Power steering parts

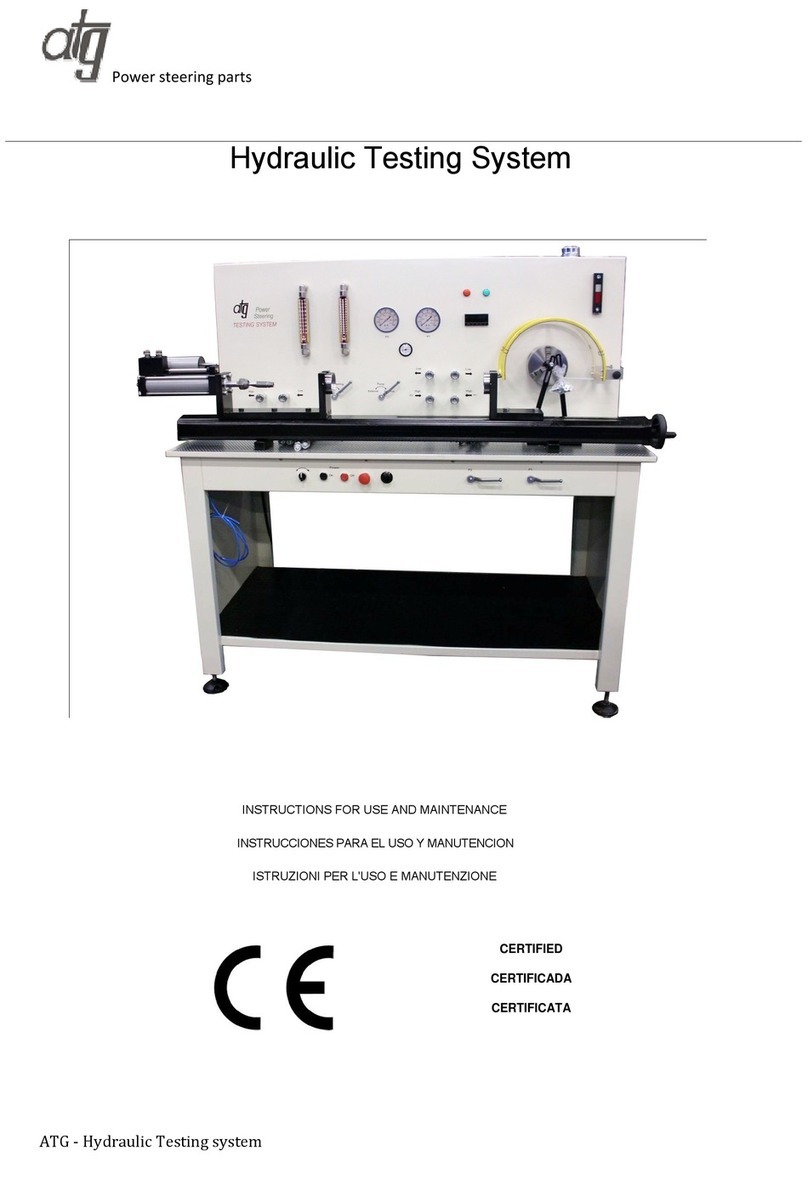

ATG - Eps Testing system

acceleration does not exceed 2.5m/s².

The measurements are taken in accordance

with standards UNI7712, ISO3740, ISO 3746 and

EC/2006/42.

The emission levels indicated are not necessarily safety

levels. Although there is a relationship between the

emissions and exposure levels, the values shown cannot

be used for establishing the need for further precautions.

There are other factors which influence the exposure

levels of operators, such as the features of the work place,

presence of other sources of noise, number of machines

running, etc.

The exposure levels may also vary between countries.

This information is necessary for the user for better

evaluation of the risks and hazards deriving from noise.

1.8 INFORMATION ABOUT ELECTROMAGNETIC

COMPATIBILITY

The european regulations on safety and in particular

the EEC directive 2004/108 contemplate that all the

equipment be equipped with shielding devices against

radio interferences both from and towards the outside.

This machine is equipped with filters both on the motor

and on the power supply through which the machine is

safe and in compliance with above regulations.

Tests were carried out according to 61000-6-1, EN

61000-6-3, EN 55014-1, EN 55014-2 regulations.

1.9 DESCRIPTION OF THE MACHINE (Fig. 1)

The machine consists of a machine body D complete with

brake F and gear.

In the base N there are: EPS plate for B, and a plate for

electric rack C and a rack E.

The EPS and electric rack are fixed with the tool L. The

electrical connections are made with cables I, diagnosis by

means of the cable 6.

There are also a power supply G, a computer H, a monitor

A, a battery N.

A Monitor

B Eps plate

CElectric rack plate

D Machine body

E Rack

F Brake

G Power supply

H Computer

I Cables

L Tool

M Cable 6

N Battery

VERSIONE EPS

WEIGHT: ............................................................... 500 Kg.

SIZE:.............................................cm 1000x1500 x H 1800

PACKAGING SIZE: .....................cm 1770X1240 x H 1760

2 INSTALLATION

2.1 REMOVING THE PACKING

The machine is delivered inside a box suitable for the

purpose.

Therefore, the packing must be removed completely by

means of suitable tools and care must be take in order to

avoid damage to any part of the machine.

For packing disposal, please refer to 6.4 point.

2.2 HANDLING AND TRANSPORTION (Fig. 2)

The machine and must be moved only using suitable lifting

devices.

WARNING: Do not try to move or lift the

machine by hand even if more people are

present.

WARNING: The operations described in this

manual relative to sling, transport and lifting

by means of a fork lift or hoist must be carried

out only by skilled and qualified personnel

(EC/2006/42).

Move the machine carefully and avoid sudden movements

which could unbalance the load and make it drop.

To remove themachine from the plate after packing removal,

loosen the fixing screws but keep them should the machine

be transported for long stretches.

To move the machine while it is still inside the packing, use

a fork lift by inserting the two forks in the rooms provided

under the hearing board.

2.3 ELECTRICAL CONNECTIONS

Check that the mains to which the machine is connected is

earthed in accordance with current safety regulations and

that the power point is in good condition.

Connect a plug in compliance with safety rules to the

end of the mains cable of the machine, checking that the

yellow/green protective conductor is fitted into the relative

terminal marked.

Remember that there should be a magnetothermic

protective device fitted upstream of the mains to protect all

the conductors from short circuits and overloads.

This protective device should be selected according to the

electrical features of the machine stated on the motor.

The motor of your machine is equipped with a protective

heat circuit breaker which interrupts the power supply

when the temperature of the coils rises too high.

When the power supply is interrupted, wait for normal

reset.

UNIVERSAL VERSION (Fig. 4)

In case of power failure in mains, while you wait for power

to be restored there is no danger hazard may arise : in

fact, the electronic speed variator is also equipped with a

reset function which prevents the machine from re-starting

automatically. To start the machine, press the start push

button A on the handgrip twice.

WARNING: Never change setting to avoid

overloads which could damage the electric

circuits and other mechanical members.

Your machine is equipped with a motor protection

obtained through a amperometric limiter which prevents

the motor from absorbing a current higher than the set

one, expressed by the maximum prescribed value of

absorption.

2.4 POSITION/WORK STATION (Fig. 2)

Position the machine by moving it as described in

paragraph 2.2

Taking the ergonomic criteria into consideration, the ideal