AU Tool LM120 Plus User manual

www.autooltech.com

AUTOOL LM120+

Digital Manifold Gauge

User Manual

All rights reserved! Without the written approval of Shenzhen AUTOOL

Technology Co., Ltd., no company or individual may copy or back up this

manual in any form (electronic, mechanical, photocopying, recording, or

other forms). This manual is specially designed for the products of AUTOOL,

and our company will not be liable to the consequences caused by using this

manual as the operation instructions for other equipments.

If the device is damaged or lost owing to accident caused by the user or a

third party, abuse, misuse, unauthorized modification or random repair of the

device, or failure to follow the operation and maintenance requirements of

AUTOOL, our company and its branches will not be liable to any cost

caused by these conditions.

Formal statement: The other product names mentioned in this manual are

used to explain how to use this device, and the registered trademark still

belongs to the original mark owner.

This equipment is designed for professional technicians or maintenance

workers.

Trademark

AUTOOL Technology Co, Ltd. has registered its trademark in many different

countries, the trademark is AUTOOL. Any other trademark, service logo,

domain name, icon or company name mentioned in this manual belongs to

AUTOOL and its affiliated companies. In those countries where the

trademark, service logo, domain name, icon and company name of AUTOOL

has not been registered yet, we declare that they belong to AUTOOL. Any

company or person shall not use the trademark, service logo, domain name,

icon or company name of AUTOOL before getting the written approval of

AUTOOL. Please visit our website www.autooltech.com or contact us at

1.Overview

Intelligent electronic refrigerant group instrument is an auxiliary instrument

for the installation, testing and maintenance of refrigeration equipment such

as air conditioners and cold storage. The instrument has double pressure

test, dual temperature test, digital readout, multi- unit switching, multi-mode

function and built-in refrigerant database.

The instrument uses high-strength engineering plastics and flexible non-slip

silicone design, the whole machine is solid and comfortable to hold. Built-in

32-bit digital processing unit and high-precision data acquisition unit, high

data and stability. Large-size liquid crystal display, LCD backlight support,

data display clear and easy to read, convenient light operation. Long-life

valve switch, 1/4-inch standard interface design to ensure that the

instrument's durability and versatility.

The instrument can measure double pressure (gauge pressure) at the same

time, as well as dual temperature measurement, with automatic multi-unit

pressure conversion, automatic conversion of temperature Celsius /

Fahrenheit, to facilitate different needs. Built-in 89 kinds of refrigerant

pressure-evaporation temperature database, also calculate the subcooling

superheat, to facilitate direct reading of operating process data. Also it tests

percentage of vacuum measurement; pressure leak measurement, leak

time speed record. It is deserved to have this multi- functional, accurate and

simply operated digital manifold let you do the job right.

2.Safety rules and precautions

This manual includes the use of instrument instructions and warnings for

safe operation and maintenance. Failure to use the meter in accordance

with the manual may damage the instrument. This instrument strictly follows

the IEC/EN61010-1 safety standards for design and production.

1) The pressure measured by the digtal manifold pressure tester is gauge

pressure.

2) Pressure testing ranges from -101Kpa to 6Mpa (- 0.1bar to 60bar).

3) The limit pressure is 10 Mpa (100 bar).

1

4) The maximum operating pressure of standard hose is 600 PSI

( approximate 4.13 Mpa, 41.3 bar ). The limit pressure is 3000 PSI

approximate 20.68 Mpa, 206.8 bar ).

5) Please confirm the rated pressure value of the tested equipment before

testing. Do not use it if it exceeds the range of the instrument. If the packed

hoses does not match the pressure requirement, you can use suitable

replacements for testing.

6) Do not use and store the instrument in high temperature, high humidity,

flammable, explosive and strong electromagnetic fields.

7) Please do not change the instrument internal circuit, to avoid any

damage of the instrument or danger occurring.

8) Please wear qualified protective equipment to protect user during testing.

Please use the instrument in a well-ventilated environment to prevent

inhalation of toxic gases.

