COMMERCIAL PROTECTOR SYSTEM®

INSTALLATION INSTRUCTIONS

To reduce the risk of SERIOUS INJURY or DEATH:

• This device is for use ONLY on LiftMaster®Commercial Door

Operators.

• For INDOOR USE ONLY.

• Disconnect power BEFORE installing the Commercial Protector

System®.

• READ AND FOLLOW ALL INSTRUCTIONS.

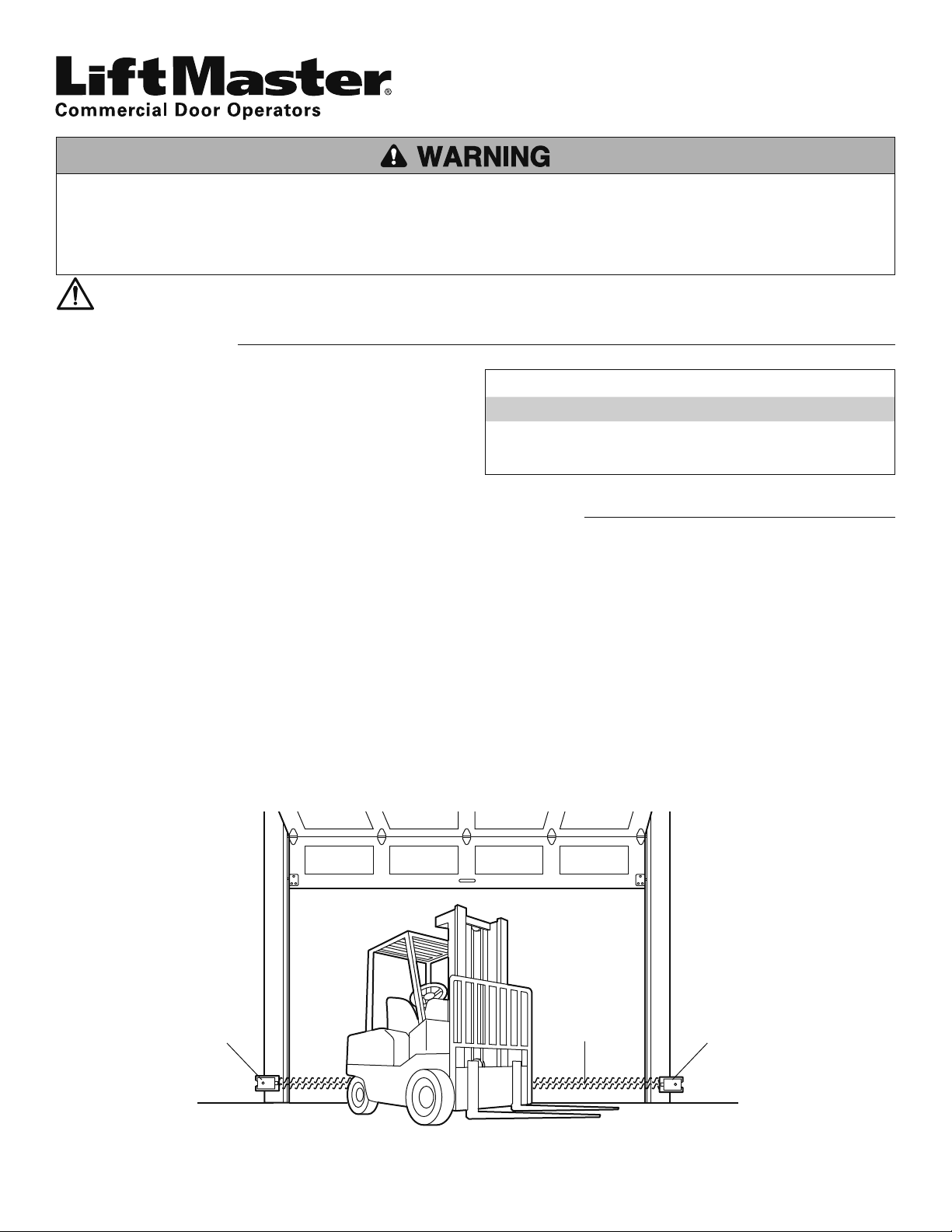

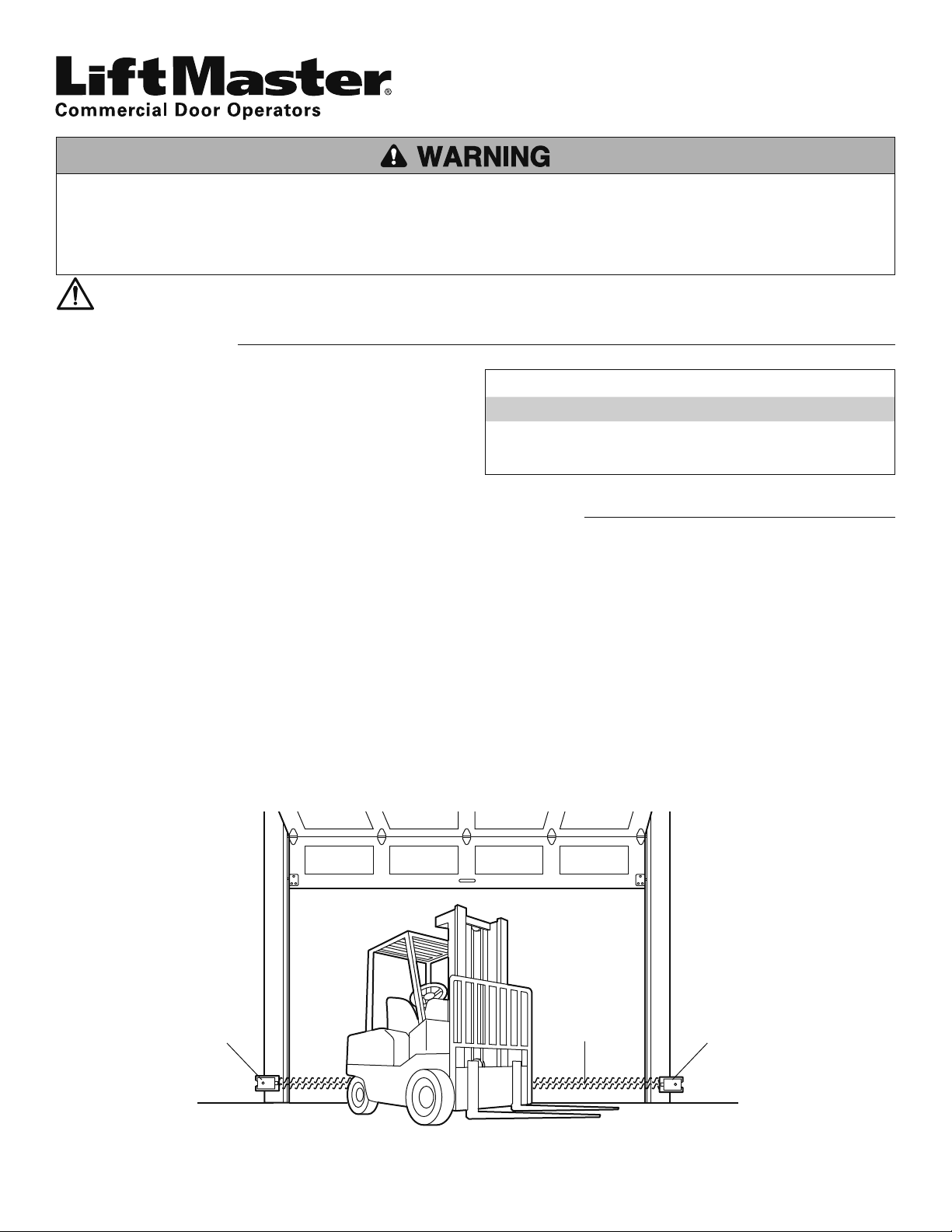

Facing the door from inside the garage (installation procedures are the same for all door types).

