2| GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23

CONTENTS

1.0 INTRODUCTION .................................................................................................................3

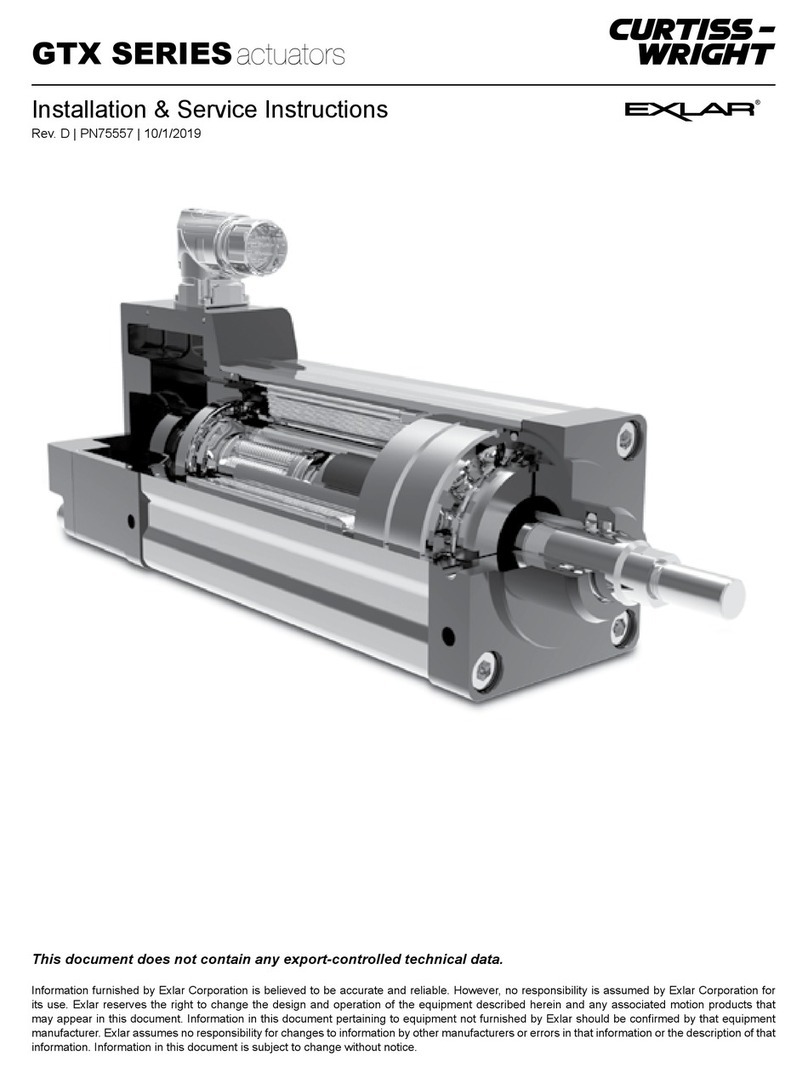

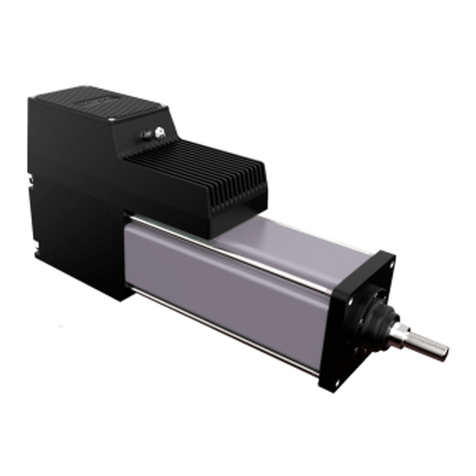

1.1 GENERAL PRODUCT DESCRIPTION .....................................................................................................3

1.2 PRODUCT FEATURES ..............................................................................................................................3

1.3 SAFETY CONSIDERATIONS ....................................................................................................................4

2.0 SYSTEM CONFIGURATION ..............................................................................................5

2.1 GTX SERIES ACTUATOR..........................................................................................................................5

2.2 OPTIONS.....................................................................................................................................................5

2.2.1 Servomotor Ampliers........................................................................................................................5

2.2.2 Feedback Devices .............................................................................................................................5

2.2.3 Resolvers...........................................................................................................................................5

2.2.4 Encoders............................................................................................................................................5

2.2.5 Internal Holding Brake .......................................................................................................................5

2.2.6 Anti-Rotation Assembly......................................................................................................................5

2.2.7 Splined Rod Options..........................................................................................................................6

2.2.8 External Limit Switch .........................................................................................................................6

2.2.9 Stainless Steel Rod Options ..............................................................................................................6

3.0 MECHANICAL INSTALLATION ..........................................................................................6

3.1 MOUNTING CONFIGURATIONS ..............................................................................................................6

3.2 MOUNTING CONSIDERATIONS ..............................................................................................................8

3.2.1 Actuator Alignment.............................................................................................................................8

3.2.2 Feedback Device Alignment ..............................................................................................................8

3.2.3 Anti-Rotation Assembly......................................................................................................................9

3.2.4 External Limit Switch .......................................................................................................................10

3.3 LUBRICATION .......................................................................................................................................... 11

4.0 ELECTRICAL INSTALLATION..........................................................................................11

4.1 SAFETY CONSIDERATIONS .................................................................................................................. 11

4.2 CABLE ROUTING..................................................................................................................................... 11

4.3 AMPLIFIER PINOUTS AND CONNECTIONS ........................................................................................12

4.4 CONNECTING OPTIONAL EQUIPMENT...............................................................................................12

4.4.1 Feedback Devices – Encoders ........................................................................................................12

4.4.2 Internal Holding Brake .....................................................................................................................12

4.4.3 External Limit Switch ......................................................................................................................12

5.0 STARTUP ...........................................................................................................................13

5.1 CONSIDERATIONS FOR STARTUP.......................................................................................................13

5.1.1 Safety Considerations......................................................................................................................13

5.1.2 Amplier Software............................................................................................................................13

5.1.3 Rotary-To-Linear Motion Relationship .............................................................................................13

5.1.4 Amplier Wiring................................................................................................................................13

5.2 GENERAL STARTUP PROCEDURE ......................................................................................................13

6.0 MAINTENANCE PROCEDURES .....................................................................................15

6.1 LUBRICATION ..........................................................................................................................................15

Grease Renewal Procedure ....................................................................................................................15

6.2 SEAL MAINTENANCE..............................................................................................................................15

6.3 REPLACEMENT FACEPLATE ASSEMBLY KIT.....................................................................................16

7.0 TROUBLESHOOTING ......................................................................................................16

8.0 PRODUCT RETURNS.......................................................................................................17

9.0 CERTIFICATIONS .............................................................................................................17

9.1 IMPORTER REQUIREMENTS ................................................................................................................18

9.2 DISTRIBUTOR REQUIREMENTS ..........................................................................................................19

10.0 WARRANTY INFORMATION..........................................................................................20