FS12TEN-99

Owner’s Manual

AtlasIED.com

TELEPHONE: (800) 876-3333

SUPPORT@ATLASIED.COM

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

– 5 –

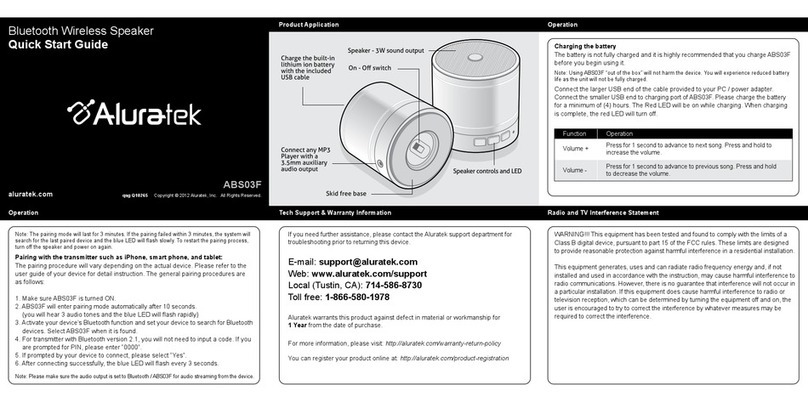

Installation via Mounting Bracket (Included)

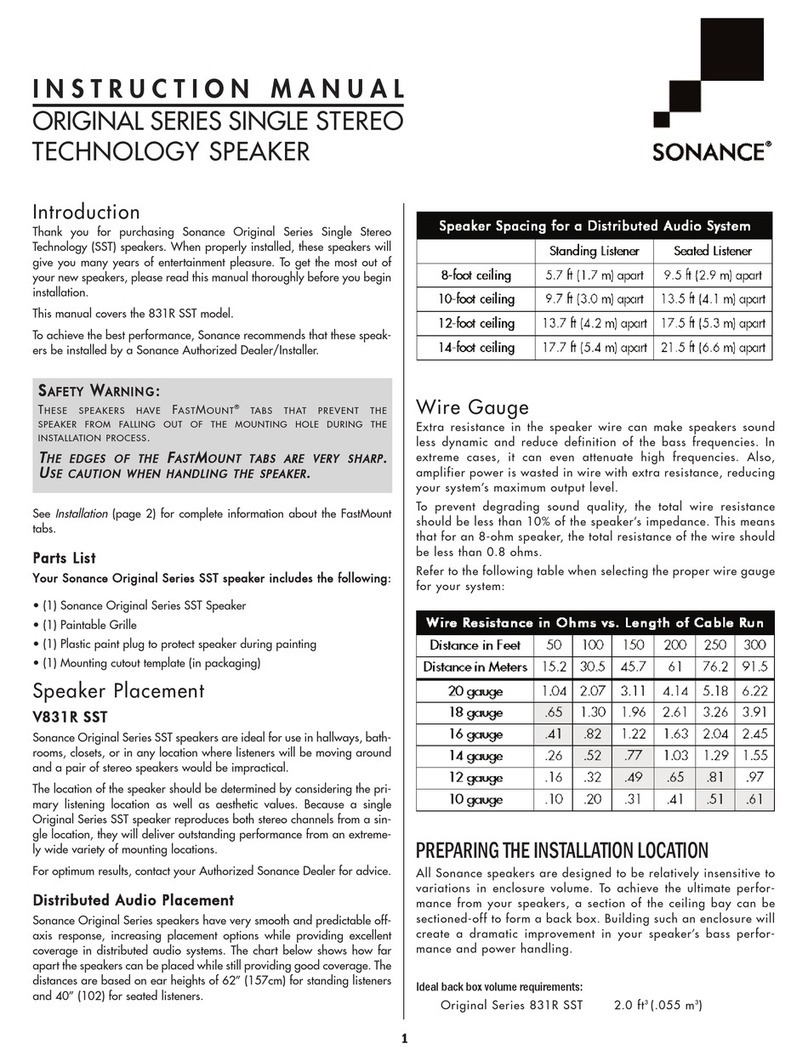

General considerations and hardware recommendations:

CAUTION: FS12TEN Series models weigh as much as 50 pounds (22.7 kg) – model FS12TEN-99. A fall from almost any height could result in serious injury

or death. Assure that the loudspeaker is firmly mounted to an object that can handle its weight. Remember that wind will add considerable torque to

the point of attachment. The mounting surface the FS12TEN loudspeaker is being attached to should be able to handle five or more times the weight of

the FS12TEN loudspeaker (7x is recommended for locations subject to high wind forces).

Whenever the loudspeaker is mounted to a surface using the bracket, the installer must ensure that the surface is capable of safely and securely

supporting the load. The hardware employed must be safely and securely attached both to the loudspeaker and the surface in question, using only the

mounting holes. A general rule for soft surface installations (wood beams) is to multiply the corresponding working load limit by 75%; the result will be

an approximate working load strength.