Left Side of Garage Right Side of Garage

Photoelectric Sensor

Photoelectric Sensor

Invisible Light Beam

Protection Area

THE COMMERCIAL PROTECTOR SYSTEM®

IMPORTANT INFORMATION ABOUT THE PHOTOELECTRIC SENSORS

Be sure power to the operator is disconnected.

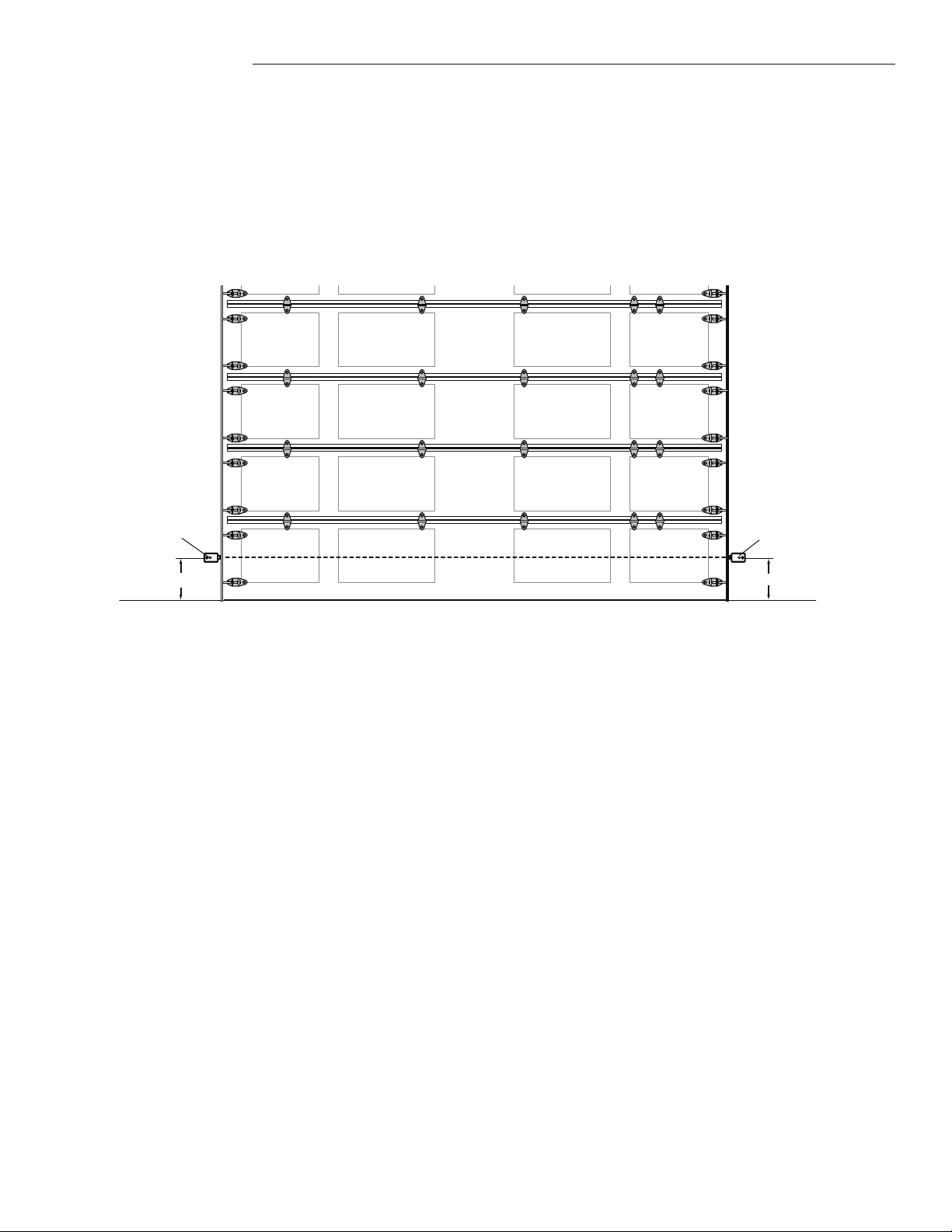

When properly connected and aligned, the photoelectric sensors will detect an obstruction in the path of its invisible light beam. If an

obstruction breaks the light beam while the door is closing, the door will stop and typically reverse to the full open position.