3.International electrical symbols

4.Product specifications

Pressure test: gauge pressure

Pressure test unit: Kpa; Mpa; bar; inHg; PSI. Pressure test range: 0 Kpa –

6000 Kpa Pressure test resolution: 1 Kpa

Pressure test accuracy: +/- 0.5 %(FS)+ 5dgt

Pressure overload limit: 10000 Kpa (10 Mpa; 100 bar;)

DC

AC

DC/AC

warning

dangerous voltage(electric shock)

earth

double insulation

fuse

battery

2

Vacuum test: relative vacuum

Vacuum test unit: Kpa; Mpa; bar; inHg; PSI. Vacuum test range: -101 Kpa –

0 Kpa Vacuum test resolution: 1 Kpa

Temperature test unit: °C (Celsius), °F (Fahrenheit) Temperature test range:

-40°C–150°C (-40°F–302°F) Temperature test resolution:

0.1°C (-40°C–99.9°C), 1°C (100°C–150°C)

0.1°F (-40°F–99.9°F), 1°F (100°F–302°F)

Temperature test accuracy: +/- 0.5 °C + 2dgt

+/- 0.9 °F + 2dgt Built-in 89 kinds of refrigerant NIST:

According to American NIST standard

Power Supply: 4 X 1.5V (SIZE.AA / LR6) Dimensions: 170* 110* 50mm

weight: 950g

R11 R113 R114 R115 R116 R12 R123 R124 R125 R1270

R13 R134A R14 R141B R142B R143A R 1 5 2 A R170 R21 R218

R22 R227EA R23 R236EA R245CA R245FA R 2 9 0 R 3 2 R 4 0 1 A R 4 0 1 B

R401C R402A R402B R403A R403B R404A R405A R406A R407A R407B

R407C R 4 0 7 D R407E R 4 0 8 A R 4 0 9 A R 4 0 9 B R 4 1 R 4 1 0 A R 4 1 0 B R 4 1 1 A

R411B R 4 1 2 A R413A R 4 1 4 A R 4 1 4 B R 4 1 5 A R415B R416A R417A R418A

R419A R 4 2 0 A R421A R 4 2 1 B R 4 2 2 A R 4 2 2 B R422C R422D R423A R424A

R425A R426A R427A R428A R50 R500 R501 R502 R503 R504

R507A R 5 0 8 A R508B R 5 0 9 A R 6 0 0 R 6 0 0 A R 717 R744

(Co2) R1234

3

5.Product Icon and description

1) Clamp-on temperature probe socket.

2) Clamp-on temperature probe socket.

3) LCD display.

4) Run/Stop button: In Leak Test Mode, Test Control Button.

5) Function button: test function mode switch button.

6) R+/R-Refrigerant Type Selection Buttons: Switch to select different types

of working refrigerants.

7) Unit button: pressure unit switch button.

8) °C/°F button: temperature unit switch button.

9) Zero button: pressure display zero button.

10) Backlit button.

11) Power button.

12) Refrigerant observation window.

13) Low pressure valve.

14) High pressure valve.

15) 1/4 inch low pressure inlet.

16) 1/4 inch high pressure inlet.

17) Pressure release valve.

18) Refrigerant inlet/vacuum pump inlet.

4

6.Function instructions

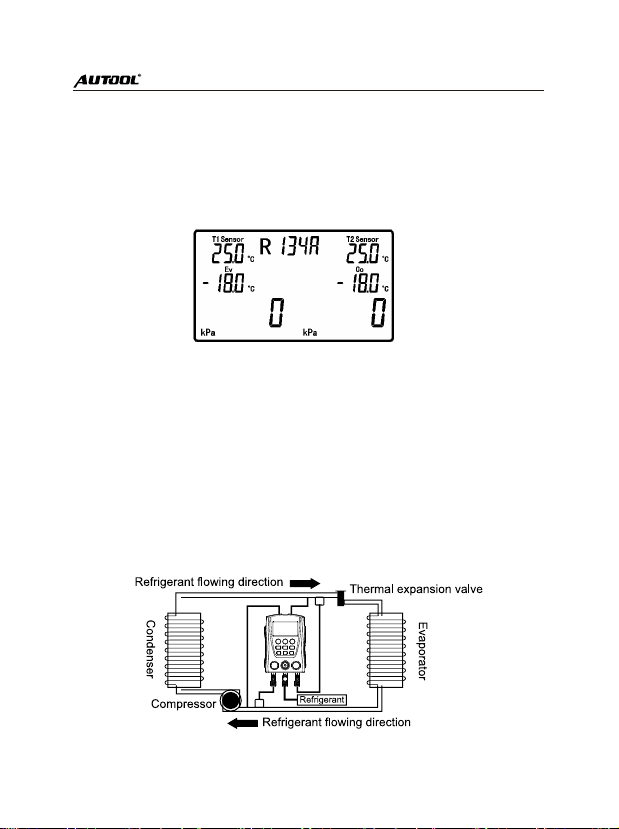

6.1 Refrigerant filling and pressure inspection

A. Turn off the blue valve and red valve.

B. Power on the instrument. Then make sure if the LCD displays pressure

test status as below picture. If not, press the Function button to switch it.

