© ATL Agricultural Technology Limited: July 2009

MK3 OUT OF

PARLOUR REVIVER

INSTALLATION: 1

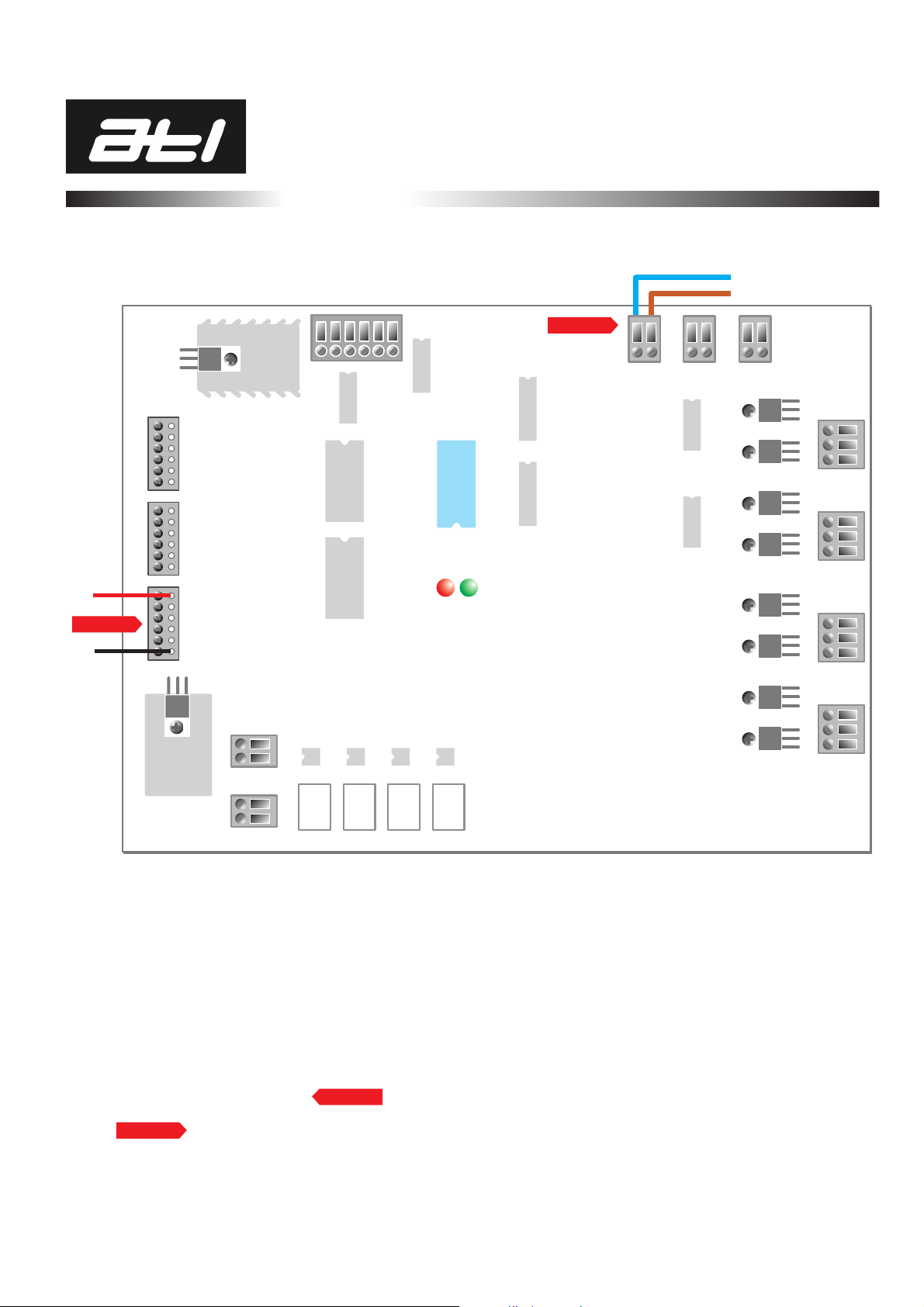

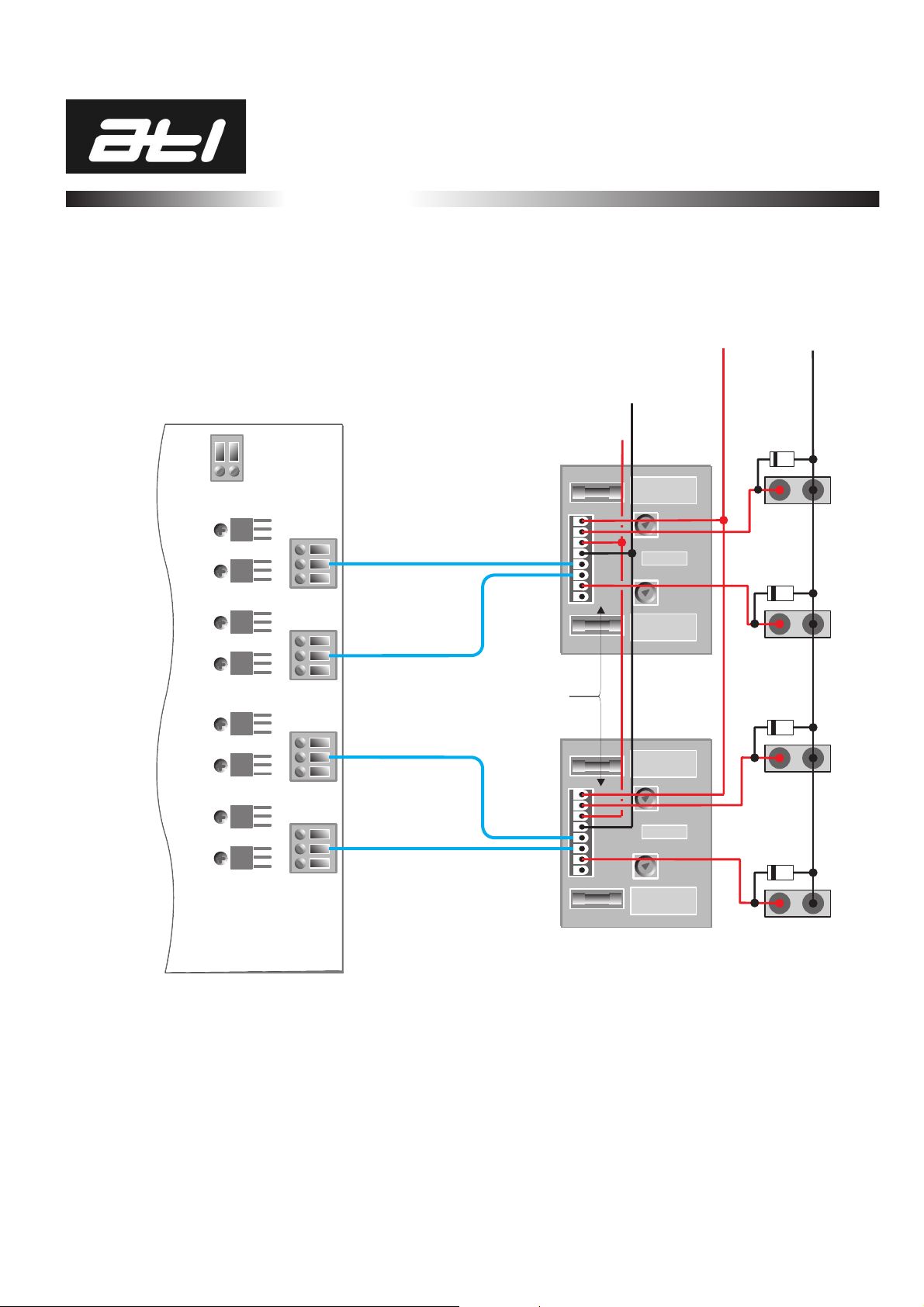

DataCables

Out-Of-ParlourInterfaceandFeederCables:

The data cable supplied is ‘twisted pair’configuration especially designed for communications.

No other cables should be used as replacements. Ensure it is connected exactly as shown in the

diagramsand keepthecablerun asshort aspossible.

Do not run near or parallel to, or cross over AC mains supplies or wires carrying switched

current(i.e.milkpumps).

Generallyavoidfluorescentlightingor radiowavesources.

Ideally, data cable should be run through a suitable conduit by itself, esoecially if it is

exposedtotheweather.Sharingconduitwithpowerwiresinvariablycorruptsdata.

Sufficientco-axialcableisprovidedtowire thestallantennasto the Out-Of-ParlourInterface.

Cable entries into control box MUST be made through the glands provided. Never cut

new entries into the top or sides of the casing. This will automatically invalidate

anywarranties.

ALWAYS use the correct csa (cross sectional area) cable specified in the diagrams.

Environmental Considerations

ATL Out Of Parlour Control equipment is built to the highest specifications to give faithful and

reliable service for years and years. However, it could deteriorate prematurely if a few simple

stepsarenottaken tosafeguardit.

Good ventilation is essential. Fresh air is not only good for animals but also dissipates the

highlycorrosivegasesproducedbysilage,slurry,andsome feedstuffs

PositionOut OfParlourstallswherethereis plentyofair movement.Stale air willcollectin

enclosed corners of even large buildings. Exposed concentrates will deteriorate rapidly

where ventilation is inadequate. Air circulation can be improved by replacing some of the

sheetedcladdingwithYorkshireBoarding.