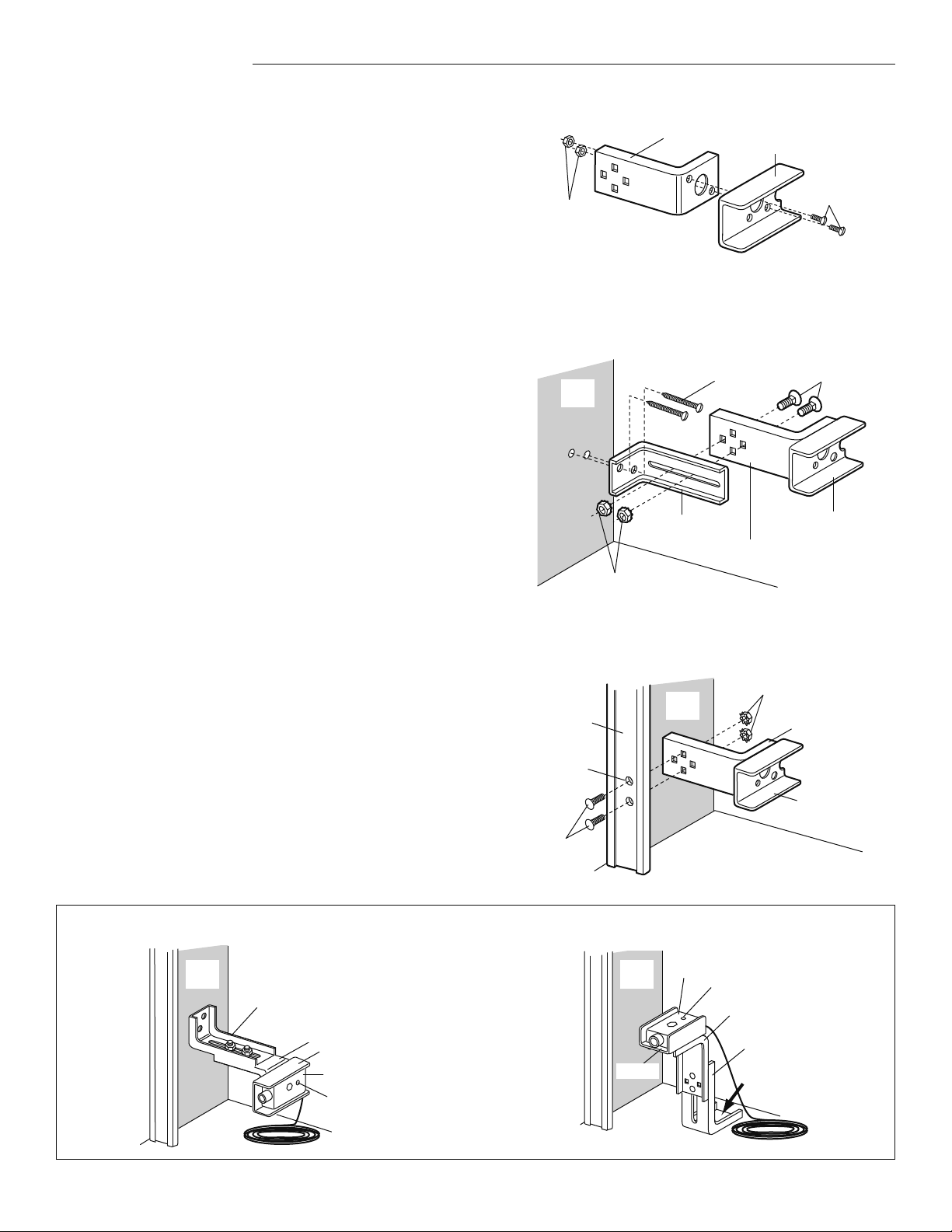

The photoelectric sensors must be installed inside the garage so that the sending and receiving sensors face each other across the door,

no more than 6" (15 cm) above the floor. Either can be installed on the left or right of the door as long as the sun never shines directly

into the receiving eye lens. This product is not suitable for outdoor use.

