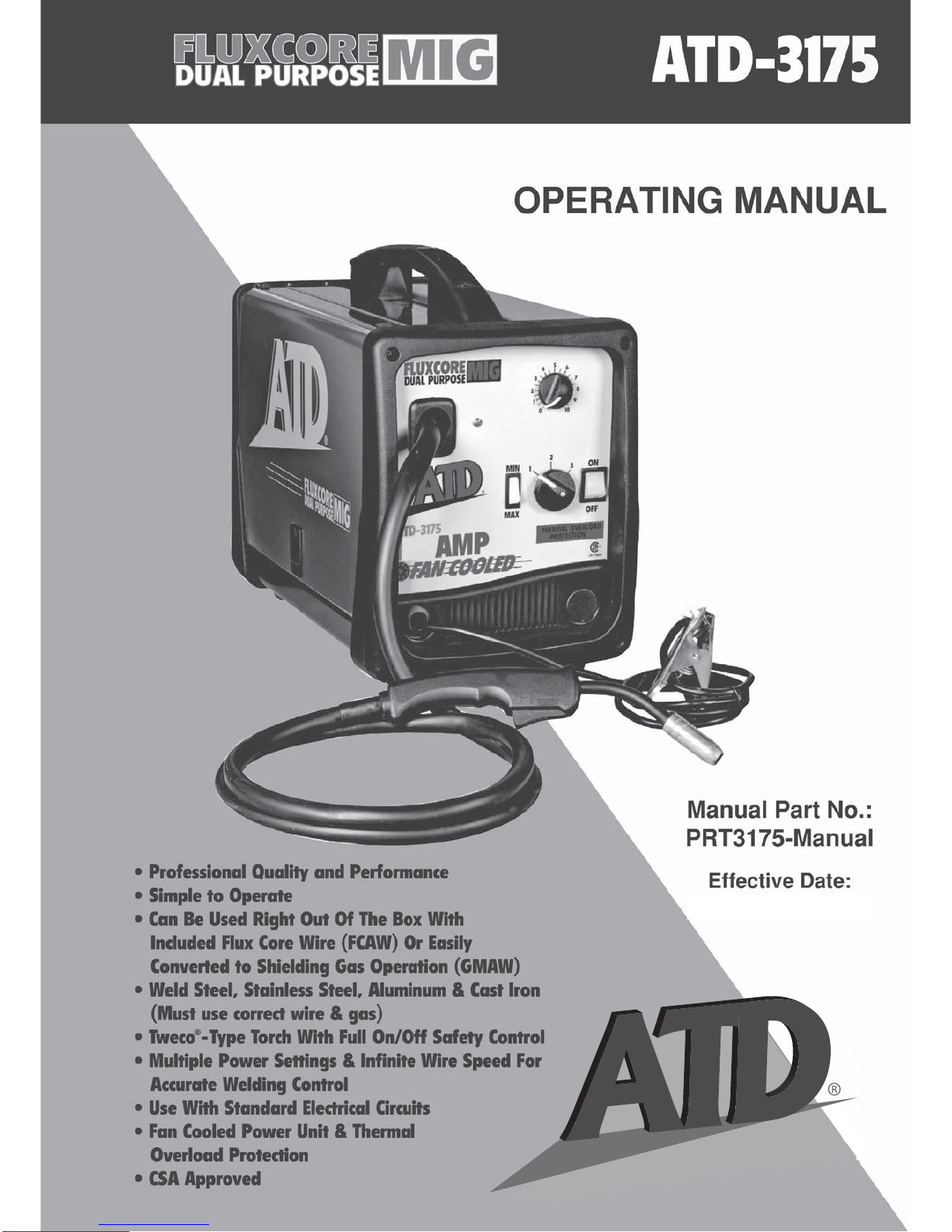

WARNING

This product contains chemicals, including

lead, or otherwise produces chemicals

known to the State of California to cause

cancer, birth defects and other reproductive

harm. Wash hands after Handling.

(California Health & Safety Code Sec.

25249.5 et seq.)

ADDITIONAL SAFETY INFORMATION

For additional information concerning weld-

ing safety, refer to the following standards

and comply with them as applicable.

tANSI Standard Z49.1 – SAFETY IN

WELDING AND CUTTING – obtainable

from the American Welding Society, 550

NW Le Jeune Road, Miami, FL 33126

Telephone (800) 443-9353, Fax (305)

443-7559 – www.amweld.org or

www.aws.org

tANSI Standard Z87.1 – SAFE PRACTICE

FOR OCCUPATION AND EDUCATION-

AL EYE AND FACE PROTECTION –

obtainable from the American National

Standards Institute, 11 West 42nd St.,

New York, NY 10036 Telephone (212)

642-4900,

Fax (212) 398-0023 – www.ansi.org

tNFPA Standard 51B – CUTTING AND

WELDING PROCESS – obtainable from

the National Fire Protection Association,

1 Batterymarch Park, P.O. Box 9101,

Quincy, MA 02269-9101 Telephone

(617) 770-3000

Fax (617) 770-0700 – www.nfpa.org

tOSHA Standard 29 CFR, Part 1910,

Subpart Q., WELDING, CUTTING AND

BRAZING – obtainable from your state

OSHA oce or U.S. Dept. of Labor

OSHA, Oce of Public Aairs, Room

N3647, 200 Constitution Ave.,

Washington, DC 20210 –

www.osha.gov

tCSA Standard W117.2 – Code for

SAFETY IN WELDING AND CUTTING. –

obtainable from Canadian Standards

Association, 178 Rexdale Blvd.,

Etobicoke, Ontario M9W 1R3 –

www.csa.ca

tAmerican Welding Society Standard

A6.0. WELDING AND CUTTING CON-

TAINERS WHICH HAVE HELD COM-

BUSTIBLES. – obtainable from the

American Welding Society, 550 NW Le

Jeune Road, Miami, FL 33126

Telephone (800) 443-9353, Fax (305)

443-7559 – www.amweld.org or

www.aws.org