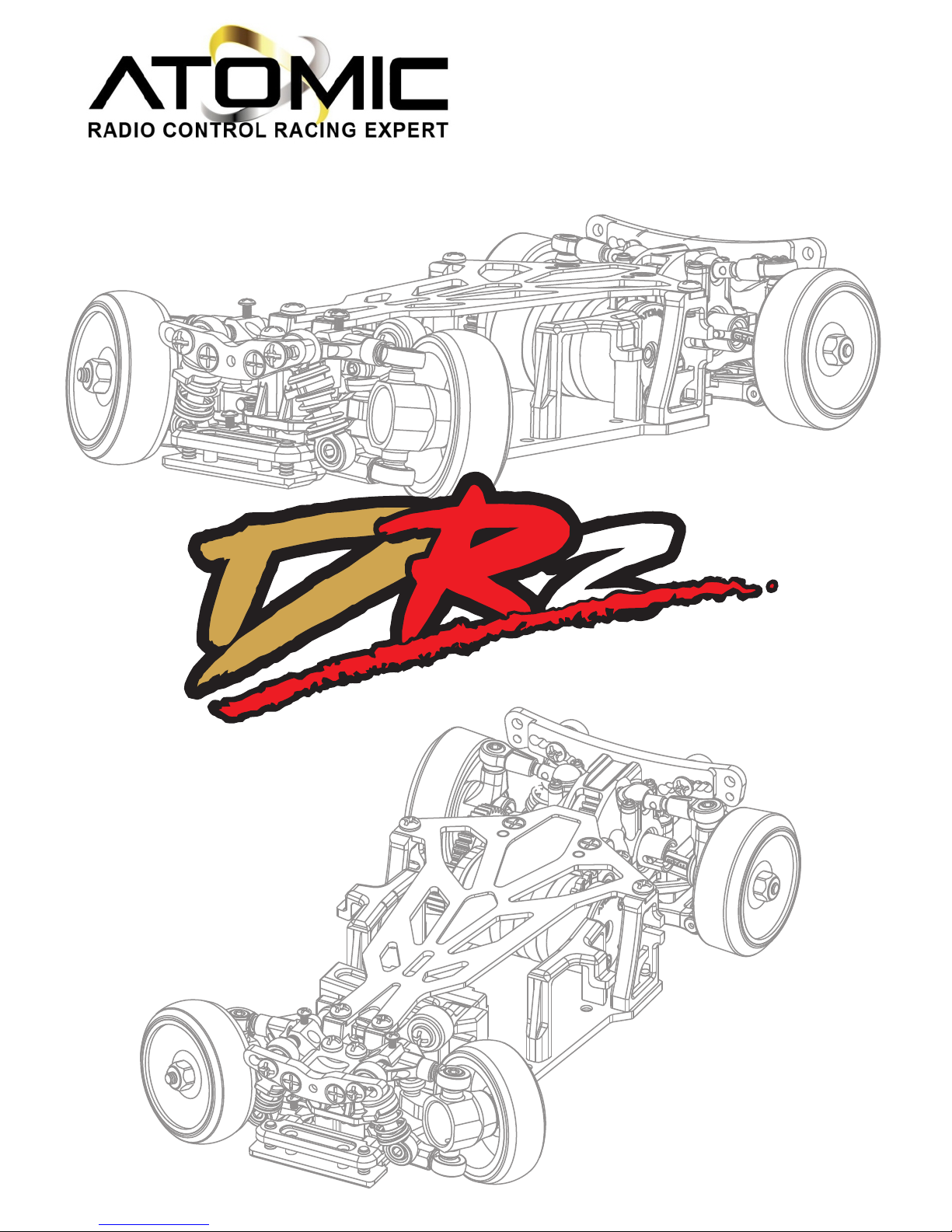

Atomic DRZ User manual

Other Atomic Motorized Toy Car manuals

Atomic

Atomic AMZ SERIES User manual

Atomic

Atomic BZ3 User manual

Atomic

Atomic FFZV2 User manual

Atomic

Atomic FFZ User manual

Atomic

Atomic BZ Evolution 2017 User manual

Atomic

Atomic DRZ2 User manual

Atomic

Atomic BZ Evolution 2017 User manual

Atomic

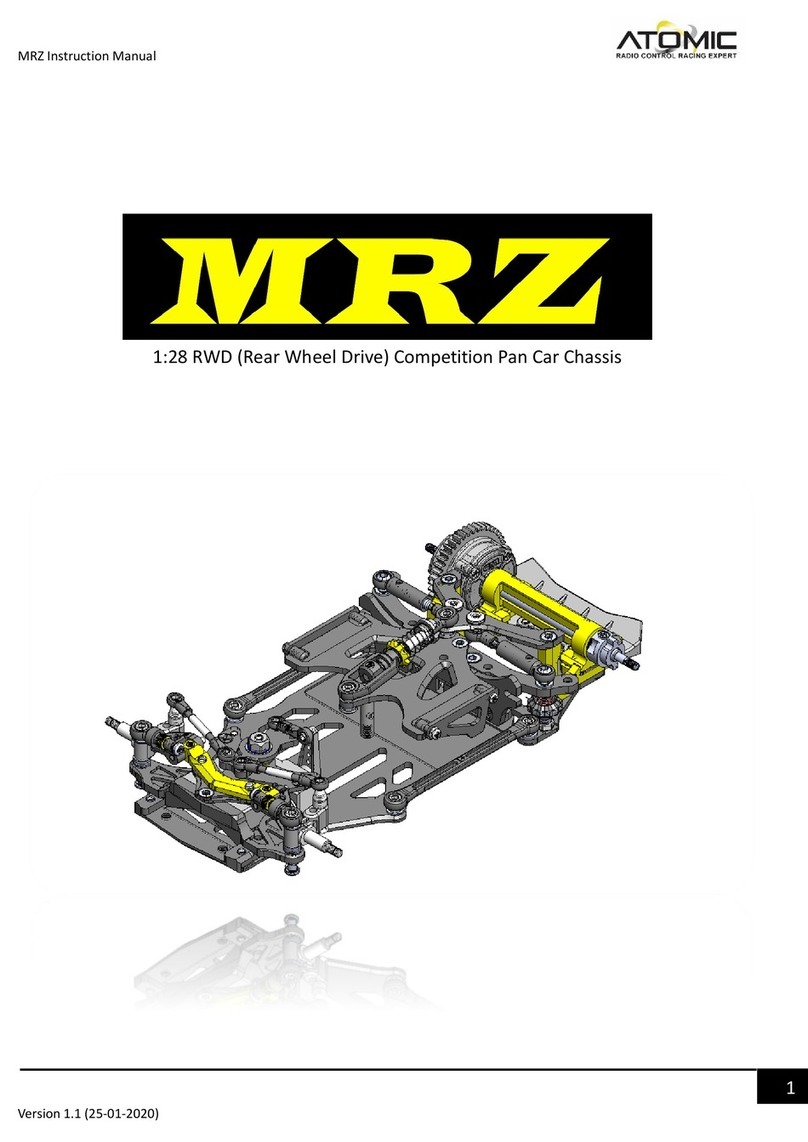

Atomic MRZ User manual

Atomic

Atomic DRZV2 Limited Edition User manual

Atomic

Atomic MRZ User manual