Au3Tech C4 User manual

C4 Cutting head Users Manual

By Au3tech Research Pty Ltd

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

2

Introduction

Overview

This document mainly describes the appearance, application scenarios,

installation, debugging, operation, maintenance, etc of C4 fiber laser

process head.

Reader Objects

This document mainly is applicable to the following personnel:

•Installation engineers

•Maintenance engineers

•Operators

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

3

Table of Content

Introduction....................................................................................................................................2

Table of content .............................................................................................................................2

1 Overview ......................................................................................................................................4

1.1 Product Overview.......................................................................................................................4

1.2 Products feature.........................................................................................................................5

1.3 Cutting head parameters...........................................................................................................5

2 Structure Specifications.............................................................................................................6

2.1 C4 Fiber laser cutting head brief................................................................................................6

2.1.1 C4 flatbed cutting head...........................................................................................................6

2.1.2 C4 3D cutting head.................................................................................................................7

2.1.3 C4 fine cutting head................................................................................................................8

3 Installations.................................................................................................................................9

3.1 Pre-installation preparation........................................................................................................9

3.2.1 C4-QBH100-F125 and C4-QBH100-F150........................................................................10

3.2.2 C4-3D-QBH100-F125 .......................................................................................................11

3.2.3 C4-FC-QBH100-F50.........................................................................................................12

3.4 QBH Connection......................................................................................................................14

4 Focus Adjustments...................................................................................................................15

4.1 Focus centering .......................................................................................................................15

4.2 Z position adjustments.............................................................................................................16

5 Operation &Maintenance..........................................................................................................17

5.2 Collimator and focus lens maintain..........................................................................................19

5.2.1 Take out of lens holder.........................................................................................................19

5.2.2 Assemble the lens holder .....................................................................................................19

6 Technical Indexes.....................................................................................................................21

