10 Manual No:I.HPL450LED.01ATM Lighting sp. z o.o.,

Release date: 17.11.2023ul. Maszynowa 30A,80-298 Gdańsk,

Edition: 1.0 tel: +48 58 347 51 07, fax: +48 58 347 51 08

Remarks:

•Use one wrench to tighten the sealing nut, while using the second wrench to block gland body

against rotation, otherwise damage of the sealing can be caused and therefore sealing level

will be decreased.

•Not following this remark may cause damage to the seals, resulting in a lowering of the IP

rating and damage to the luminaire in the result.

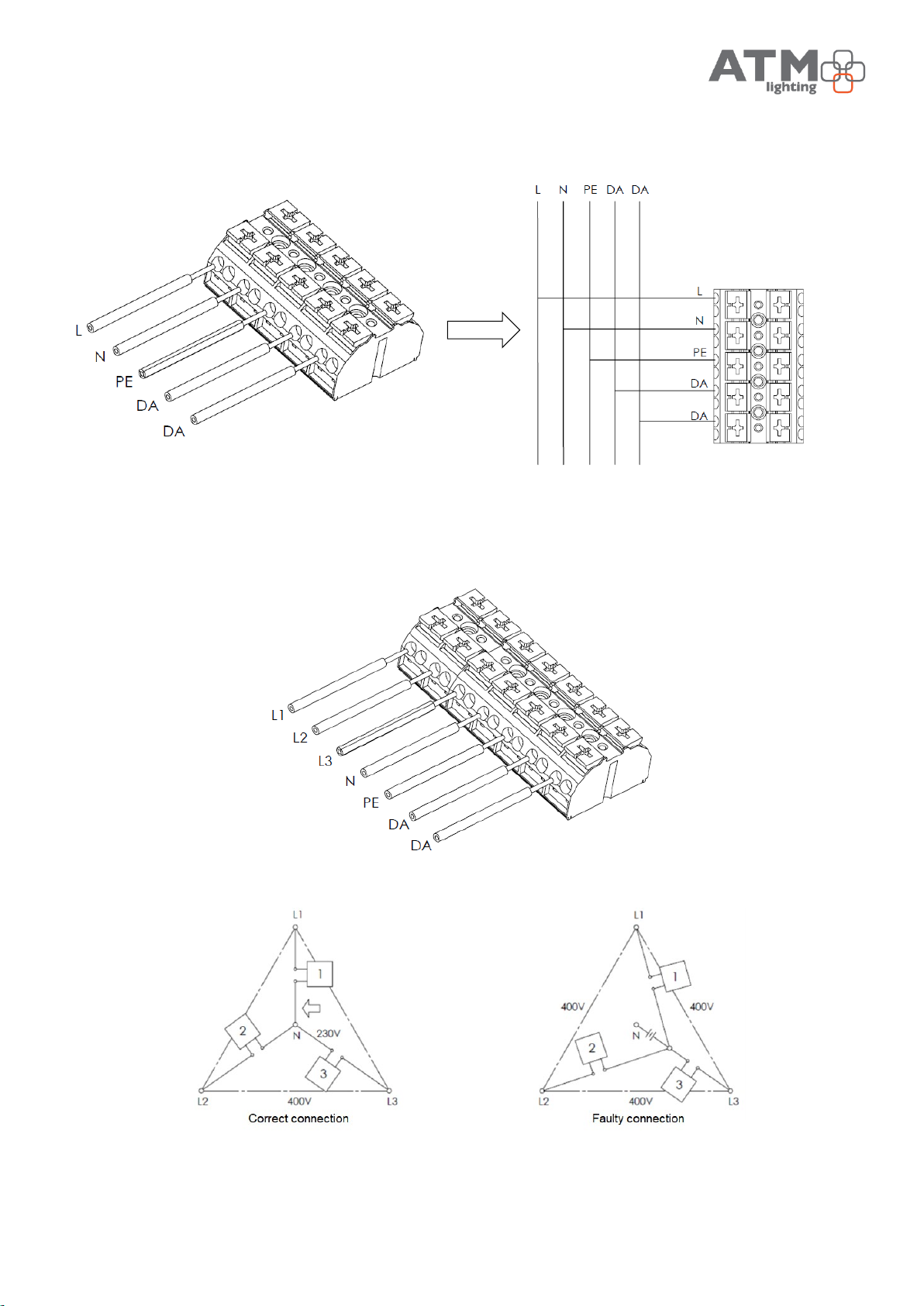

•If the neutral line is damaged or voltage occurs in it, a floodlight or group of floodlights may

start to work under larger than predicted load, witch in consequence may lead to damage of

power delivery system.

8. CONDITIONS OF SAFETY USE

•Every light fitting must have label with rating data on it. Each light fitting is equipped with this

„Installation and maintenance manual”, which must be kept by user until the end of exploitation.

•Light fittings are designed for fixed installations only.

•Using light fitting outside the designated operating temperature range is unacceptable and will

decrease a lifetime of light fitting and/or damage it. It will also cause a loss of warranty.

Remark: Using light fitting beyond the designated operating temperature range may reduce

its lifetime or damage to the luminaire itself.

•Each light fitting must have a warning sign: „DO NOT OPEN UNDER VOLTAGE” on it.

•As power cables, use 5-core cables (with PE core) or 7-core cables (with PE core) for the 3F

version.

•Use power wires with cross section 0,5-4mm2. Cross-section 2,5-6mm2 for special luminaire

execution.

•Maximum cross current I=16A. For 3 phase connection cross current I=10A

•Depending on the version, the diffuser is made of tempered glass or PC. Version with PC

diffuser should not be exposed to chemicals that can damage it, in particular: oil, acetone,

chlorine, ethyl, ether, solvents. If there is uncertainty about the substances present in the

luminaire's work area that could lead to damage to any of the components, then determination

measures should be taken. Luminaires fitted with a PC diffuser shall carry the warning label

"Caution! Risk of electrostatic charge".

•Do not stare into working light source.

•Risk of electrical shock.

9. LIGHT FITTING MAINTENANCE AND SERVICING

REMARK: during the servicing and maintenance touching the LED are prohibited, because it will

decrease the lifetime of light fitting and cause the loss of manufacturer’s warranty.

It is recommended to carry out inspections of electrical equipment in accordance with the

requirements of PN-EN 60079-17.