6

graphite, cadmium, zink, chrome, mercury or beryllium,

unless you have the proper breathing set.

lThe electric arc creates ozone. A long exposure to high

concentrations may cause headaches, nasal, throat and

eye irritation as well as serious congestions and chest

pains.

IMPORTANT: DO NOT USE OXYGEN FOR VENTILA-

TION.

lGas leaks in a confined space should be avoided.

Leaked gas in large quantities can change oxygen con-

centration dangerously. Do not bring gas cylinders into a

confined space.

lDO NOT WELD where solvent vapors can be drawn into

the welding atmosphere or where the radiant energy can

penetrate to atmospheres containing even minute

amounts of trichloroethylene or perchloroethylene.

7.4 EXPLOSIONS

Do not weld above or near containers under pres-

sure.

lDo not weld in environments containing explo-

sive dusts, gases or vapours.

This welding machine uses inert gases such as CO2,

ARGON, or a mixture of ARGON + CO2 for the protection

of the arc, thus you should take special precautions:

A) CYLINDERS

lDo not directly connect cylinder to the machine gas hose

without a pressure regulator.

lHandle or use pressure cylinders in conformity with the

existing rules.

lDo not use leaking or damaged cylinders.

lDo not use cylinders which are not well secured.

lDo not carry cylinders without the protection of the

installed valve.

lDo not use cylinders whose content has not been clear-

ly identified.

lNever lubricate cylinder valves with oil or grease.

lDo not put the cylinder in electrical contact with the arc.

lDo not expose cylinders to excessive heat, sparks,

molten slags or flame.

lDo not tamper with the cylinder valves.

lDo not try to loosen tight valves by means of hammers,

keys, or any other object.

lNEVER DEFACE or alter name, number, or other mark-

ings on a cylinder. It is illegal and hazardous.

lDo not lift cylinders off the ground by their valves or

caps, or by chains, slings or magnets.

lNever try to mix any gases in a cylinder.

lNever refill any cylinder.

lCylinder fittings should never be modified or exchanged.

B) PRESSURE REGULATORS

l Keep pressure regulators in good condition. Damaged

regulators may cause damages or accidents, they should

only be repaired by skilled personnel.

l Do not use regulators for gases other than those for

which they are manufactured.

l Never use a leaking or damaged regulator.

l Never lubricate regulators with oil or grease.

C) HOSES

lReplace hoses which appear damaged.

lKeep hoses unwound in order to avoid bending.

lKeep the excess hose wound and out of the working

area in order to avoid any damage.