The brackets must be securely fastened to a solid surface such as the wall framing. If installing in masonry construction, add a piece of

wood at each location to avoid drilling extra holes in masonry if repositioning is necessary.

The invisible light beam path must be unobstructed. No part of the garage door (or door tracks, springs, hinges, rollers or other

hardware) may interrupt the beam while the door is closing. If it does, use a piece of wood to build out each sensor mounting location to

the minimum depth required for light beam clearance.

APPLICATION

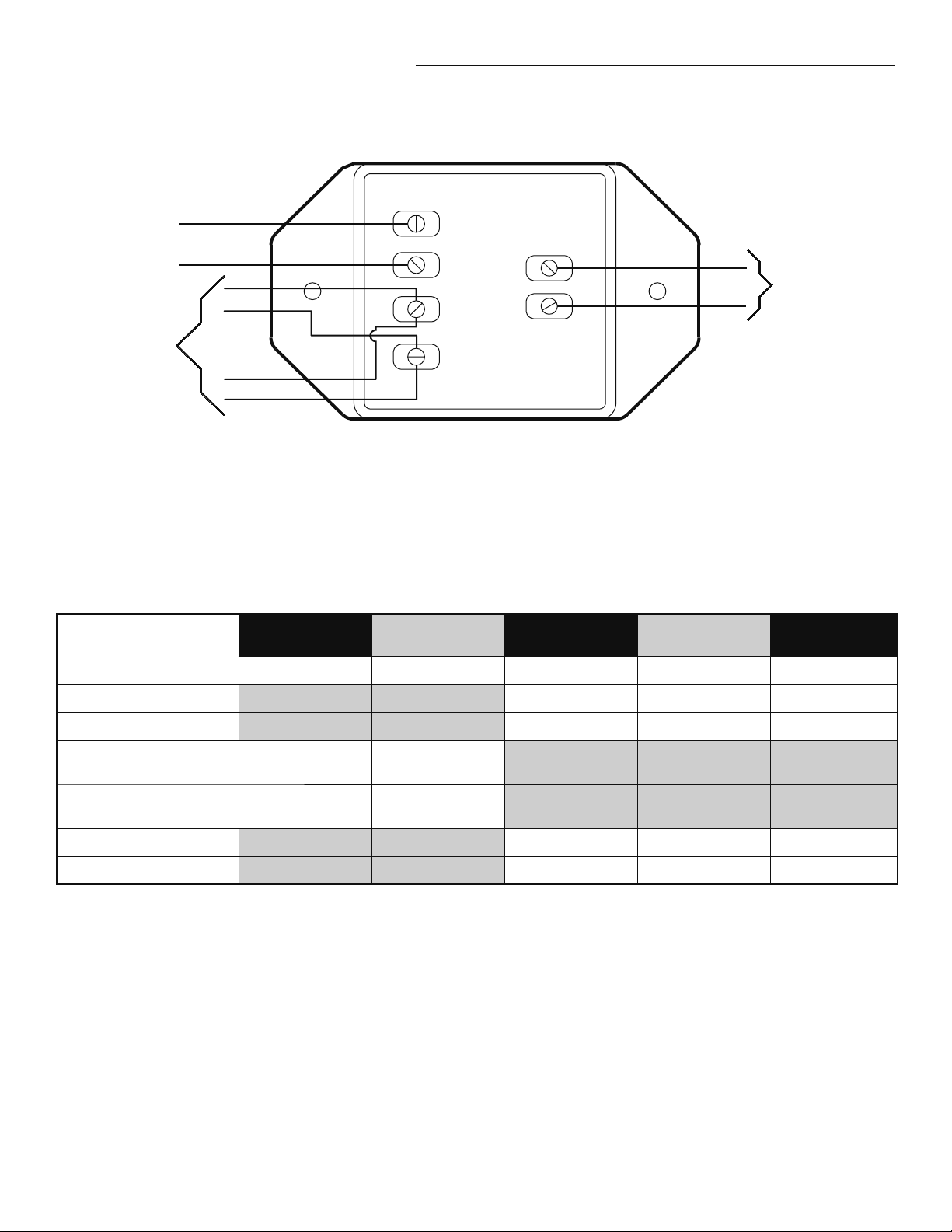

The Commercial Protector System®(CPS) is suitable for LiftMaster

