13

LKS - S2 24V DC

Tools required

• Marker,

• Grains,

• Hammer,

• Screwdriver (slotted-head, cross or Torx)

size by site conditions,

• Hexagonal wrench size 3 / 4 / 5 / 6,

• Torque wrench,

• Power drill,

• Threadlock adhesive,

• possibly a tool for blind rivet nuts (size 6).

InstallatIon step 2: inStallation PReReQuiSite anD inStallation PRePaRation

The following conditions must be fullled for the instal-

lation of the drives so they can be properly assembled with

other parts and constructed to a complete machine at the

window without impairing the safety and health of persons:

1. The design of the drive must fulll the requirements.

2. The fastening accessories (casement brackets or

frame brackets) must t the window prole; the

prole-dependent hole lay-out must be complied with.

3. The space required for the installation of the drive on

the frame and casement prole must be sufcient.

4. The window must be in perfect mechanical condition

before the installation. It should open and close easily.

5. The fastening material for the installation of the drive

must t the window material (see table).

Check window data on site

• Measure FAB and FAH.

• Check / calculate weight of casement.

If unknown, it can be determined approximately with

the following formula:

• Check / calculate the required drive force and compare

with drive data . If unknown, it can be determined

approximately with the following formula:

a= Distance of action point to hinges

F= Drive force

s= Stroke

weight) [kg] [m] [m] [mm] frame

share

glass-

density

G (Casement = FAB *FAH *Glass thickness * 2,5 *1,1

F[N] =

Facade Roof

F[N] =

5,4 *G[kg] *s[m] 5,4 *G[kg] *FAH [m]

a[m] a[m]

Wood windows

Wood screws:

i.e. DIN 96, DIN 7996, DIN 571

round head with slot,

round head with cross,

hex head,special type

steel, stainless steel,

aluminum windows

Self-tapping screws, thread screws,

sheet-metal screws

i.e. ISO 4762, ISO 4017, ISO 7049 , ISO 7085, DIN 7500

cylinder head with hex socket, internal serration (Torx),

Phillips head or external hex head

blind rivet nut

plastic windows

Screws for plastic

i.e. DIN 95606, DIN 95607, ISO 7049,

ISO 7085, DIN 7500

round head with cross, external hex head,

Torx

Recommendation:

if possible, screw

through two cavity

webs

Scope of delivery:

Prior to assembly, check items quantity in the delivery for

completeness.

