Manual, Collision Sensor, Protector™,SR-61

Document #9610-60-1006-13

Pinnacle

Park

•

1031

Goodworth

Drive

•

Apex,

NC

27539

USA

•

T

el:

919.772.01

15

•

Fax:

919.772.8259

•

www

.ati-ia.com

•

Email:

[email protected] 3

Table of Contents

1. Safety......................................................................................................................................... 6

1.1 ExplanationofNotications.........................................................................................................6

1.2 General Safety Guidelines............................................................................................................6

1.3 Safety Precautions........................................................................................................................7

2. Product Overview..................................................................................................................... 8

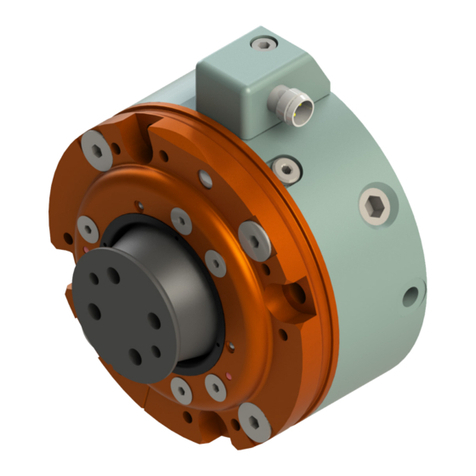

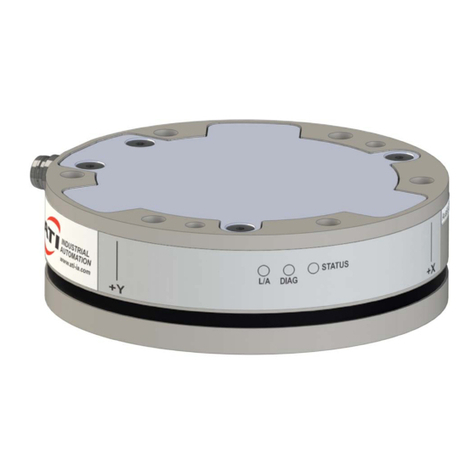

2.1 Product Description......................................................................................................................8

3. Installation ................................................................................................................................ 9

3.1 Mechanical Installation.................................................................................................................9

3.1.1 FastenerTorqueSpecications ..........................................................................................9

3.2 Electrical Connection..................................................................................................................10

3.2.1 Test Switch Functionality.................................................................................................. 11

3.3 Pneumatic Connection ............................................................................................................... 11

3.3.1 Operating Requirements.................................................................................................. 11

3.3.2 Calculating Estimated Pressure Setting........................................................................... 11

3.3.2.1 Calculate Applied Loads ................................................................................... 11

3.3.2.2 Obtain Required Pressure Setting....................................................................13

3.3.3 Determining Exact Pressure Required.............................................................................14

4. Operation ................................................................................................................................ 15

5. Maintenance............................................................................................................................ 16

5.1 Periodic Lubrication Instructions..............................................................................................16

5.1.1 Cover Plate and Stem Disassembly.................................................................................16

5.1.2 Cover Plate and Stem Cleaning and Lubrication .............................................................17

5.1.3 Cover Plate and Stem Re-assembly................................................................................18

6. Troubleshooting ..................................................................................................................... 19

6.1 Cable Replacement.....................................................................................................................20

6.2 Replacement of Switch/Connector Block Assembly ...............................................................20

6.2.1 Replacement of Original Style Switch/Connector Block Assembly ..................................21

6.2.2 Replacement of Current Style Switch/Connector Block Assembly...................................22

6.3 Switch Adjustment......................................................................................................................23

6.3.1 Original Style Switch Adjustment......................................................................................23

6.3.2 Current Style Switch Adjustment......................................................................................24

6.4 Spring Conversion......................................................................................................................26

6.5 Seal Replacement........................................................................................................................27

6.6 IP65 Boot Replacement ..............................................................................................................28

6.7 Weld Splatter Shield Replacement............................................................................................29

6.8 Flexible Boot Replacement ........................................................................................................30