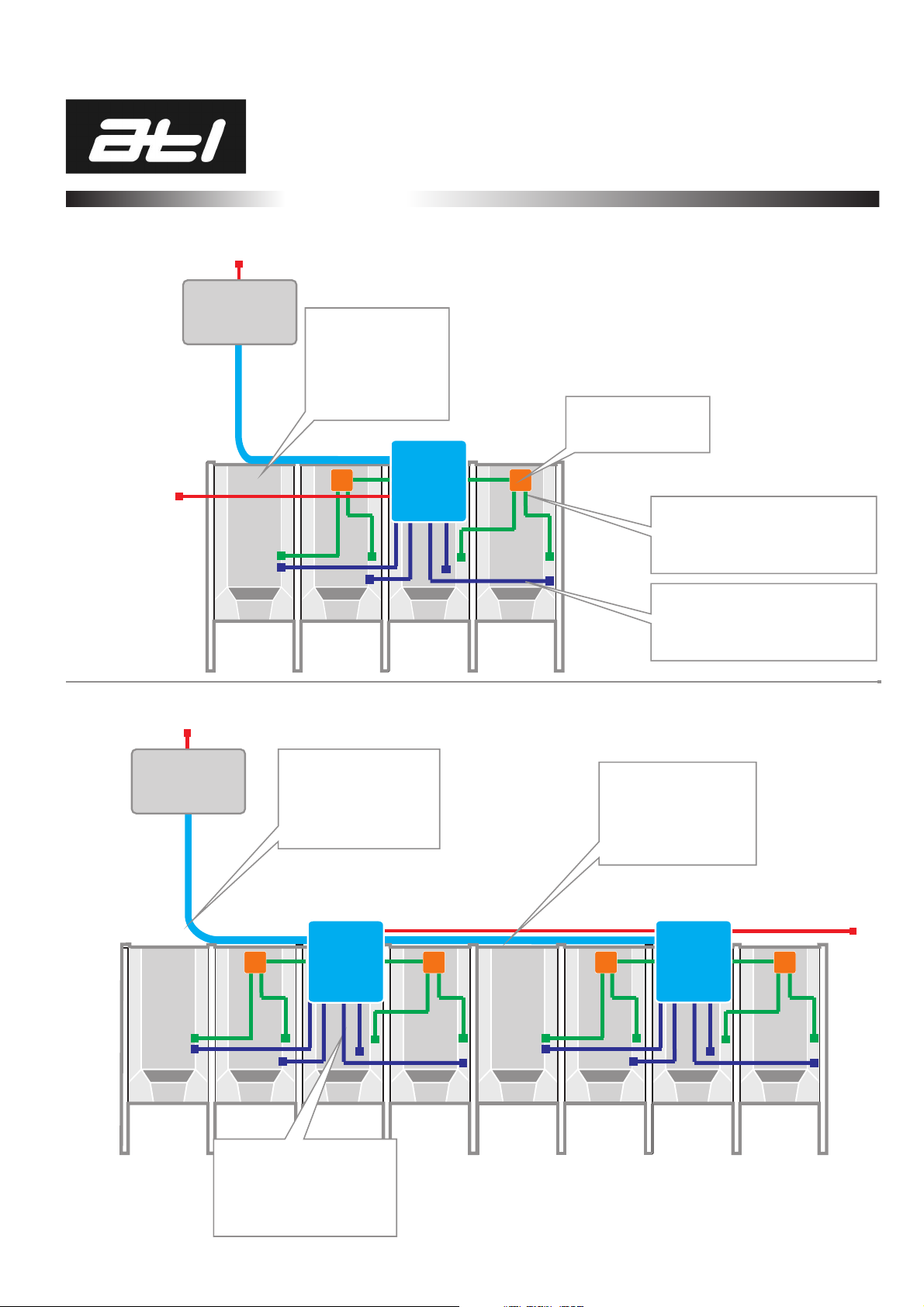

About the ATL Out-Of-Parlour System

The high-speed scanning system addresses each stall in turn seeking a valid ear tag read and so

makes any other form of animal detection unnecessary. Each system contains one (1) Interface

for every 4 feeders, a Console Display Unit, a power supply and a varying number of stalls

depending on system size. Only 1 reader is required per system and this is normally located in

theInterfaceforfeeders1-4.

