2

Copyright

The design of this product (includingsoware) and its accessories is under tutelage of laws. Any

to violate relevant right of our product will be penalized through law. Please consciously

observe relevant local laws in the use of this product.

Symbolsand conven�ons

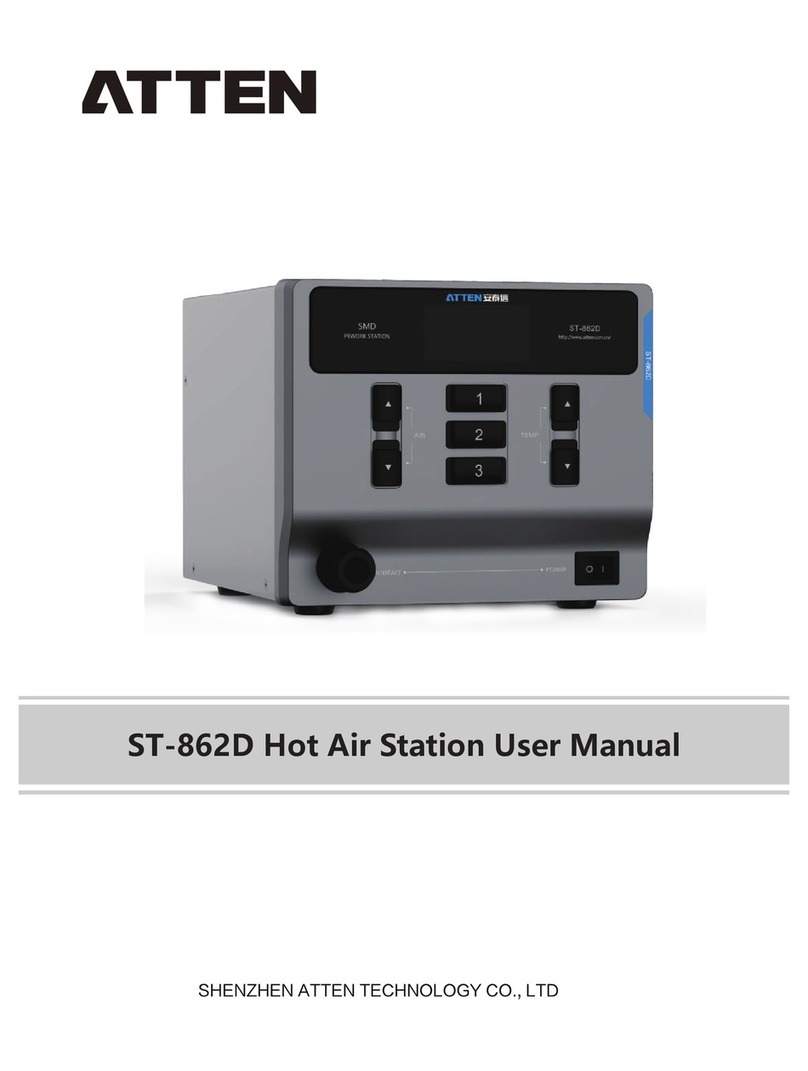

Thank you for purchasing this soldering staon product. Please read this manual carefully and pay

aenon to warnings and prec mened herein before using this product.

Warning you against therisk of electric shock.

Warning you against therisk of physical injury.

Assump�on for user

We assume that user have common sense and basic relevant electrical opera knowledge before

using this product. This device is not intended for use by persons (including children) with limited

physical, sensory or mental ape, or by persons who lack knowledge or experience in handling

the device. This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental ca or lack of experience and knowledge if they

have been given supervision or instr concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

Safety

Disclaimer

For physical injuries and possessions loss caused by those reasons which are not related to

product quality such as opera without following manual guide, natural disasters or force

majeure, we take no responsibility for that.

Under the supervision of Shenzhen Aen Technology Co., Ltd, this manual has been compiled

and published which covered the latest product and ca The content of

WARNING: The soldering temperature can reach 150 ~480 as this product in working

status. User shouldobey following rules rigorously in view of improper opera will causeres or

burns.

Never touch soldering and surrounding metal part of soldering before soldering

cool down completely.

Never usethis product around objects.

Always turn switch oaer operan and always turn switch ofor temporary

notopera

User must w soldering iron cool down completely aer turning switch ofor the

replacement of soldering and internal parts.

Never operate on product for those who have no experience or have no basic knowledge for

the circumstance of no guidance.

Keep this product out of reach of children.

Never place product and part of it in water or operate as your hands are wet.

Please keep workplace well venated for fumes produced in soldering work.

Never play with others while using this product.