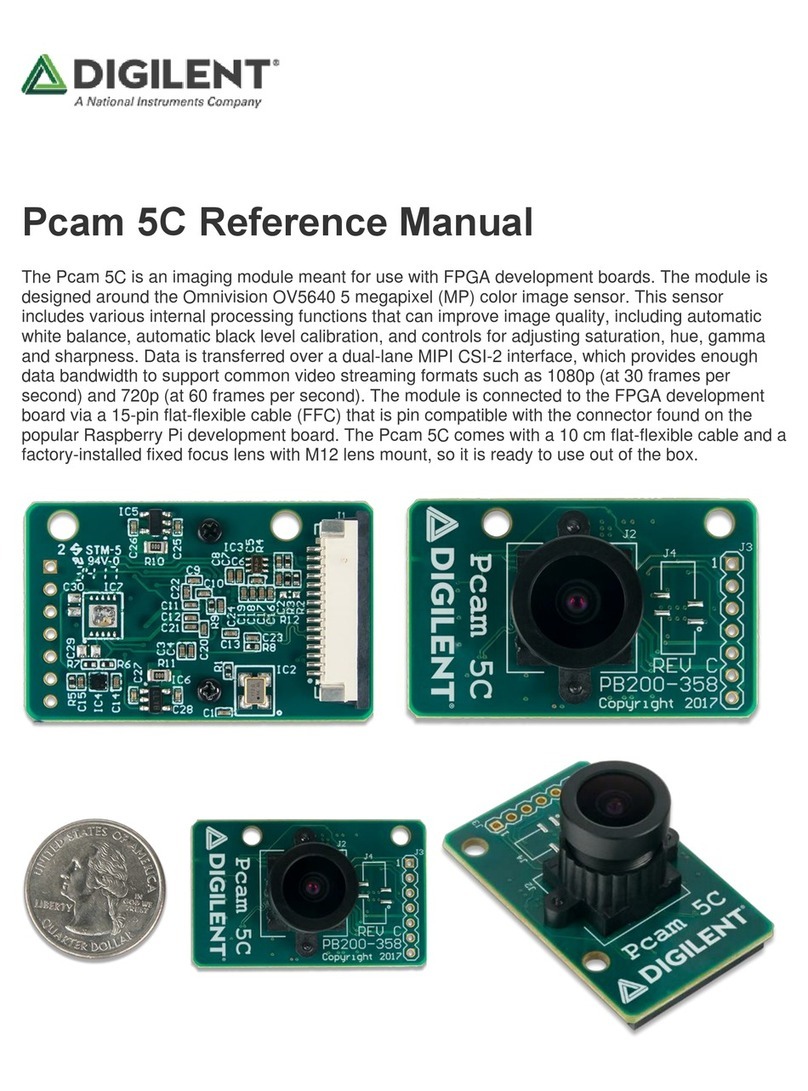

auto maskin Marine Pro DCU 210E User manual

Manual# 1006495

Installation Manual

200E Series

DCU 210E/208E –Engine Panel

RP 210E/220E –Remote Panel

Installation Manual

for the

Marine Pro 200E Series

~~~

DCU 210E/208E Diesel Engine Control Unit

RP 210E/220E Remote Panel

Revision

1.6

Revised

September 27, 2017

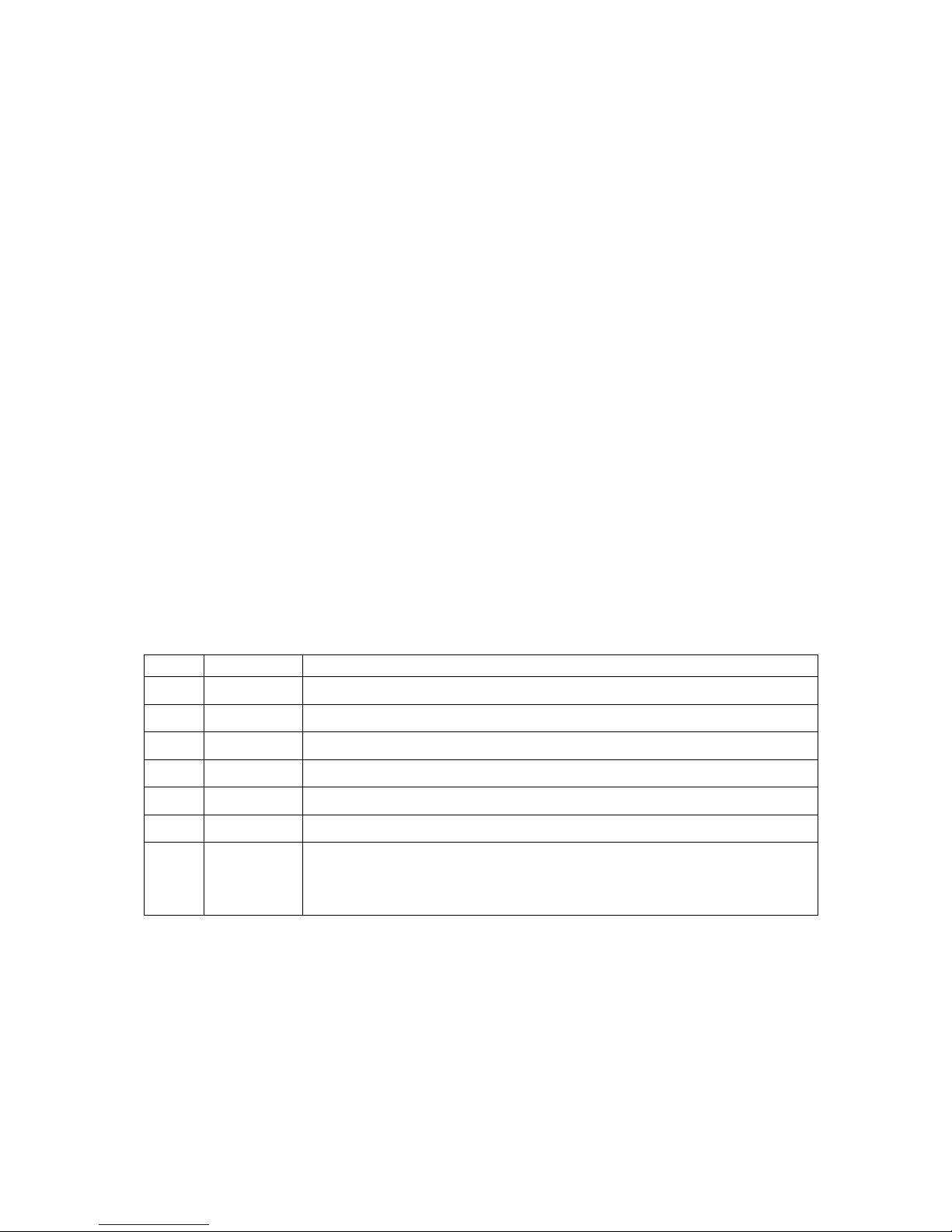

Revision history:

Rev.

Date

Description

1.0

2.9.2015

Initial release.

1.1

4.9.2015

Corrected thermistor terminals on page 6.

1.2

9.2.2016

Updated the connector pinout description page 6.

1.3

15.2.2016

Added connections drawing page 12.

1.4

18.3.2016

Thermistor 2, 3 and 4-wire drawings.

1.5

25.11.2016

RP 220E added.

1.6

25.09.2017

Added installation notes released to Ethernet and switches. Added

voltage sensor inputs. Updated to SW 3.6. Communication I/O link

updated.

Copyright © 2017 by Auto-Maskin AS.

All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Auto-Maskin AS.