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

4

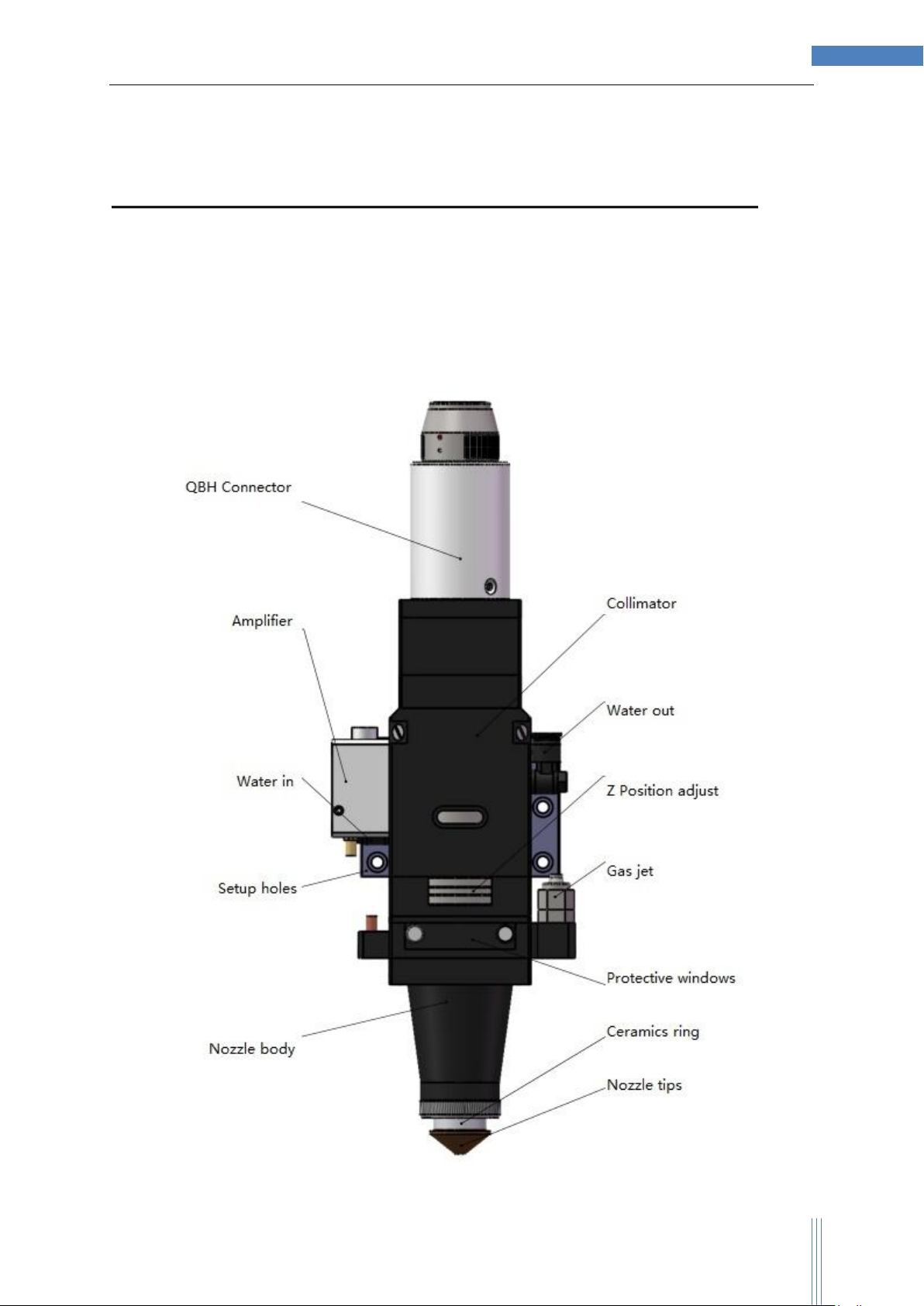

1Overview

1.1 Product Overview

C4 series flat-bed cutting head is a kind of fiber laser cutting head suitable for median to high

power. It can cut stainless steel of maximum thickness 7 mm and carbon steel of maximum

thickness 15 mm with best cutting quality. It features with water cooling and draw design for

protective windows. Fiber interface is available with only QBH connector. Best support 1000W to

2000W application.