a

G

s

FAH

F

a

F

FAH

a

s

G

F

FAH

PreParing assembly

04

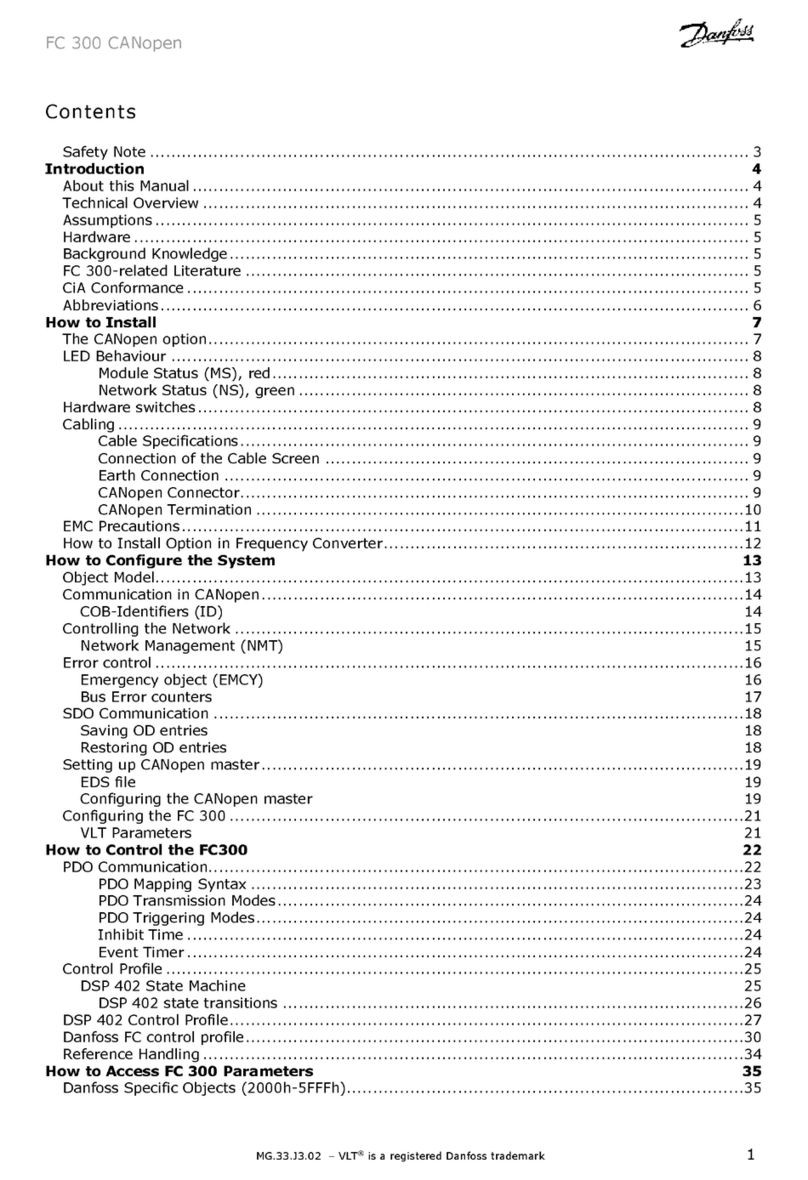

Positioning of the drives at the HSK

One drive Two drive - stroke max. 300 mm

HSK

1/2 FAB

1/2 FAB

1/2 FAB 1/4 FAB1/4 FAB

Tools required

• Marker,

• Grains,

• Hammer,

• Screwdriver (slotted-head, cross or Torx)

size by site conditions,

• Hexagonal wrench size 4 / 5

• Fork wrench for SW 13, SW 14

• Torque wrench,

• Power drill,

• Threadlock adhesive,

• possibly a tool for blind rivet nuts (size 6).

