7 ATM Lighting sp. z o.o., ul. Budowlanych 31, 80-298 Gdańsk, tel: +48 58 347 51 07, fax: +48 58 347 51 08

INSPECTION: at least once a month. Inspection is made without opening the light fitting. User must

check admission cables condition (insulation damage, cracks, burns etc.). Cables must not have any

acute bends. Outside parts of the light fitting must be checked. No cracks or corrosion signs may occur.

Bolts used to mount light fitting should be properly tightened, washers mustn’t be cracked. Cleanliness

of outer surfaces and light fittings surroundings must be checked. Light fittings may not be soiled by

paint or grease. Do not allow for dust (dirt) deposition on the light fitting. The readability of rating and

warning plates must be checked. Abnormalities found must be fixed.

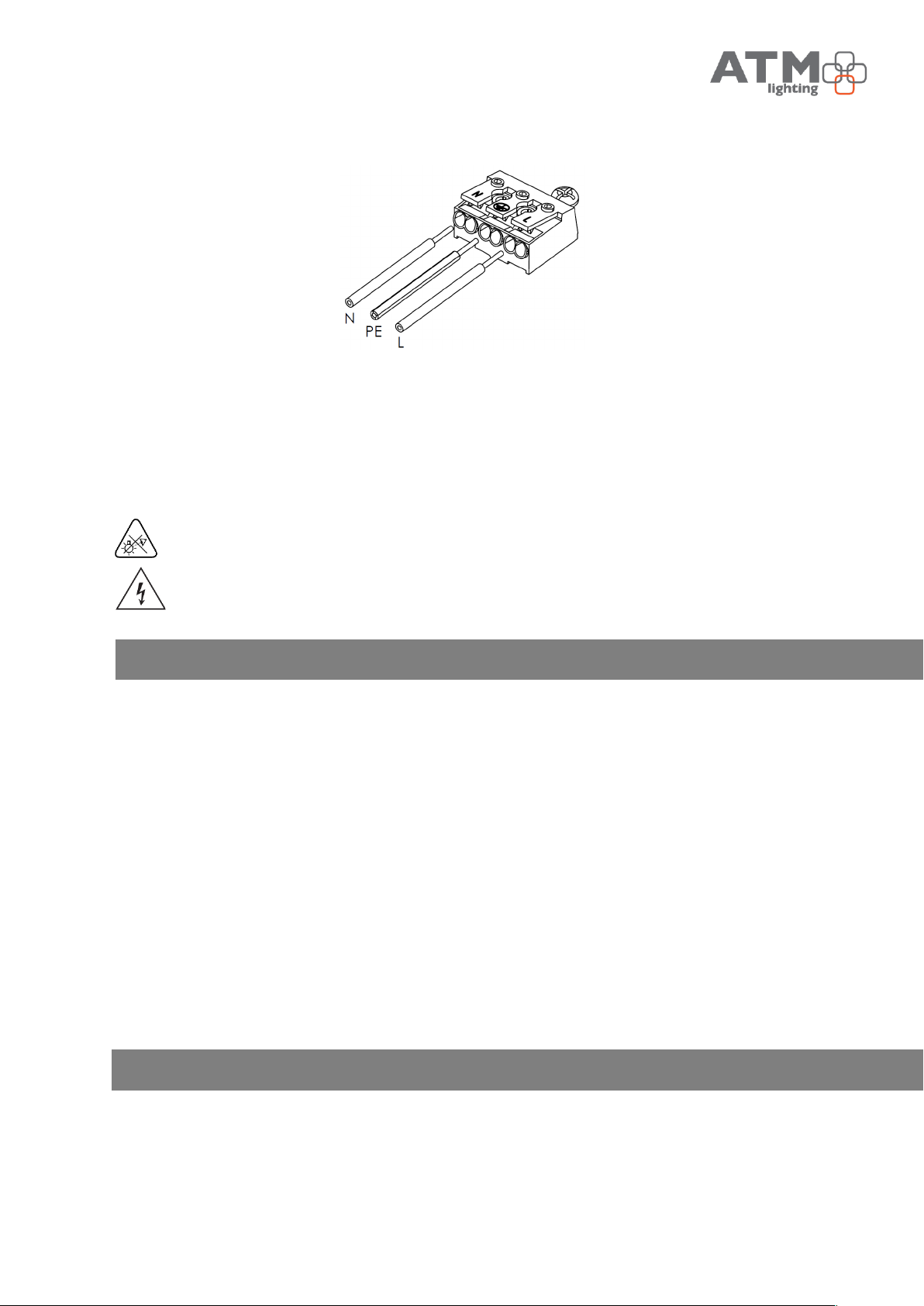

SERVICE AND MAINTENANCE: at least once a year. Service and maintenance must be made with

power supply turned off. User must make inspection steps first. After opening: metal parts painting,

condition of inner wiring and its mounting, insulating materials, cable glands gaskets, terminals.

Abnormalities found must be fixed. Rating and warning plates must be cleaned. Surfaces of insulating

materials and covers must be clean.

VERIFICATION OF TECHNICAL CONDITION: at least once for 2 years. Power supply must be

switched off. Light fitting must be uninstalled. Besides all the examination from inspection, service and

maintenance paragraphs electrical examination from the inspection, service and maintenance

paragraphs electrical examination must be also made: light fitting current consumption, insulation

examination, protective earthing condition. Special attention must be paid to insulating parts condition.

No crack or burns may occur.

CLEANING: do not allow for dust (dirt) deposition on the light fitting. Cleaning must be proceeded

without use of chemical. Cleaning must be proceeded with use of compressed air and soft cleaning cloth

or soft brush. If necessary use water and/or neutral detergent, however without any chemicals, which

can damage any part of the light fitting.

10. SPARE PARTS

All parts considered as a spare parts must be ordered at manufacturer of light fitting.

11. REPAIRING

All repairs may be made only by manufacturer or authorized repair workshops.

12. LIGHT SOURCE EXCHANGE

Lamps exchange may be made only by specially trained personnel using the original components

provided by ATM Lighting sp. z o.o.

13. TRANSPORT AND CONDITIONS OF STORAGE

During transport light fittings shouldn’t be exposed to precipitation or mechanical shock.

Light fittings may be storage only in sheltered warehouses, within +50C to +350C temperature range,

and relative humidity lower than 75%. No corrosion causing vapors or gases should be PRESENT.