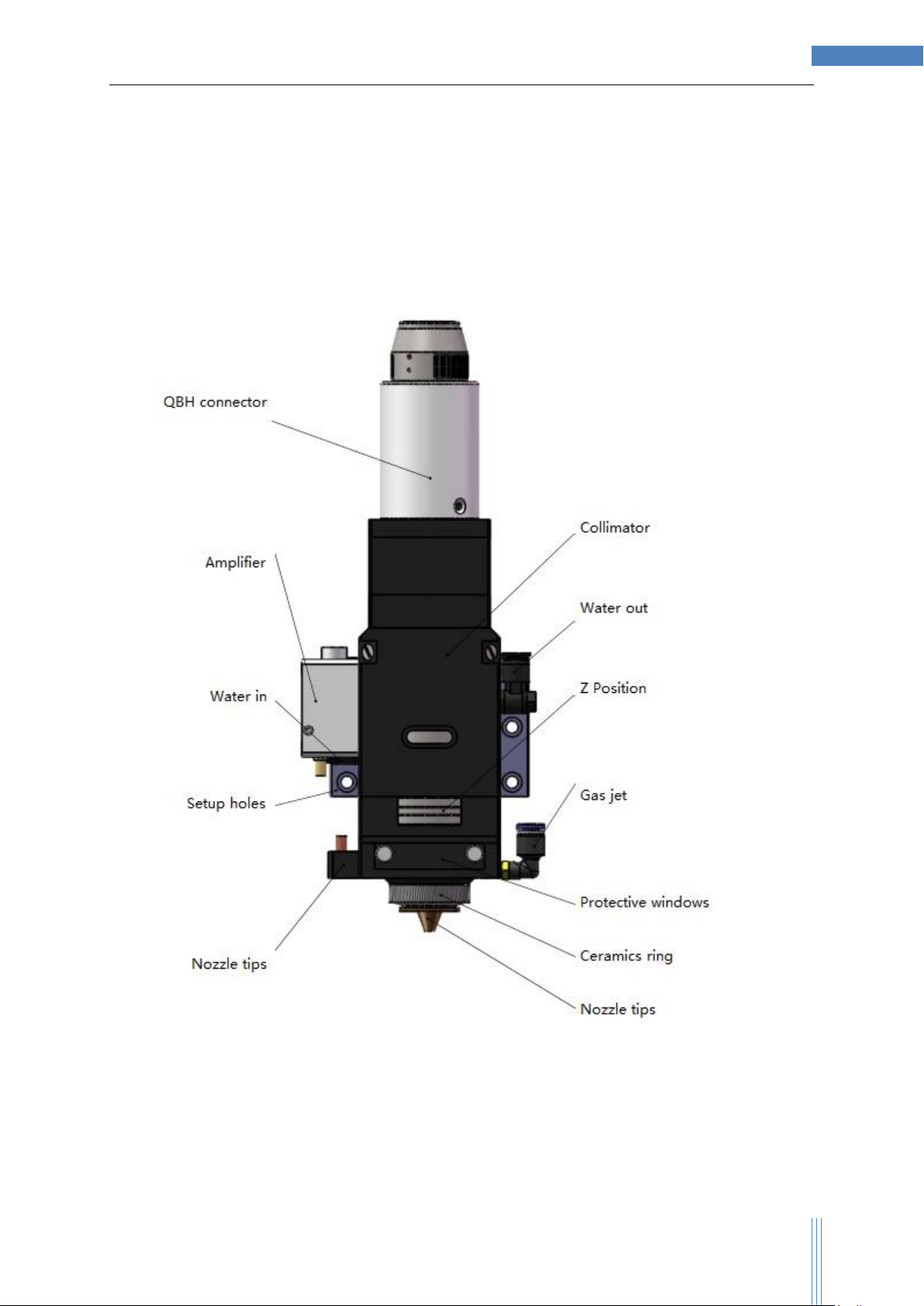

Fiure1-1 Product Appearance

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

5

1.2 Product Features

Support multiple kinds of focal length (125mm, 150mm)

Support multiple kinds of fire-optic link (QBH, QD)

Focus module design with high-precision

Centering control module design with precision

Protection lens box can be quickly disassembled

Optimized smooth gas circuit design; multiple kinds of auxiliary gases; the maximum

atmosphere pressure can reach 2.5MPa

1.3 Cutting head parameters

Since different cutting heads have different focal lengths and optical chucks, the following

parameters are described with chuck QBH and focal lengths 125mm as an object. For other

configuration parameters, please connect the technical engineers ofAut3tech.

Maximum power

1500W

Focal length

125mm, 150mm

Collimation focal length

75mm, 100mm

Diameter of focus lens

30mm

Nozzle aperture

1mm to 3mm

Length of cutting head

341mm@FL=125mm

Weight

2.6KG@FL=125mm

Maximum atmosphere pressure of auxiliary gas

2.5MPa

Maximum outer diameter

64mm

Available focusing ranges

-6mm to +9mm

Type of optical fiber splice

QBH

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

6

2Structure Specifications

2.1 C4 Fiber laser cutting head brief

C4 fiber laser cutting are designed for flatbed cutting, 3D cutting and fine cutting.