C. If the temperature probe accessories have been connected to the

instrument, the real-time temperature will be displayed. If not, no display of

it.

D. Press R+/ R- buttons , Unit button and °C/°F button to select tested

refrigerant and reading display respectively.

E. When the instrument is turned on, there may be 10 digits in the high and

low pressure display area. At this time, press the zero button long until it

returns to zero.

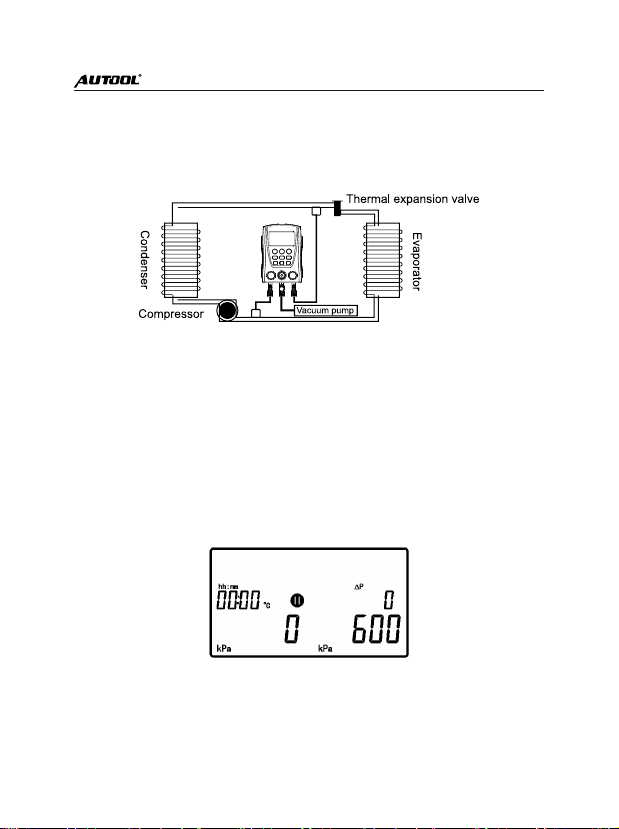

F. Connect the instrument to the refrigeration system according to the chart

below. (pay attention to the direction of the refrigerant flowing !!!!! )

5

G. Turn on the refrigerant valve and gently press the pressure release

valve to vent the air in the connecting hose.

H. When the refrigeration system stops, turn on the high pressure valve

(red valve) and fill with a certain amount of refrigerant and then shut the

valve quickly.

I. Run the refrigeration system, turn on the low pressure valve (blue

valve), and fill with the refrigerant into the refrigeration system. Vacuum

operation is required if it is filled initially or in full with refrigerant. Refer to the

section on vacuum operation.

J. After the filling is completed, shut the low pressure valve (blue valve) and

refrigerant valve. Let the refrigeration system running.

K. Shut down the refrigeration system, make sure all valves are turned off ,

then disconnect the instrument between refrigeration system and source.

Do not remove the high pressure valve connection until the pressure drops

to the safe point. Then turn off the instrument.

Note: The filling operation of different equipment or refrigerants may vary.

Please read carefully the relevant specific operation requirements for filling

operation, so as to avoid damage to user or equipment caused by improper

operation! ! !

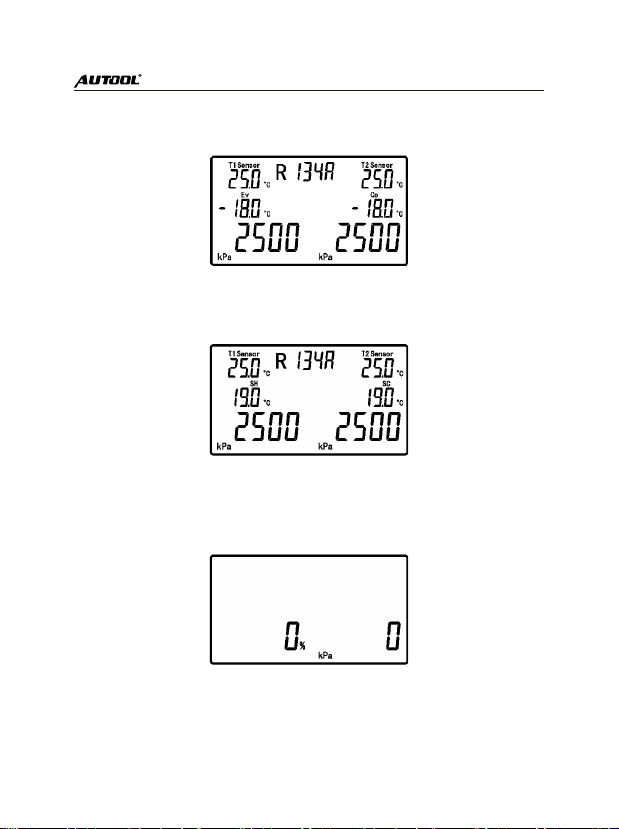

◆ The instrument can display the corresponding Evaporation Temperature

(EV) and Condensation Temperature (CO) during the refrigerant pressure

test, as shown below:

◆ If the clamp-on temperature probes are connected to the instrument,

LCD will display the real-time temperature in the spot T1 Sensor and T2

Sensor, as shown below.