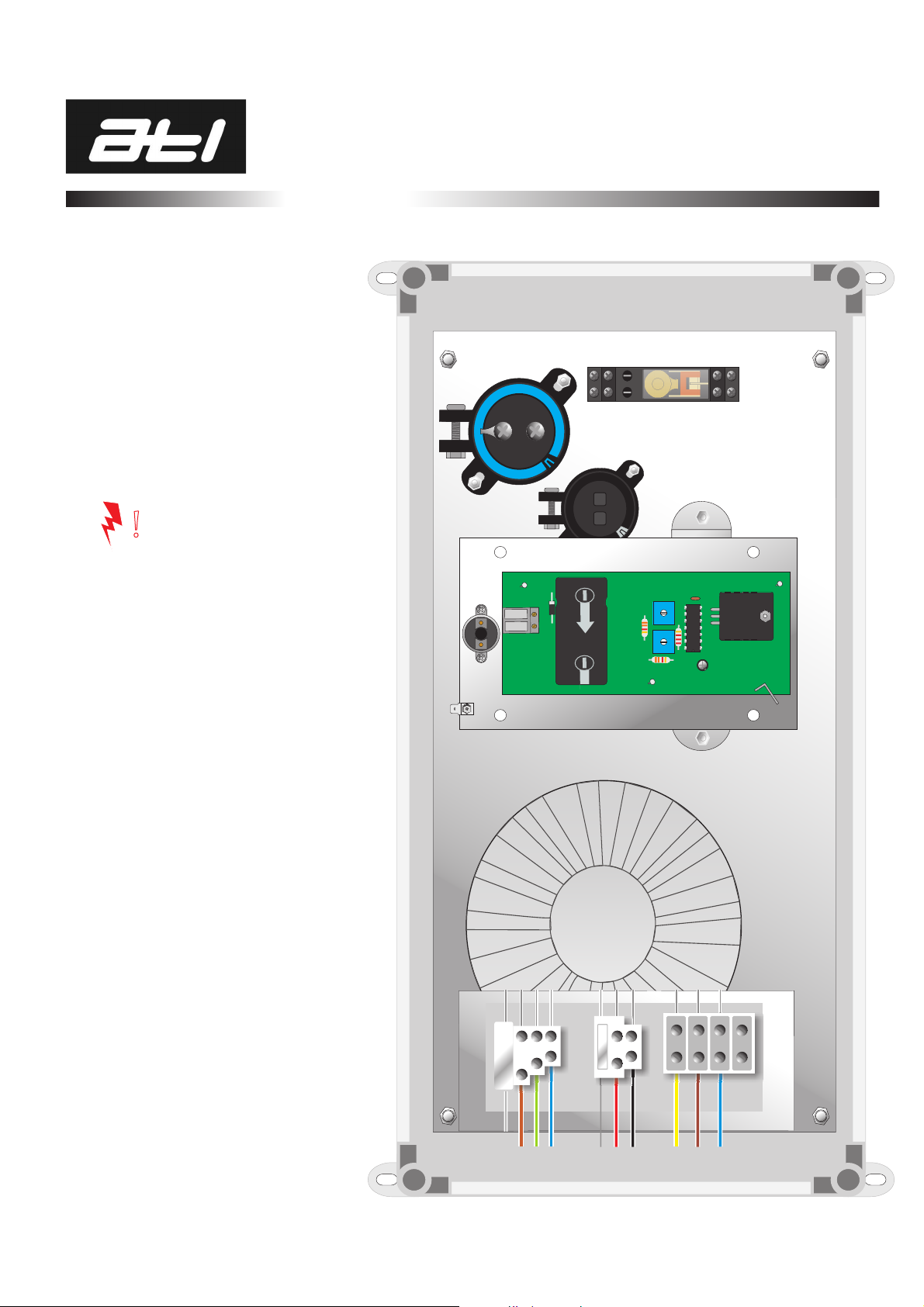

The Interface contains all of the electronics to detect the presence of an ear tag in a stall,

relay that information back to the Console unit, receive the ration allocation from the

Console and drive the appropriate stall feeder. It can provide the tag reading facility for

almost any number of stalls providing they are not too widely spaced (100 metres absolute

maximum) and drive the first 4 feeder motors. For additional stalls extra Interfaces are required

eachcapableofdrivingupto 4 feeders.

Systems which have second feeders (B) are fitted with an additional, smaller circuit board sited

ontop of themain board.Thiscarriesthedrivecircuitsforthe secondfeeders.

The portable Console unit contains the computing circuitry, stores the herd data and controls the

tag reading and feeding process. It must be connected for the system to operate. Generally, the

Console should be kept and used in a dry environment such as the farm office and may be

connected to the feeder stalls by up to 100meters of special data cable. Power is derived from a

small power supply that is plugged into a standard 13amp mains socket (230v AC) in the office

environment.

n

n

n

n

n

n

n