2.1.1 C4 flatbed cutting head

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

7

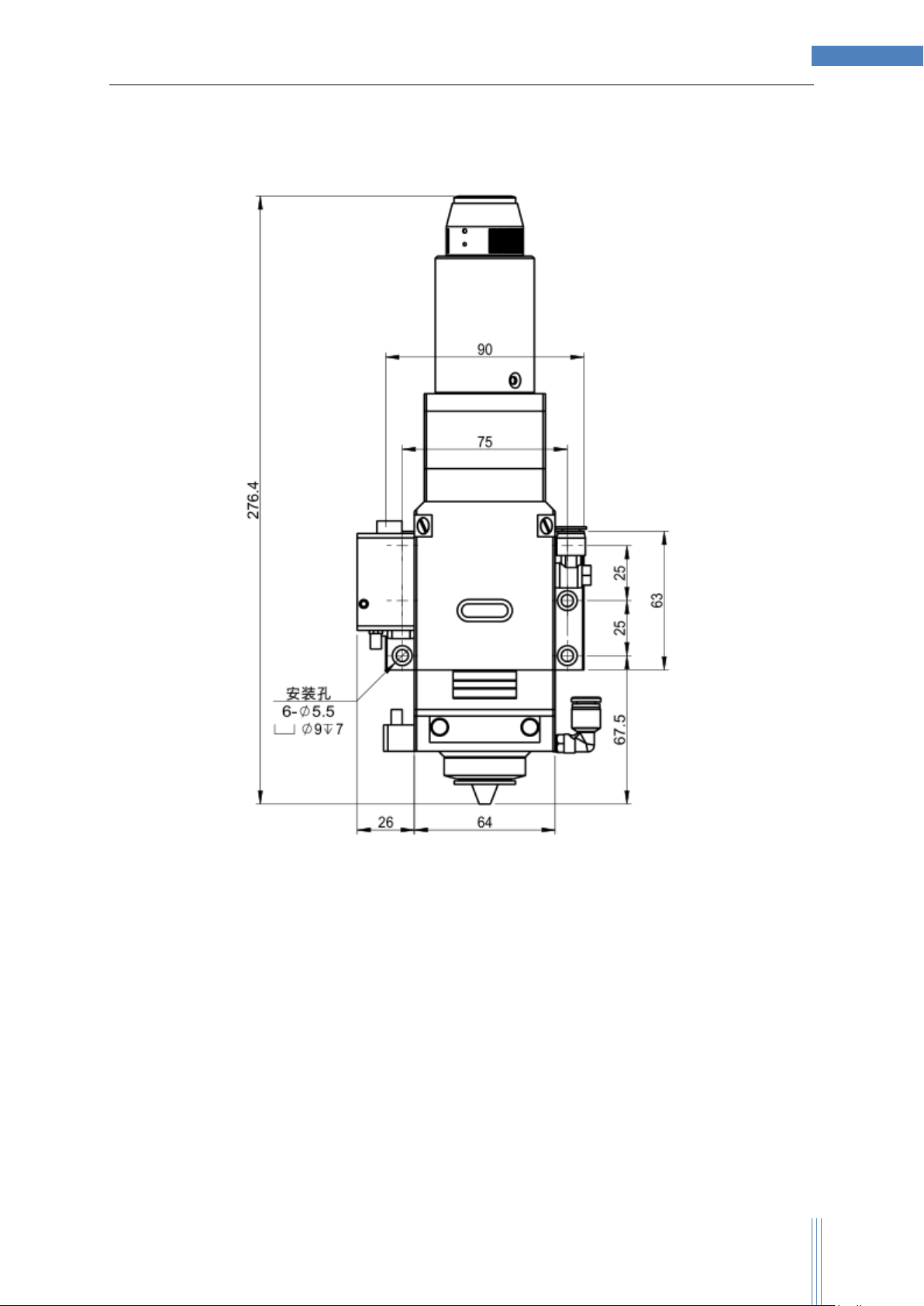

2.1.2 C4 3D cutting head

C4 3D series is designed for 3D cutting. It comes with longer focus length than normal flat-bed

cutting heads. In term of larger aperture and longer focus length, the depth of focus can achieve

longer than usual, so the cutting curve can be better quality. The tip of the head is small and

straight for 3D or tube cutting.

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

8

2.1.3 C4 fine cutting head

C4-FC series is designed for fine cutting. It comes with shorter focus length than normal flat-bed

cutting heads or 3D cutting heads. In term of larger aperture and short focus length, the focus

spot can achieve smaller and it is better for thin metal cutting.

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

9

3Installations

3.1 Pre-installation preparation

Before installing C4 cutting head, please ensure fiber-optic chuck is sealed and during

installation, never remove sealing.