6

Please make sure clamp-on temperature probes are connected as step F

and contacted fully to the refrigeration pipes.

◆ The instrument can calculate the SH - Superheat and SC - Subcooling

as shown below as long as the tested refrigerant is preset and clamp-on

temperature probes are connected well.

6.2. Vacuum operation

A. Turn off the blue valve and red valve.

B. Power on the instrument. Then make sure if the LCD displays vacuum

test status as below picture. If not, press the Function button to switch it.

C. Press the unit button to adjust the reading unit.

D. When the instrument is turned on, there may be 10 digits in the high and

low pressure display area. At this time, press the zero button long until it

7

E. Connect the instrument to the refrigeration system according to the chart

below. (pay attention to the direction of the refrigerant flowing!!!!! )

(Connected clamp-on temperature probes will not affect the operation..)

returns to zero.

F. Turn on the blue valve and red valve, and start the vacuum pump.

G. After the vacuum operation is completed, turn off the blue valve and red

valve, then shut the vacuum pump.

H. At this time, pressure leak test mode can be used to check leakage in

the system ( Please refer to 6-3. Pressure Leak Test).

6-3. Pressure Leak Test

A. The instrument is power on with the blue and red valves turned off.

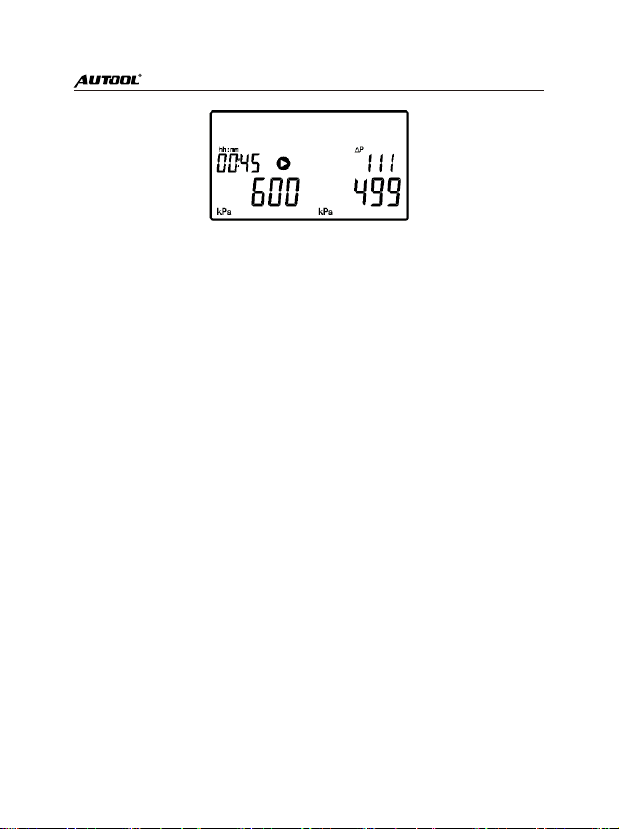

B. Press the Function button to pressure leak test mode shown as below.

The current pressure value is displayed at lower right corner of LCD.

C. Press the Run/Stop button to start the leak test, as shown below:

8

At this time, the lower left corner records the initial pressure value; the

lower right corner shows the instantaneous pressure value; the “ΔP” display

area shows the difference between initial pressure value and instantaneous

pressure value.

The time display area shows how long the leak test lasts in the format of

Hour : Minute (HH:MM). All the pressure units on the screen are the same.

You can switch different pressure units by pressing the unit button.

7. Common problems

7-1. Low battery power supply

The instruments has low power sign. When it is displayed , it means the

battery power is insufficient. At this time, the battery should be replaced as

required in order to avoid affecting normal use.

7-2. Damaged refrigerant hose or valve stem

Please check the pipe fittings and the hoses before testing. Once any

damage is found , please replace it immediately to avoid improper use or

any accident occurring.

7-3. Failure of refrigerant filling

There is a valve core in the refrigerant inlet of the refrigeration system.