Use thread locking compound for all installations.

CAUTION: Mount the speaker such that the shear force is at a right angle to the mounting bolts, and as close to the connection, as shown:

Mounting

CAUTION: Mounting the FS12TEN loudspeaker requires two people, unless it is possible to safely clamp the loudspeaker in position for alignment before

mounting.

The bracket may be removed from the loudspeaker for installation convenience. When re-attaching loudspeaker to bracket be sure to tightly secure

loudspeaker mounting bolts. A semi-permanent thread locking compound should also be used in this operation.

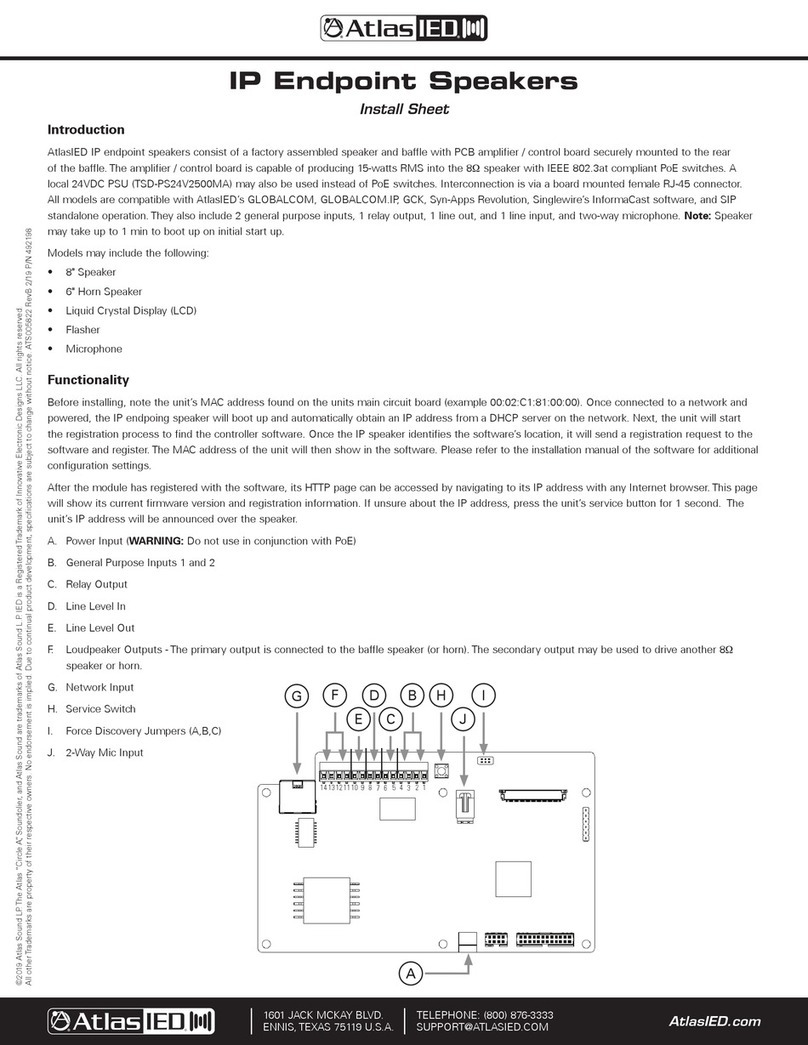

1. Choose the center mounting hole or any two of the 10mm bracket mounting holes best suited for the surface you are mounting to. For best

stability using 2 holes is recommended.

2. When using these mounting holes 10mm (stainless steel A193 grade B8 hardware is recommended for high strength outdoor installations).

Stainless flat and lock washers must also be used. Remember to use semi-permanent thread locking compound on threads.

3. Use the dimensions noted on the illustration to mark the points for drilling holes.

4. Choose appropriately sized bit and drill holes.

5. Attach loudspeaker bracket, using bolt, flat washer, and lock washer as shown and re-attach loudspeaker to bracket.

6. Secondary (safety) suspension point: Use a load rated cable or steel chain (capable of holding the loudspeaker should it come loose from the

primary mounting point). This cable or chain assembly should be attached to and secured to the mounting surface via approved, load rated

hardware.

When mounting the FS12TEN loudspeaker to a solid surface use the proper bolts, washers, and lock washers (stainless steel A193 grade B8 is

recommended for high strength outdoor installations). Do not substitute mismatched bolts and washers.

The FS12TEN loudspeaker may be mounted to a pole or scoreboard. For such mounting, contact the light pole or scoreboard manufacturer for proper

instructions. If mounting to another surface, such as a beam, see the diagram on page 3. When in doubt contact a qualified structural/mechanical

engineer for approval of the mounting materials and methods.