Table 3-1 List of Tool Preparation

Name of Tool

Picture

Main Functions

No.3 socket head

wrench

Backboard of cutting head connects slipway

No.2 socket head

wrench

Focus lens center

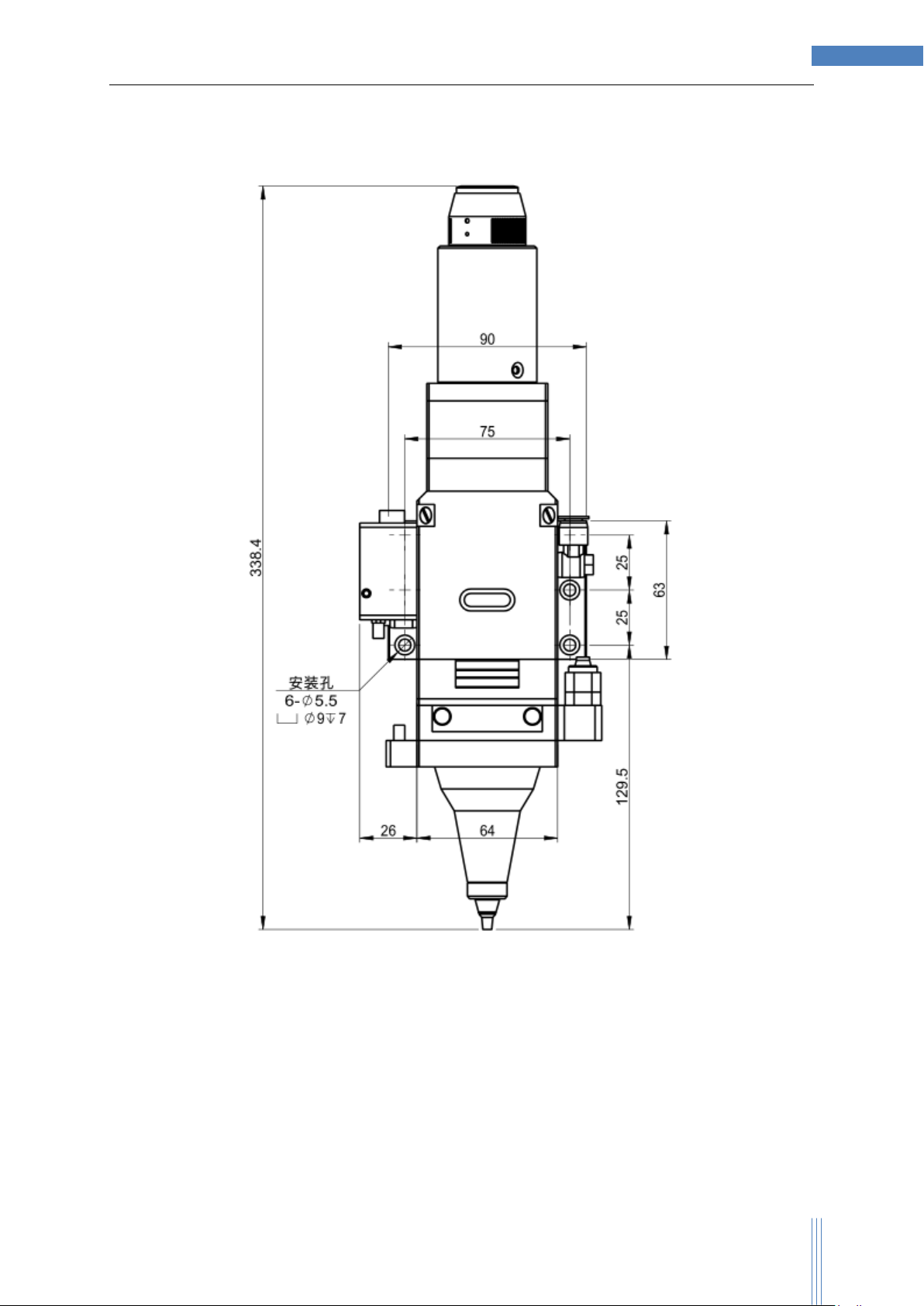

3.2 Installation Dimension of Cutting Head

Cutting head and machine tool are fixed by dead plates. On the backboard, there are six M5

fixing holes. Just as shown in the figure, when installing, tight up the corresponding position of

screw and Z-axis link block of machine tool; at the same time, installation position can be

adjusted according to customer requirements.

