MAN - PLC Lever Arm Tester - REV: 01

i

Manual Contents

A. Introduction..................................................................................................................... 1

A.1 Unpacking ....................................................................................................................................................1

A.2 After Sale Support .......................................................................................................................................1

B. Safety ............................................................................................................................... 2

B.1 For Owners, Operators, and Maintenance...................................................................................................2

B.2 Cautions.......................................................................................................................................................3

C. System Overview ............................................................................................................ 4

C.1 Safety Label Locations.................................................................................................................................4

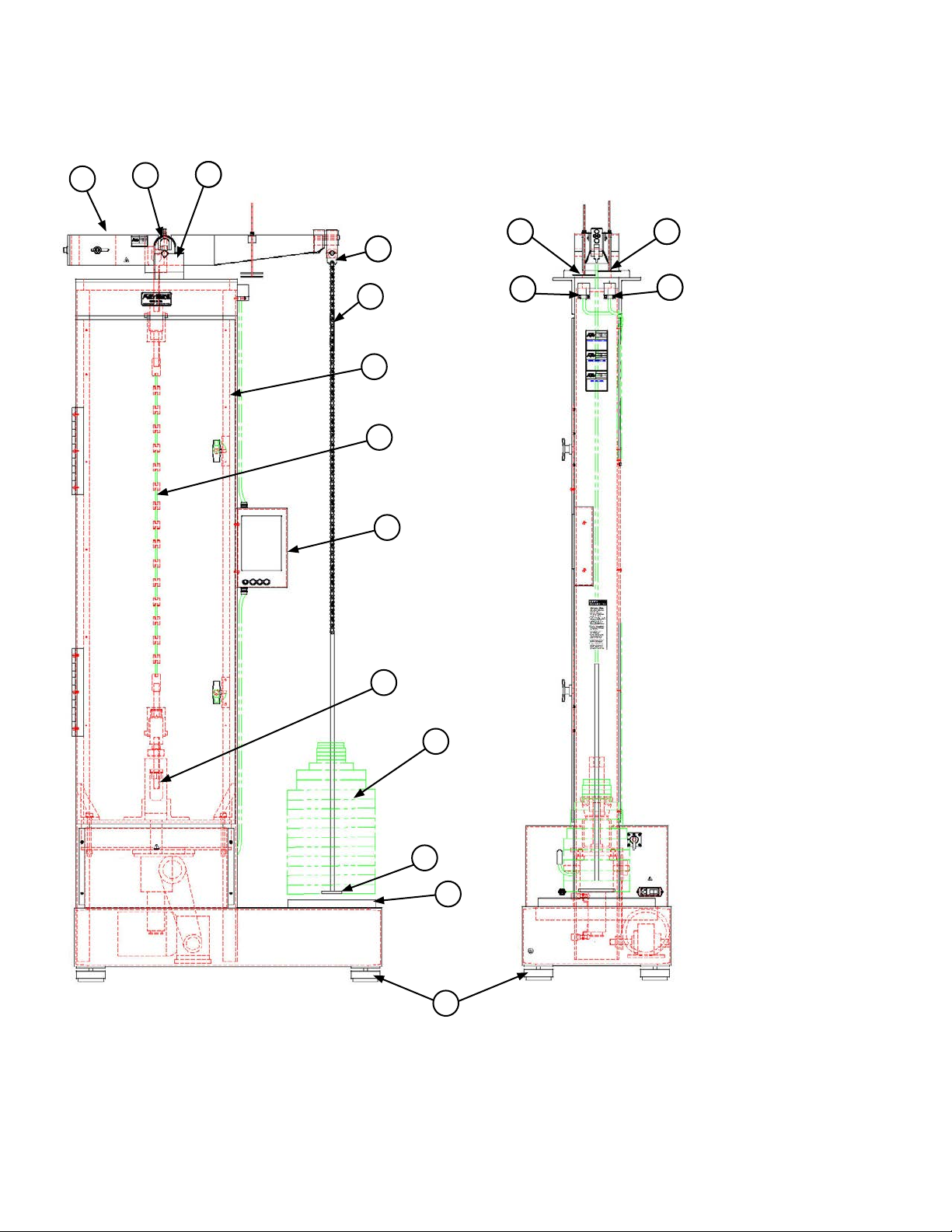

C.2 Equipment Parts ..........................................................................................................................................6

C.3 General Description.....................................................................................................................................7

Product Specications ...........................................................................................................................7

D. Installation ....................................................................................................................... 8

D.1 Unpack and Set Up ......................................................................................................................................8

D.2 Lever Arm Assembly Installation .................................................................................................................8

E. Software Overview........................................................................................................ 10

E.1 Main Screen ...............................................................................................................................................10

Process Time.......................................................................................................................................10

Unload Time.........................................................................................................................................10

Start Button..........................................................................................................................................10

View Button..........................................................................................................................................10

End/Stop Button................................................................................................................................... 11

O State............................................................................................................................................... 11

Running State ...................................................................................................................................... 11

Unload State ........................................................................................................................................ 11

Test Complete State............................................................................................................................. 12

Delay Start State.................................................................................................................................. 12

Sample Break State ............................................................................................................................. 12

E.2 View Screen...............................................................................................................................................12

Test Type.............................................................................................................................................. 13