When connecting the instrument, pay attention to the two terminals of the

hoses. Connect one terminal with a core to the refrigeration system, while

another terminal without a core to the instrument.

7-4. Potential leak points

Every hose terminal comes with a nylon pad that is limited a certain life of

using. Over use or other situation will make it defective, which result in

leakage.

9

The instrument refrigerant inlet (the middle port of the instrument ) has a

port with valve core , which is used to vent the air in the hoes after

connecting the refrigerant to the instrument.

The port is equipped with a copper plug screw. It is required to tighten it

every time before or after operation.

Check the refrigeration system's pipes and connectors.

8. Glossary

Saturation

The state of saturation is the coexistence of a refrigerant in a liquid and gas

state.

Condensation temperature and evaporation temperature

Condensation temperature: in the condenser, the refrigerant is condensed

by the high-temperature gaseous refrigerant to the temperature of the liquid

refrigerant, that is, the saturation temperature under the condensing

pressure.

Evaporation temperature: in the evaporator, the refrigerant evaporates from

the liquid refrigerant to the temperature of the gaseous refrigerant, that is,

the saturation temperature under the evaporation pressure.

Degree of subcooling and superheat

Subcooling: condensing temperature - condensing outlet temperature.

Superheat: evaporation outlet temperature - evaporation temperature.

The lower subcooling can make the refrigeration capacity of the system

better. Adding subcooling circuit and economizer in the refrigeration system

is to increase the subcooling for refrigerant increasing.

Every hose terminal comes with a nylon pad that is limited a certain life of

using. Over use or other situation will make it defective, which result in

leakage.

The degree of expansion of the expansion valve (refrigerant charge) affects

the degree of superheat. The greater the degree of superheat, the smaller

the opening of the expansion valve can be determined (the refrigerant

charge is less).

10

Sensible heat and latent heat

The amount of heat required to raise the water temperature from 0 degrees

to 100 degrees is sensible heat, the water is heated to 100 degrees, and the

hot water becomes water vapor, but the temperature is still 100 degrees.

The heat required for this process is called latent heat.

Gauge pressure and absolute pressure

Gauge pressure: Gauge pressure refers to the pipeline pressure, refers to

the pressure measured by pressure gauges, vacuum gauges, U-shaped

tubes, etc., also known as relative pressure. The “table pressure” starts with

atmospheric pressure and the symbol is Pg.

Absolute pressure: The pressure directly acting on the surface of a container

or object is called "absolute pressure", the absolute pressure value is

absolute vacuum as a starting point, the symbol is PABS (ABS is a

subscript) and the absolute pressure is atmospheric pressure + gauge

pressure.

At atmospheric pressure, the gauge pressure is 0 and the absolute pressure

is 1.013 bar.

Dry bulb temperature, wet bulb temperature and black ball temperature

Dry bulb temperature: the temperature measured by ordinary thermometers.

Wet bulb temperature: a wet cloth is wrapped around the thermometer, and

the temperature indicates a drop due to the evaporation of water. The

temperature at this time is called the wet-bulb temperature.

11

After-sale Service

Warranty

We offer repair service or replacement according to the specific type of the

fault.

We guarantee that all the parts, accessories and device for replacement are

brand new.

AUTOOL will bear the shipping cost and offer the corresponding

accessories for replacement without charge if the customer sends us video

and pictures of the product that fails within 90days after receipt.

If the product has been received for more than 90 days, we will provide the

spare parts for replacement without charge but the buyer is supposed to

bear the other relevant costs.

The warranty is void if the product is:

* Bought through non-official channel;

* Damaged because of improper use or maintenance not following the

user manual;

Declaration

Please note that AUTOOL reserves the right to change product designs and

specifications without notice. Images or descriptions in this manual are for

illustration purposes only. Actual products may vary in terms of appearance

and color. We are always trying to offer an accurate user manual, but we

can hardly guarantee that there is absolutely no difference. The right of the

final interpretation of the products belongs to AUTOOL, and we will not be

liable to any loss or damage caused by misunderstanding.

12

Table of contents

Other AU Tool Measuring Instrument manuals

AU Tool

AU Tool X90 User manual

AU Tool

AU Tool X91 TPMS User manual

AU Tool

AU Tool BT60 User manual

AU Tool

AU Tool X60 User manual

AU Tool

AU Tool LM110 User manual

AU Tool

AU Tool X90 User manual

AU Tool

AU Tool SDT 206 User manual

AU Tool

AU Tool X50 Plus User manual

AU Tool

AU Tool X60 User manual

AU Tool

AU Tool X50 PRO User manual