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

10

3.2.1 C4-QBH100-F125 and C4-QBH100-F150

(Contact us for more details)

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

11

3.2.2 C4-3D-QBH100-F125

(Contact us for more details)

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

12

3.2.3 C4-FC-QBH100-F50

(Contact us for more details)

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

13

3.3 Tube connection of C4 Process Head

C4 laser process head adopts the design of optical lens surrounded by water-cooling, which can

reduce the chance of lens damage by heat effectively and restrain the deformation of lens

caused by heat effect in the long operation.

In the following table, the detailed water-cooling environment that C4 process head needs is

provided:

Minimum flow rate

1.5L/min

Recommended flow rate

2.0 L/min

Recommended flow rate hydraulic

pressure

1.8 bar

Recommended temperature

15~35℃(above the temperature of moisture

condensation of environment)

Type of running water

Purified water

Connection type

Quick-inserting water pipe joint with diameter 6mm

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

14

3.4 QBH Connection

Operation sequence:

1. Take down the plastic protective cap at the top of link block.

2. Align the small hole on the QBH to the small hole on the link block, red dot to red dot,

insert QBH until the end.

3. Tighten up the set screw nut clockwise, just as shown in the figure.

4. Lift up the set screw nut and Tighten up it clockwise again.

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

15

4Focus Adjustments

4.1 Focus centering

The centering of all C4 fiber cutting head series are finished by the two adjusting screws just as

shown in the following figure. When centering, No. 2.5 socket head wrench is used. Clockwise

adjustment makes focus move to the direction of backboard and counterclockwise adjustment

makes focus move to the opposite direction. There are a total of two adjusting screws. The first

calibration is made before delivery, and when using, only a slight readjustment is needed.

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

16

4.2 Z position adjustments

The Z-axis position adjustment of all C5 fiber cutting head series are finished by the hand wheel

unit just as shown in the following figure. Clockwise adjustment of hand wheel makes focus

extend and counterclockwise adjustment of hand wheel makes focus shorten. When delivery, the

focus is placed the standard position from the nozzle 1mm and can be used for most cutting.

The moving ranges of focus lens are“0~8mm”. When it is adjusted to “0”, focus is at the nozzle

nearby (since focus lens has errors). When it is adjusted to “+4”, focus extends furthest away

from the nozzle and When it is adjusted to “-4”, focus has the most retraction into the nozzle.

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

17

5Operation &Maintenance

5.1 Maintenance of Protective windows

Protective window is at the bottom of focusing module. When lens sticks to impurities or foreign

matters, they cause damage to lens. Therefore, regular maintenance of window is needed. It is

suggested to clean it once a week. As for the structure of windows, please refer the figure below.

Protective windows are vulnerable parts and in case of damage, we need to replace it. During

maintenance/replacement, be sure to wear dust-proof gloves or finger stall so as to avoid the oil

stain and dust on hand from polluting lens.

5.1.1 Taking out of windows

Wear dust-proof gloves or finger stall; counterclockwise loosen the two set screws at the red

protective lens drawer; draw out protective lens slowly and steadily; move it to clean and tidy

indoor.

5.1.2 Disassembly of windows

1. Put the side with seal ring adown and hold lens base with left hand.

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

18

2. Gently squeeze the edge of the windows with right thumb from the top down (Note: be sure to

squeeze the edge, since squeezing the center cannot make the windows fall off), place the

index finger of right hand on the opposite direction of thumb so as to protect the lens from

slipping.

3. Keep on pressing down gently with thumb until seal ring and the lens fall off.

5.1.3 Clean Lens

A. Tools: dust-proof gloves/finger stall, continuous fiber absorbent cotton swab, isopropanol and

rubber air-blower.

B. Cleaning methods:

1. Wear finger stall on thumb and index finger of left hand.

2. Spray isopropanol onto fiber degreasing cotton swab.

3. Gently hold the edge of the side face of protective lens with thumb and index finger of left hand.

Notes: finger stall cannot touch the surface of lens to avoid leaving a mark.

4. Make the lenses directly face eyes, hold fiber absorbent cotton well with right hand, from left to

right or from down to up, gently clean the lens with the single direction (Never rub backwards and

forwards so as to avoid secondary pollution to lens), and blow the lens surface with rubber air-

blower. Both sides should be cleaned. After cleaning, it should be ensured that there is no any

following residue: detergents, absorbent cotton, foreign bodies and impurities.

