IOM1030 ATI Scotch Yoke M-Series Actuator

2

Table of Contents

1Introduction ....................................................................................................................... 3

1.1 Company Background .............................................................................................................................3

1.2 Scope & Purpose of Manual ....................................................................................................................3

1.3 Company Contact ....................................................................................................................................3

2Reference Documents ........................................................................................................ 4

3Definitions ......................................................................................................................... 4

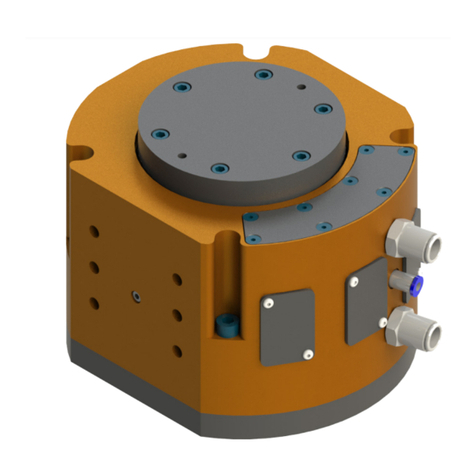

4Product Description........................................................................................................... 5

4.1 General Description & Typical Applications...........................................................................................5

4.2 Theory of Product Operation ...................................................................................................................5

4.3 Scotch Yoke Actuators ............................................................................................................................5

4.4 Product Specifications .............................................................................................................................6

5Safety Warnings ................................................................................................................ 8

5.1 Personnel Requirements ..........................................................................................................................8

5.2 Potential Hazards .....................................................................................................................................9

6Handling and Storage.......................................................................................................10

6.1 Receiving the Product............................................................................................................................10

6.2 Storage and Preservation .......................................................................................................................10

7Installation Instructions...................................................................................................11

7.1 Scotch Yoke/Quarter-Turn Actuators ....................................................................................................11

7.2 Setting the Stroke Length ......................................................................................................................11

8Preparation for Start-up...................................................................................................12

8.1 Hydraulic Oil Use ..................................................................................................................................12

8.2 Hydraulic & Pneumatic Connections.....................................................................................................12

8.3 Limit Switch Instructions.......................................................................................................................12

8.4 Start-up ..................................................................................................................................................12

9Maintenance & Operation ................................................................................................13

Safety Reminder..................................................................................................................................................13

9.1 Routine Maintenance .............................................................................................................................13

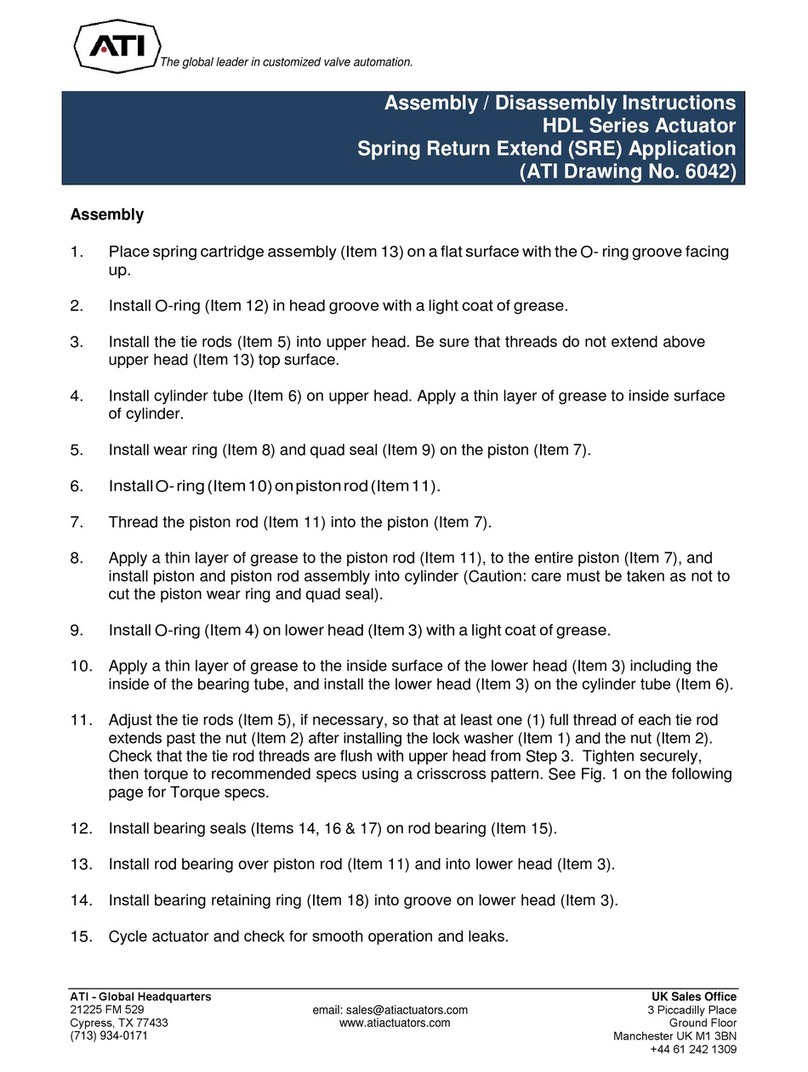

9.2 Double Acting Disassembly ..................................................................................................................14

9.3 Spring Return Disassembly ...................................................................................................................14

9.4 Seal Replacement...................................................................................................................................14

9.5 Double Acting Reassembly ...................................................................................................................15

9.6 Spring Return Reassembly.....................................................................................................................16

9.7 Double-Acting Operation ......................................................................................................................16

9.8 Spring Return Operation........................................................................................................................17

9.9 Lubricating Mechanism .........................................................................................................................17

9.10 Parts Ordering........................................................................................................................................18

10 Disposal.............................................................................................................................19

11 Terms and Conditions/Warranty .....................................................................................20

12 Revision Record ................................................................................................................22

Appendices