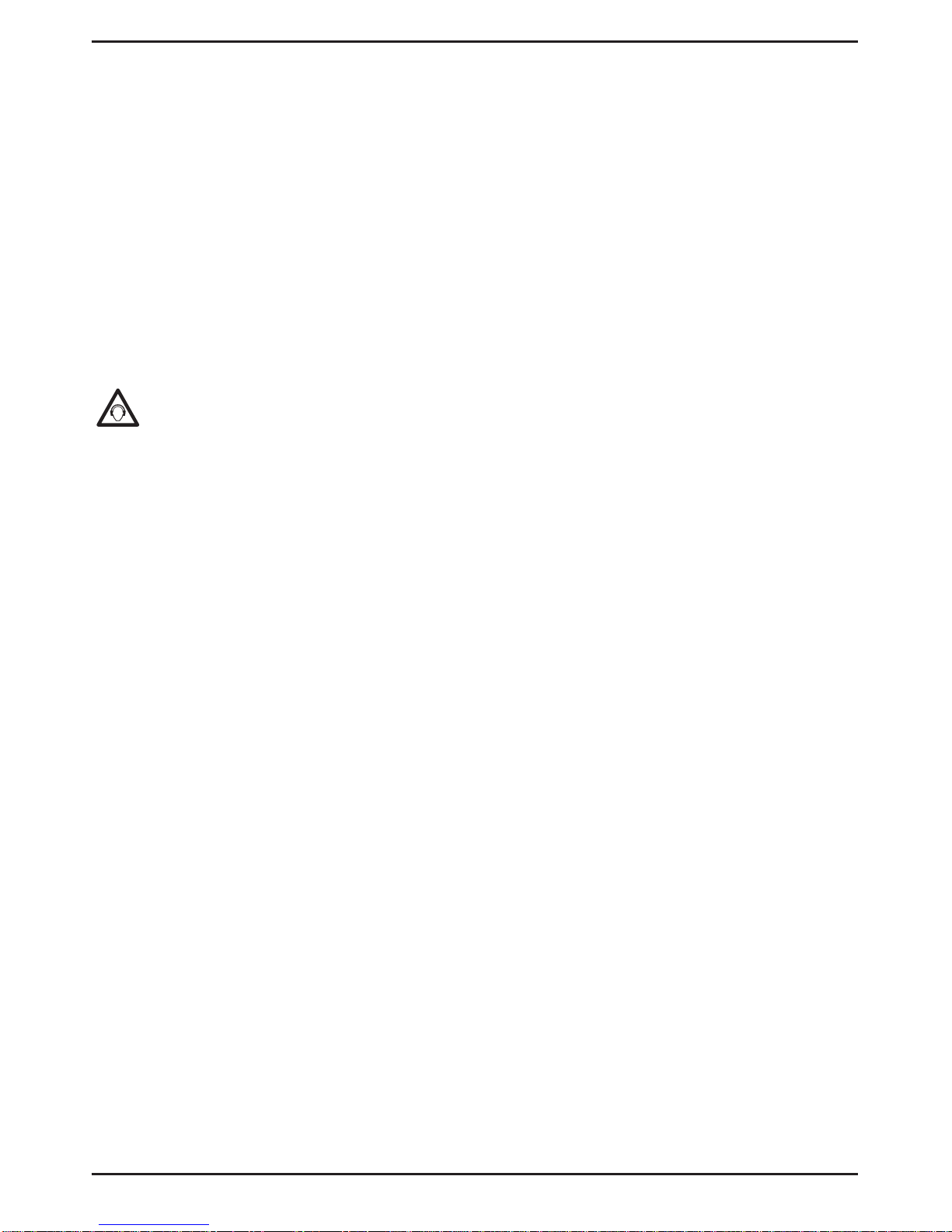

7.5 RADIATIONS

Ultra-violet radiation created by the arc may dam-

age your eyes and burn your skin.Therefore:

lWear proper clothing and helmet.

lDo not use contact lenses!! The intense heat coming

from the arc may cause them to stick to the cornea.

lUse masks with grade DIN 10 or DIN 11 safety lenses at

the least.

lProtect people in the surrounding welding area.

Remember: the arc may dazzle or damage the eyes. It is

considered dangerous up to a distance of 15 meters (50

feet). Never look at the arc with the naked eye.

lPrepare the welding area so as to reduce reflection and

transmission of ultra-violet radiation. Paint walls and

exposed surfaces in black to reduce reflection, install

sheathings or curtains to reduce ultra-violet transmis-

sions.

lReplace mask lenses whenever damaged or broken.

7.6 ELECTRIC SHOCK

Electric shock can kill.

All electric shocks are potentially fatal.

l Do not touch live parts.

lInsulate yourself from the piece to be cut and from the

ground by wearing insulated gloves and clothing.

lKeep garments (gloves, shoes, hats, clothing) and body

dry.

lDo not work in humid or wet areas.

lAvoid touching the piece to be welded.

lShould you work close to or in a dangerous area, use all

possible precautions.

lIf you should feel even the slightest electric shock sen-

sation, stop welding immediately. Do not use the machine

until the problem is identified and solved.

lAlways fit an automatic wall switch with adequate power,

possibly close to the machine, allowing you to immediate-

ly switch the machine off in case of an emergency.

lFrequently inspect the power supply cable.

lDisconnect power supply cable from mains before

replacing cables or before removing unit covers.

lDo not use the unit without protection covers.

lAlways replace any damaged parts of the unit, with orig-

inal material.

lNever disconnect unit safety devices.

lMake sure that the power supply line is equipped with an

efficient earth plug.

lMake sure that the work bench and the workpiece are

connected to an efficient earth plug.

lAny maintenance should only be carried out by qualified

personnel aware of the risks due to dangerous voltages

necessary for the operation of the unit.

7.7 PACE MAKER

lMagnetic fields from high currents can affect pacemak-

er operation. Persons wearing electronic life support

equipment (pacemaker) should consult their doctor before

going near arc welding, gouging or spot welding opera-

tions.

7.8 CAUTION! WELDING WIRE CAN CAUSE PUNCTU