Installation Manual –200E Series Page iii

Table of Content

DOCUMENT INFORMATION ................................ 1

ABOUT THIS MANUAL .............................................. 1

Responsibilities .............................................. 1

MATCHING FIRMWARE ............................................ 1

ORDERING INFORMATION......................................... 1

OVERVIEW OF THE 200 SERIES .................................. 2

DCU 210E Engine Panel ................................. 2

DCU 208E Engine Panel ................................. 2

Configuration................................................. 2

RP 210E/220E Remote Panel......................... 2

Ethernet Switch ............................................. 3

Expansion ...................................................... 3

INSTALLATION..................................................... 4

PANEL LOCATION .................................................... 4

DCU 210E....................................................... 4

DCU 208E....................................................... 4

RP 210E/220E ................................................ 4

Compatible panel series ................................ 4

General .......................................................... 4

Panel Cut-out................................................. 5

Mounting bracket.......................................... 5

CONNECTORS......................................................... 5

Connector kit ................................................. 5

Connector pinout –DCU 210E and 208E ...... 6

Connector pinout –RP 210E/220E................ 7

WIRING CONNECTIONS ............................................ 8

General .......................................................... 8

Grounding...................................................... 8

Power Supply [C1P11 –C1P12]...................... 8

RIO Link [C1P5 –C1P6] .................................. 9

J1939 CANbus [C1P7 –C1P9 and C2P10 –

C2P11] ........................................................... 9

All Faults Relay [C2P1 –C2P3] ....................... 9

Relay #1 [C2P4 –C2P6].................................. 9

Relay #2 [C2P7 –C2P9].................................. 9

Magnetic Pickup, MPU [C4P1 –C4P2]........... 9

Modbus RS-485 [C4P3 –C4P5] ...................... 9

Thermistor Input [C4P6 –C4P11] ................ 10

Flexible I/O [I/O #1 –I/O #19] ..................... 10

Other Interfaces........................................... 11

FIRST POWER-ON................................................. 11

Preparations ................................................ 11

First Power-On Wizard ................................ 11

APPENDIX A....................................................... 12

Typical sensor connections DCU 210E ......... 12

Installation Manual –200E Series Page 1

Document

Information

About this manual

This manual has been published

primarily for professionals and

qualified personnel.

The user of this material is assumed to

have basic knowledge in marine

systems, and must be able to carry out

related electrical work.

Work on the low-voltage circuit should

only be carried out by qualified and

experienced personnel.

Installation or work on the shore

power equipment

must only

be carried

out by electricians authorized to work