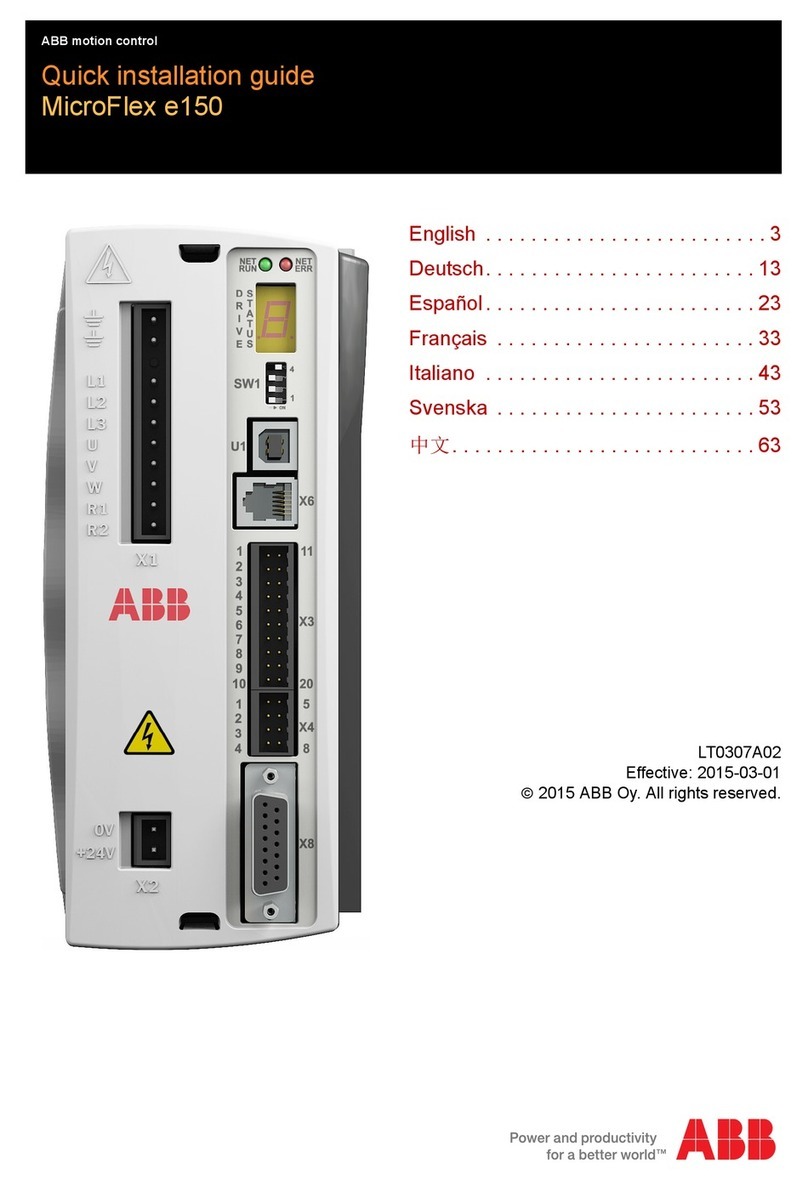

Accessories: LKS

Assembly Instructions

Warning sign sticker

„Risk of entrapment“

LKS- S2 24V DC

2

LKS- S2 24V DC

1LKS- S2 24V DC

4LKS- S2 24V DC

6

LKS- S2 24V DC

3LKS- S2 24V DC

5

~60

30

43,5

~73

LKS Part.-No. L (mm)