Commercial Door Operators with a Normally Open (N.O.) sensing

edge input.

The CPS is for use with ancillary entrapment protection devices

only, and not used for primary monitored entrapment protection

devices.

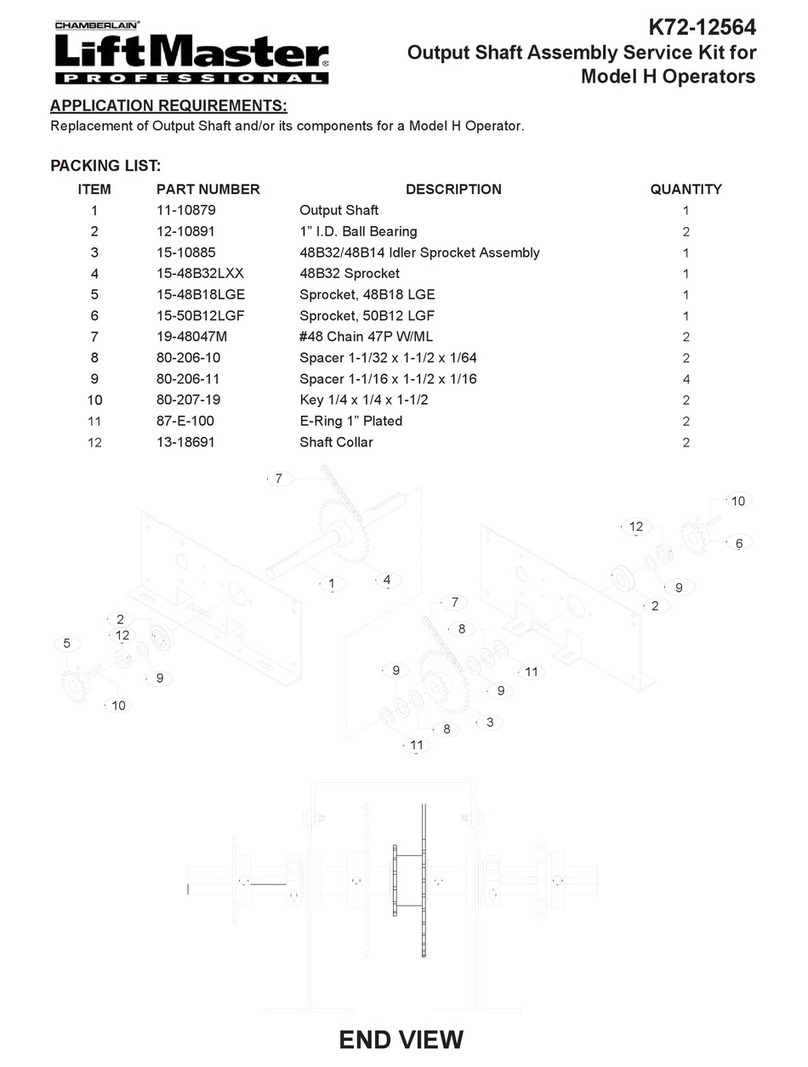

CARTON INVENTORY

PART # DESCRIPTION QTY

CPS-U Photoelectric Sensors with Mounting Hardware 1

41K4629 Commercial Protector Interface 1

WARNING: This product can expose you to chemicals including lead, which are known to the State of California to cause cancer or birth defects

or other reproductive harm. For more information go to www.P65Warnings.ca.gov