with such installations.

Responsibilities

It is the

sole responsibility of the

installer

to ensure that the installation

work is carried out in a satisfactorily

manner, that it is operationally in good

order, that the approved material and

accessories are used and that the

installation meet all applicable rules

and regulations.

Note! Auto-Maskin continuously

upgrades its products and reserves the

right to make changes and

improvements without prior notice.

All information in this manual is based

upon information at the time of

printing.

For updated information, please

contact your local distributor.

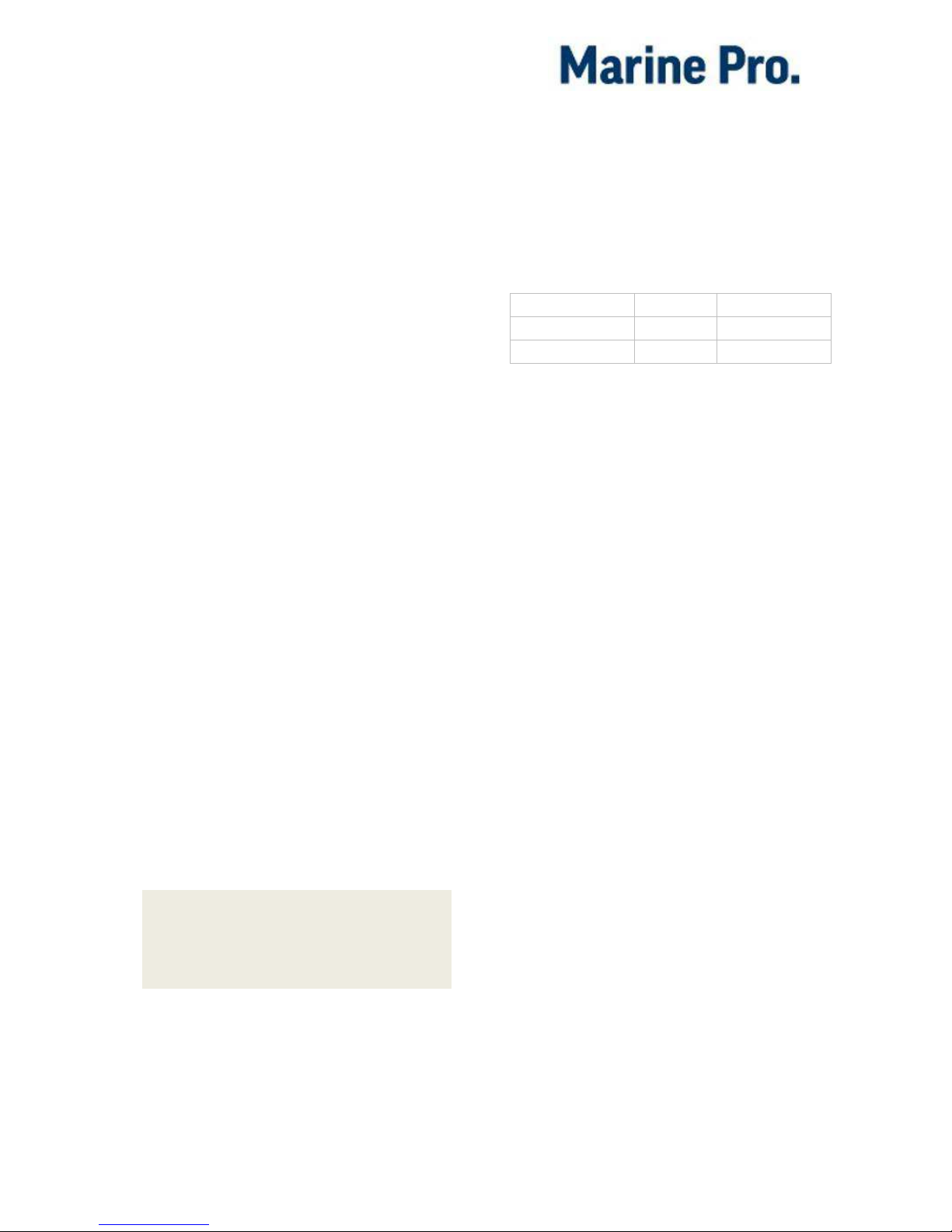

Matching firmware

This Installation Manual is for the 200E

Series of panels.

It has been updated to match the

following firmware releases.

Panel

Firmware

Release

DCU 210E/ 208E

3.6

August 2017

RP 210E/220E

3.6

August 2017

Ordering information

The Marine Pro covers a wide range of

compatible products within both the

200- and 400 Series. Please visit our

web site for more information.

http://auto-maskin.com/marine/

Installation Manual –200E Series Page 2

Overview of the 200

series

The drawing below shows a typical

layout.

DCU 210E Engine Panel

The DCU 210E engine panel is the

main building block in the 200 Series.

Engine sensor values are displayed on

the color touch screen, and commands

and other user interaction is also here.

DCU 208E Engine Panel

The DCU 208E is basically the same as

the DCU 210E, but without the color

touch screen.

It saves cost being used in smaller

engine rooms, where a remote panel is

all that is needed.

Configuration

An ordinary PC web-browser is used

to configure the DCU, using the inbuilt

web-server on the DCU.

RP 210E/220E Remote Panel

The optional RP remote panel brings

everything on the DCU to a remote

location, with the exact same user

interface. It does not need any

configuration, as it is reading the

configuration from the DCU.

Installation Manual –200E Series Page 3

As such, the RP can easily be

retrofitted.

The RP also supports one IP-camera to

be installed on the network.

Ethernet Switch

The Ethernet switch is not necessary if

only one DCU 210E and one RP

210E/220E is in use. These can then

be wired with an Ethernet cable

directly.

It is recommended to make use of an

Ethernet switch though, as it simplifies

PC configuration connection and

future expansion to remote panels

and/or camera interface.

Note! For redundant Ethernet

connection,

managed

Ethernet

switches must be used.

Expansion

The basic system can be expanded

with more input and output channels

using the versatile RIO units (Remote

I/O).

Currently, there are RIO units for

I/O expansion, RIO 410 and RIO

210.

Exhaust temperature

monitoring, RIO 412

Generator monitoring, RIO 425

Load sharing, LSU 408

Installation Manual –200E Series Page 4

Installation

Installation covers panel location,

wiring and first power-on.

Panel location

This section gives basic guidelines for

installing the different panels.

DCU 210E

The panel is normally located in the

engine room for a number of reasons.

The main reasons are:

Local operation and overview.

Minimize cabling requirements

and cost from sensors to panel.

Reduce of electrical noise levels

resulting from long cables.