LKS 100S2 24V DC 513100 263

LKS 200S2 24V DC 513200 363

LKS 300S2 24V DC 513300 463

LKS 400S2 24V DC 513400 563

LKS 500S2 24V DC 513500 663

LKS 600S2 24V DC 513600 763

LKS 750S2 24V DC 513800 913

LKS1000 S2 24V DC 513805 1163

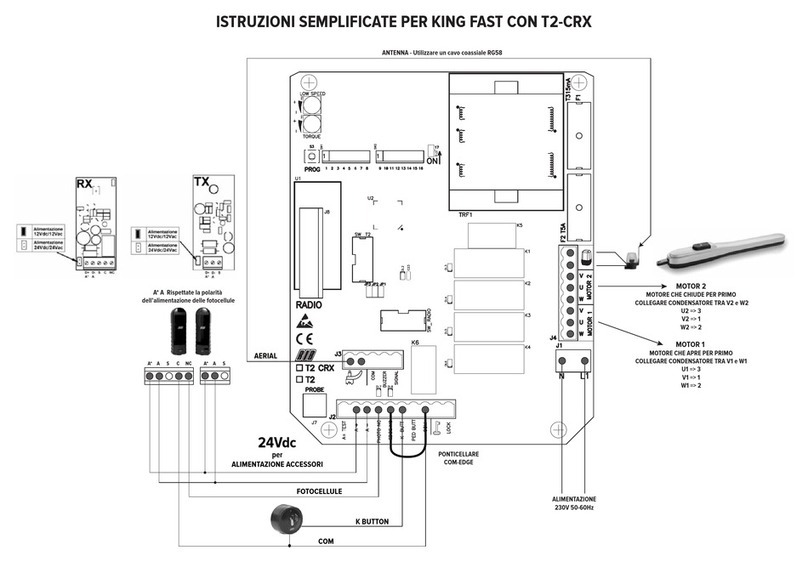

F1 F10.6

K82 K5

B7 K21K

K29

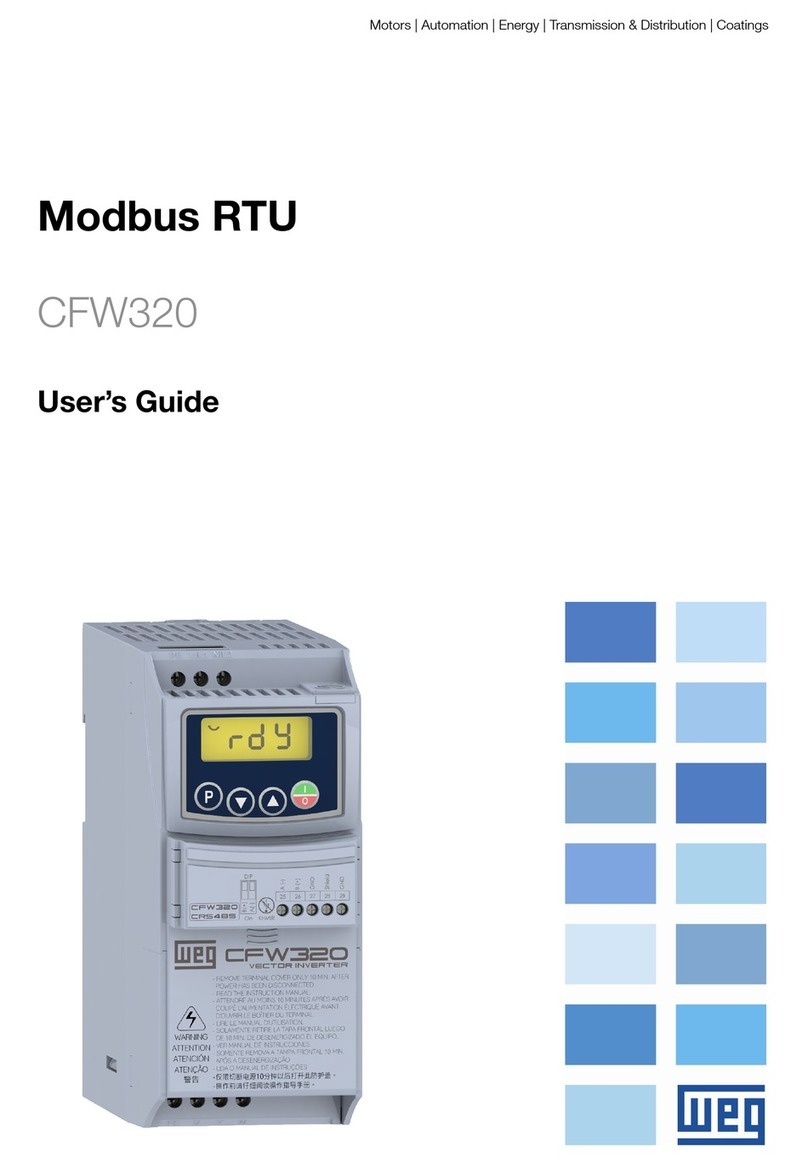

HSK HSK

1

2

LKS

BN +

-

BU

-

+

+

+

-

-

Polarityreversal

OPEN

CLOSE

3

5

4

Video-Linkto the detailed assembly instructions

20

46

18

Ø6

60

Ø6,5

x2

40

70

1

5

12,5

40

50

Ø6,5

x4

50

30

40

Ø6,5

x6

68

30

12,5

17,5

43,5 20

60

56

Ø12

max.10 Nm

70

50

40

1713

30

Ø6,5

x7

40

40

66

15

40

37

7

LKS

BN

K29

K82

s

45,5

16,5

30

40

83,5

156 28±7

Ø6

Ø6

83,5

113,5

F1 F10.6

LKS

LKS

1515

40

parallel

parallel

1/2

1/2

F1

K29

LKS

LKSLKS

1/2

1/2

parallel

K82

F10.6

M6

M6

LKS

B7

LKS

K82

B7

F10.6

F10.6

LKS

LKS

8

35

30

20

6

Ø6,5

6

Ø6

Notethe safety instructions!

Linksto safety instructions, assembly instructions,

andmanufacturer statements: Please scan in the QR

codeand follow the link to the AuMüLLer homepage.

Sicherheitshinweisebeachten!

Linkszu Sicherheitshinweise, Montage-Anweisungen

undHersteller-Erklärungen: Bitte QR-Code einlesen

undLink zur AuMüLLer-Homepage verfolgen.

Respectezles consignes de sécurité!

Liensvers les consignes de sécurité, instructions de

montageet les explications du fabricant: Veuillez

scannerle code QR et suivre le lien vers la page d’ac-

cueilde AuMüLLer.

请遵守安全说明!

关于装配说明的链接 和制造商声明

请读取 QR码并跟踪 AuMüLLer 主页的链接。

Соблюдайте правила техники

безопасности!

Сылки на инструкции по монтажу и

декларации производителя: Пожалуйста,

считайте QR-код и перейдите по ссылке на

главную страницу AuMüLLer.

Przestrzegaćwskazówek bezpieczeństwa!

Linkdo instrukcji montażu i uruchomienia:

Proszęzeskanować kod QR i otworzyć stronę

AuMüLLer.

Veiligheidsinstructiesin acht nemen!

Linksnaar veiligheidsinstructies, montage-instructies

enfabrikantenverklaringen: Gelieve QR-code in te

lezenen link naar de AuMüLLer-homepage te volgen.

eN

De

ru

Fr

PL

NL

CN

Assembly InstructIon

lKs (Rack and pinion drives)

accordingto Machinery Directive

2006/42/EG (annex VI)

Rackand PiniondRive foR windows

9000028511_V0.1_KW50/19

www.aumueller-gmbh.de

AUMÜLLERAUMATICGMBH

Gemeindewald11

86672Thierhaupten

Tel.+49 8271 8185-0

Fax+49 8271 8185-250

1/2

1/2

parallel

F1

K29

M6

16

parallel

15

40

B7

M8(no.4)

M8(SW13)

K82

F10.6

max.15 Nm

G1/8“/SW14

B7

max.10 Nm

M6(no.5)