1600 Series Universal Testing Machine

Instruction Manual

Table of Contents

Unpacking..................................................................................................................................................................................................4

Warranty ....................................................................................................................................................................................................4

After-sale Support......................................................................................................................................................................................4

Section 1. Safety .............................................................................................................................................................................5

For Owners, Operators, and Maintenance Staff........................................................................................................................................5

Warnings ..............................................................................................................................................................................................6

Cautions ...............................................................................................................................................................................................6

Section 2. System Overview............................................................................................................................................................7

General Description...................................................................................................................................................................................7

A. Specifications ............................................................................................................................................................................7

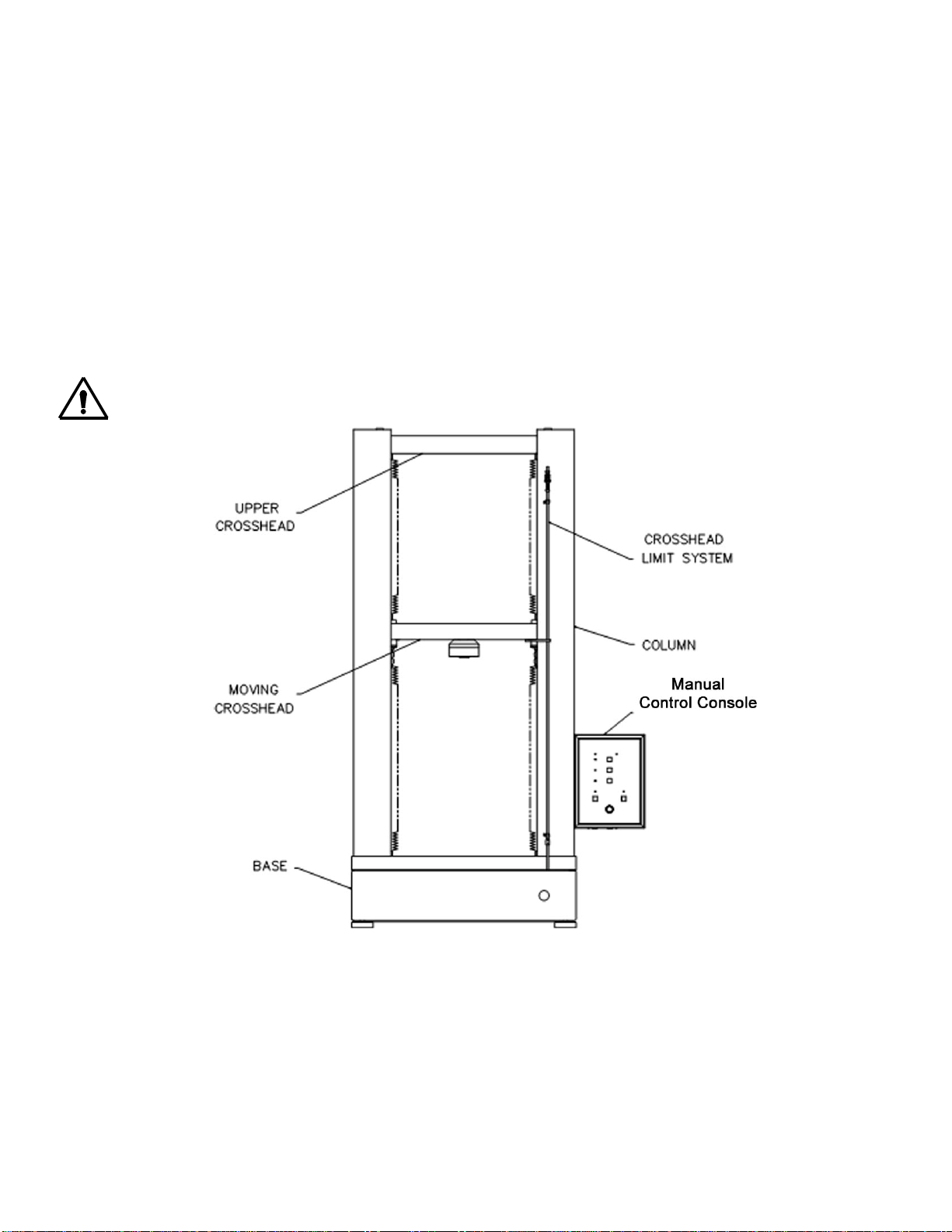

B. Load Frame ...............................................................................................................................................................................8

C. Personal Computer ...................................................................................................................................................................9

D. TestVue®Software ...................................................................................................................................................................9

E. Sequence of Operation .............................................................................................................................................................9

Section 3. Set-Up & Installation.....................................................................................................................................................10

General....................................................................................................................................................................................................10

Unpacking UTM Equipment.....................................................................................................................................................................10

Connecting Equipment ............................................................................................................................................................................10

Software Installation ................................................................................................................................................................................11

Updating Software ...................................................................................................................................................................................12

Attach Accessory Equipment...................................................................................................................................................................12

Accessing TestVue®...............................................................................................................................................................................12

Setting Hardware Parameters .................................................................................................................................................................13

Channel Set-up ..................................................................................................................................................................................13

Setting Software Preferences..................................................................................................................................................................20

Creating Graphs ......................................................................................................................................................................................21

Creating Reports .....................................................................................................................................................................................21

Pre-Set Information .................................................................................................................................................................................21

Options ....................................................................................................................................................................................................21

User Definition .........................................................................................................................................................................................22

Section 4. Controls ........................................................................................................................................................................24

Manual Controls ......................................................................................................................................................................................24

Computer Control Functions....................................................................................................................................................................25

Section 5. Operation......................................................................................................................................................................26

General....................................................................................................................................................................................................26

Creating a Test ........................................................................................................................................................................................26

Viewing Test Specifications.....................................................................................................................................................................32

Adding a Test Description to an Existing Test.........................................................................................................................................32

Positioning the Specimen ........................................................................................................................................................................33

Running a Test ........................................................................................................................................................................................33

Manual Control...................................................................................................................................................................................39

Section 6. Obtaining Results .........................................................................................................................................................41

General....................................................................................................................................................................................................41

Generating a Report ................................................................................................................................................................................41

Printing a Report......................................................................................................................................................................................42

Creating a Report ....................................................................................................................................................................................42

Opening a Report in Microsoft Word .......................................................................................................................................................45

Generating a Graph.................................................................................................................................................................................45

Creating a Graph .....................................................................................................................................................................................47

Zooming In On a Graph...........................................................................................................................................................................48

Exporting Data to ASCII File....................................................................................................................................................................48

Section 7. Maintenance .................................................................................................................................................................51

Maintenance ............................................................................................................................................................................................51