DCU 208E

This panel is also normally installed in

the engine room, close to the engine.

Unlike the DCU 210E and the RP

210E/220E the DCU 208E is installed

on a din-rail.

The panel does not have a user

interface and is normally used in

unmanned engine rooms.

A RP 210E/220E remote panel is used

to bring the signals from the engine

room to a monitoring site, e.g. bridge

or wheelhouse.

RP 210E/220E

The RP remote panel is normally

located at a remote place away from

the engine room, but it can also be

used in the engine room.

Compatible panel series

Note that the 200 series panel can be

used together with the 400 series

panels.

For instance can a RP 210E/220E

remote panel be used to monitor a

DCU 410 engine panel.

General

Panels with a screen should be

mounted at about eye level and the

user should have easy access to

operate the panel.

Ensure easy access to the rear wiring.

The panel may be mounted on the

engines supporting structure provided

shock absorbers are used either

between the structure and the engine,

or between the structure and the panel

enclosure.

Installation Manual –200E Series Page 5

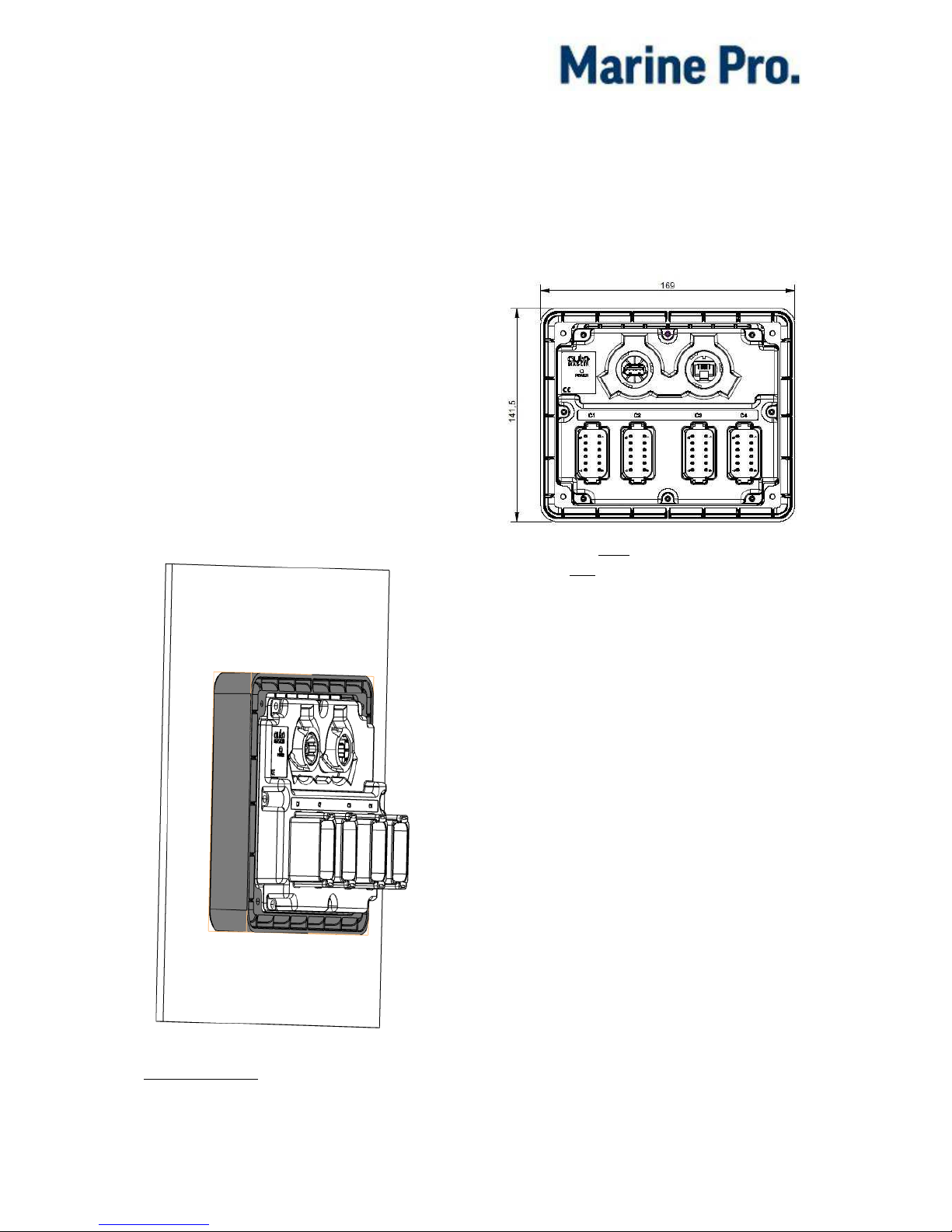

Panel Cut-out

The DCU and RP cut-out size is:

153mm width, 123 mm height

Mounting bracket

DCU 210E and RP 210E/220E

When installing the panel make sure to

use the bundled screws and mounting

bracket.