Notes: after cleaning, the lens can't be exposed in the air, it should be installed as soon as

possible according to the method shown in 5.1.4 or temporarily kept in dry clean sealed container.

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

19

5.1.4 Front and back side are irrespective for the installation of

protective lens since both sides are plane.

1. Place protective lens base, lens, seal ring from bottom to top in turn, and compact them just as

shown in figure.

2. Refill into the bottom of lens module, and clockwise tighten the set screw by hand

5.2 Collimator and focus lens maintain

C4 fiber laser process head has excellent leak tightness, so regular inspection of its population is

unnecessary. But if the machine tool is frequently moved, the cleanness of the lens should be

inspected in the dust-free room before pulling in or pulling out fiber and re-installation

All collimators and focus lens come in holders, so it is much easier to get it replaced.

5.2.1 Take out of lens holder

First unload the 4 M3 socket head screws shown in above figure with socket head wrench,

wear dust-proof gloves/finger stall, loosen the XY adjusting screw and take out lens holder and

replace it.

5.2.2 Assemble the lens holder

Copyright © AU3TECH RESEARCH PTY LTD

C4 Cutting head Users Manual By Au3tech Research Pty Ltd

20

After finishing cleaning the lens by the steps of cleaning protective lens, wear dust-proof

gloves/finger stall, back-step by the steps of taking out lens and install the focusing lens well. Be

sure the plane of the lens adown during installation.

