11/10/2008 1000-102-930 - INST

2

water/methanol, or any other mixture of water with combustible fluids, can

harm your vehicle's motor and the Water Boy components.Testing done by

ATS Diesel showed that injecting water/methanol causes a dangerous spike in

cylinder pressures. You can make more (and safer) power by adding fuel

through more aggressive E-Power Tuning and/or ATS Injectors/Fuel Systems

than you can by using water/methanol injection. The Water Boy can control the

increased EGT that would result from adding fuel.

DO NOT USE WATER/METHANOL WITH THE ATS WATER BOY

How the Water Boy Works

This kit is designed to progressively inject three stages of water. When the

system is armed with the power switch, the LED will be green. The first stage

activates when the EGT probe senses a temperature above the setting chosen

on the electronics box. A smaller "A" nozzle should be used for stage one if you

are using more than one size nozzle. When stage one is active, the LED will be

yellow. The second stage will activate when the EGT probe senses a

temperature above the setting for level two, AND approximately 10 psi of boost

or more (or 25 psi if the pink wire is not connected-See section below on Boost

Level Setting). The LED will change to Orange when Stage 2 is active (during

stage 2, the stage 1 nozzle will also be active). The third stage will activate when

the EGT probe senses a temperature above the box setting AND the boost

sensor measures approximately 15 psi (or 30-see Boost Level Setting section) of

boost or more. During stage 3, all three nozzles will be active and the LED will

be Red. When the tank is close to empty, the float switch will cut off supply power

to the pump. This will be indicated by a typical flickering of the LED. This will stop

pump “air-locking” which will help prevent the premature pump failure.

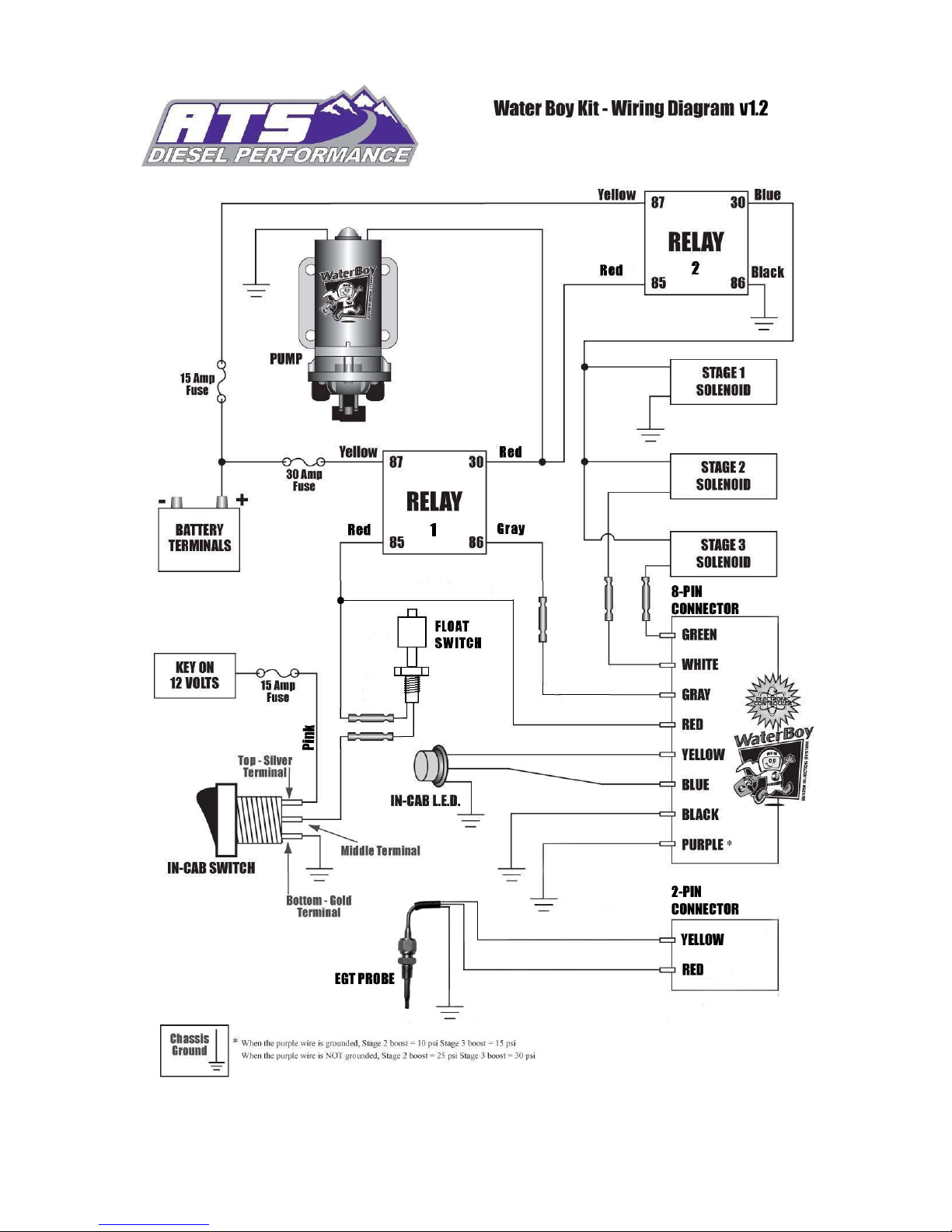

Boost Level Setting

In the Water Boy wiring harness, you will notice a purple wire. If you connect this

wire to a good ground the boost settings will be approximately 10 psi for stage 2

and 15 psi for stage 3. If this wire is not connected the boost setting will be

approximately 25 psi for stage 2 and 30 psi for stage 3. The harness is

assembled at ATS with the purple wire connected to ground. If the higher boost

levels are desired, then cut the purple wire. Choose the boost settings to suit

your vehicle’s performance. If the vehicle produces less than 35 psi of boost,

then use the lower settings.

Adjusting the Water Boy

The EGT settings at which each stage will activate can be adjusted to dial in the

Water Boy response to fit your needs and driving style. There are three small

Phillips head screws on the electronics board. Turning the screw counter-

clockwise will increase the temperature. Adjust the screws so that they will

activate progressively (stage one will be the lowest of the three temperatures).