If installing the panel on a thicker

surface than 5mm, longer flanged

screws must be used. In this case M3

16mm flanged screws is

recommended.

Make sure that the screws are not too

long, as this will damage the panel.

The DCU 210E / RP 210E installed with the

mounting bracket shown in grey.

Connectors

DCU 210E, DCU 208E, RP 210E

and RP 220E

These are the connectors on the DCU

and RP back lid.

The DCU 208E front view is the same as the

DCU 210E rear view.

Connector kit

The 200E series is not shipped with

mating connectors.

A complete kit is available containing

all of the mating terminal blocks used

on the 200 E series.

Kit 1006479 contains:

4 Deutsch DT series connectors

(DT06-12SA).

50 hand crimp sockets 0.5 -1.0

mm2(16-20 AWG).

10 hand crimp sockets 1.0 -2.0

mm2(14-16 AWG).

50 sealing plugs for unused

terminals.

A crimp tool is necessary for

proper crimping of the mating

terminals. Use Deutsch HDT-48-00

crimping tool.

Installation Manual –200E Series Page 6

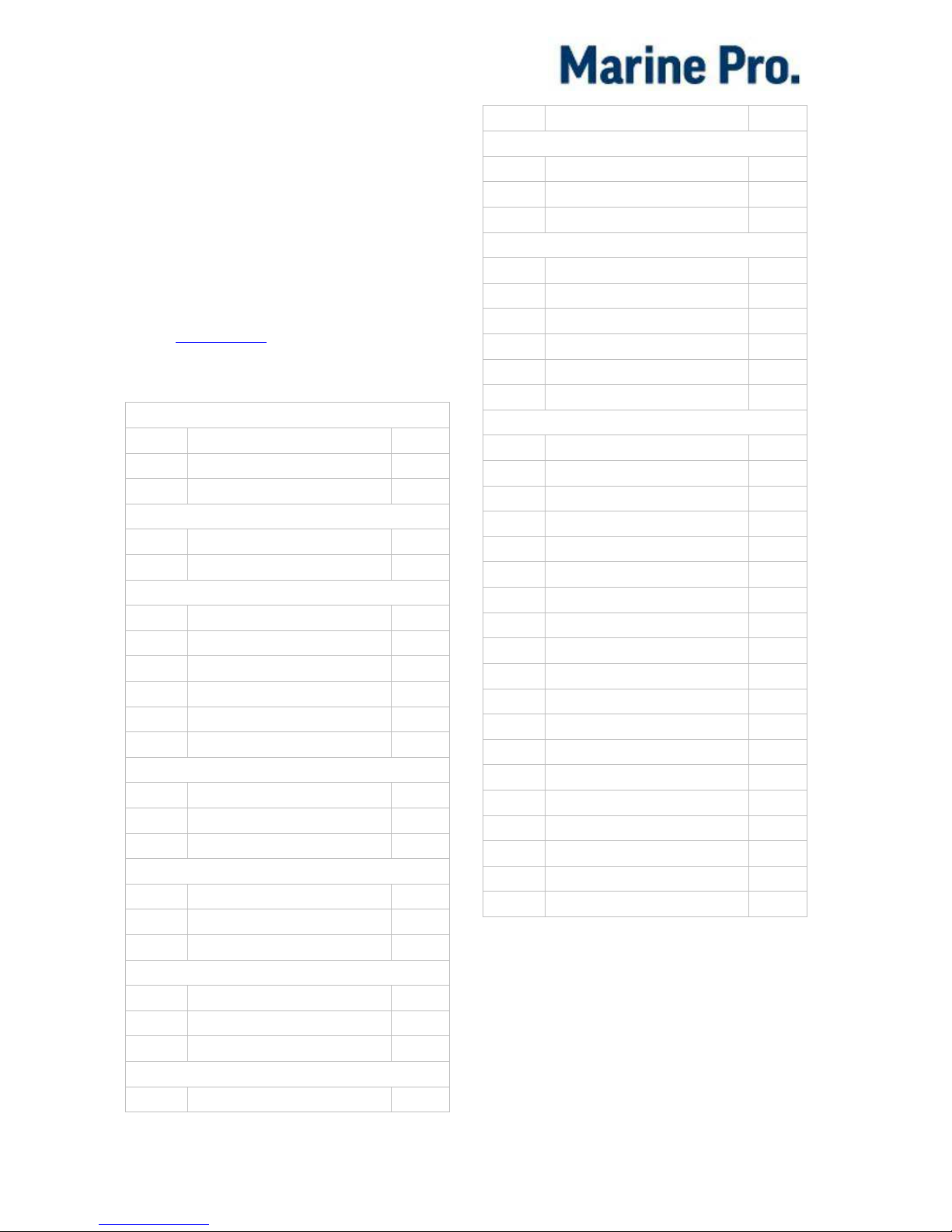

Connector pinout –

DCU 210E and 208E

The table below shows the connector

pinout on the DCU panels.

The connector is described as e.g.

C1P2. Where 1 is the connector

number and 2 is the pin number.

See Appendix A to see typical sensor

connections DCU 210E.

Power Supply

C1P11

+12/24VDC Primary Supply

In/Out

C1P12

0V Primary Supply

In

C1P3

Ground connection