Table of contents

Other Au3Tech Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

GCC Technologies

GCC Technologies Laser Pro DFS Installation & operation manual

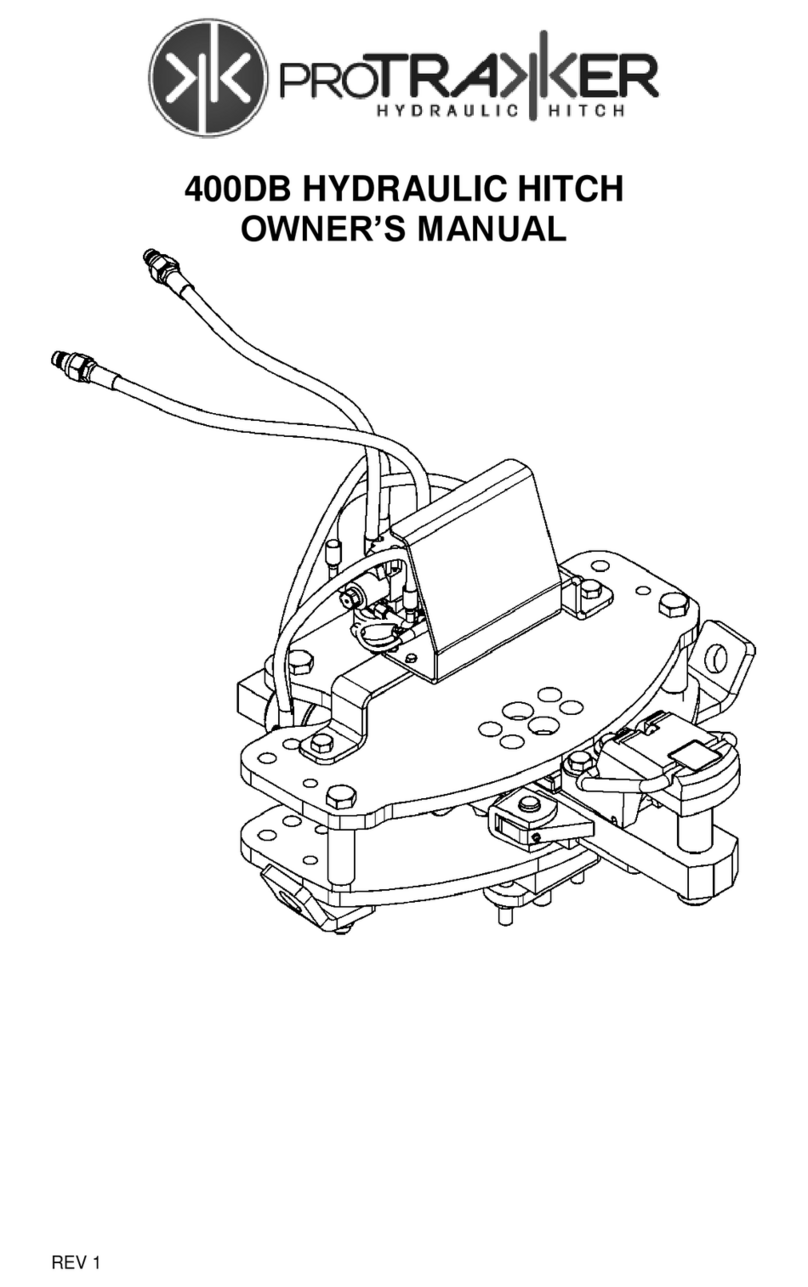

PROTRAKKER

PROTRAKKER 400DB owner's manual

TMG

TMG TMG-AB72 product manual

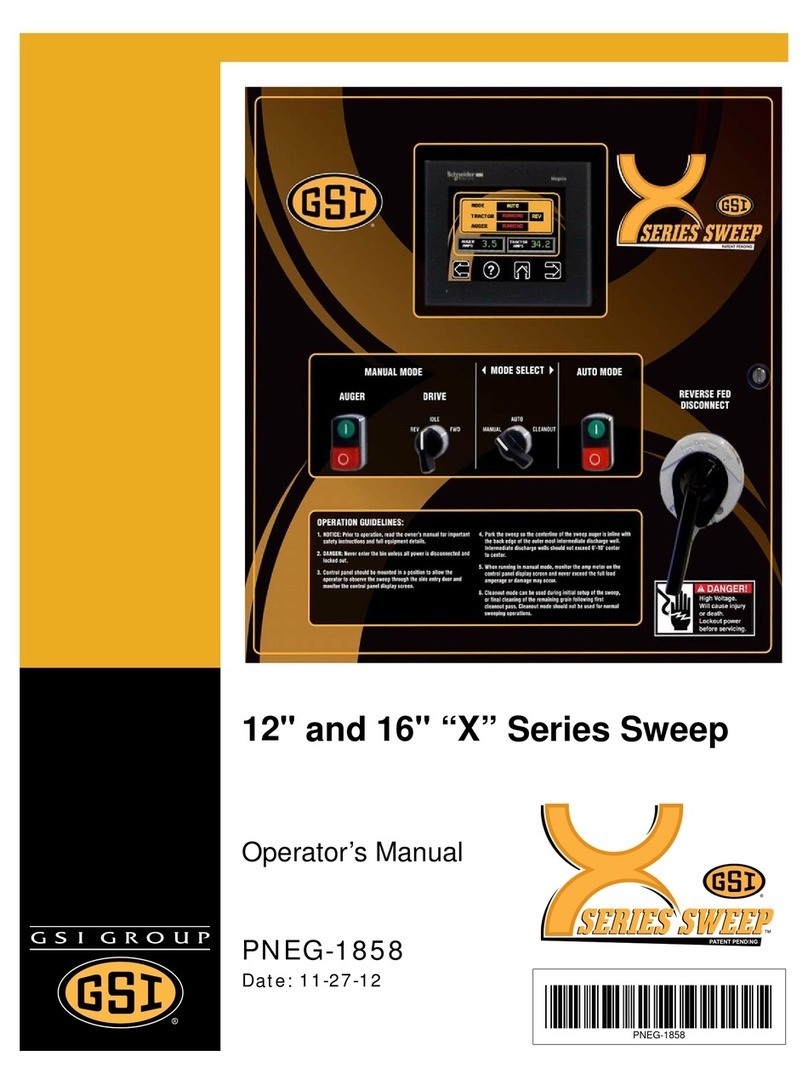

GSI Group

GSI Group X Series Sweep Operator's manual

Cascade TEK

Cascade TEK SVO-5-VC Installation and operational manual

Mannesmann Demag

Mannesmann Demag ESR AX25 Series installation instructions