In

RIO Link Interface

C1P5

Low

In

C1P6

High

In

CAN J1939 Engine Interface

C1P7

CAN 1High

In

C1P8

CAN 1 Low

In

C1P9

CAN 1 Shield

In

C2P10

CAN 2 High - (I/O #203)

In

C2P11

CAN 2 Low - (I/O #213)

In

C2P12

CAN 2 Shield - (I/O #5)

In

All Faults Relay (Inactive on fault)

C2P1

NC

-

C2P2

Common

-

C2P3

NO

-

On Board Relay #1

C2P4

NC

-

C2P5

Common

-

C2P6

NO

-

On Board Relay #2

C2P7

NC

-

C2P8

Common

-

C2P9

NO

-

Magnetic Pickup

C4P1

A

In

C4P2

B - (I/O #181)

In

Modbus RTU, RS-485

C4P3

Shield

In

C4P4

Low

In

C4P5

High

In

Thermistor Input

C4P6

Thermistor #1 A

In

C4P7

Thermistor #1 B

In

C4P8

Thermistor #1 C

In

C4P9

Thermistor #2 A

In

C4P10

Thermistor #2 B

In

C4P11

Thermistor #2 C

In

Flexible I/O

C1P1

I/O #1

In/Out

C1P2

I/O #21

In/Out

C1P4

I/O #3

In/Out

C1P10

I/O #4

In/Out

C2P12

I/O #51

In/Out

C3P1

I/O #62/ Sensor Power

In/Out

C3P2

I/O #7

In/Out

C3P3

I/O #8

In/Out

C3P4

I/O #9

In/Out

C3P5

I/O #10

In/Out

C3P6

I/O #11

In/Out

C3P7

I/O #121

In/Out

C3P8

I/O #13

In/Out

C3P9

I/O #14

In/Out

C3P10

I/O #15

In/Out

C3P11

I/O #16

In/Out

C3P12

I/O #17

In/Out

C4P2

I/O #181

In/Out

C4P12

I/O #19

In/Out

1Configurable as flexible I/O or as a 0V

reference.

2Configurable as flexible I/O or supply for 0-

5V sensors.

3Alternative I/O function is digital input only.

Installation Manual –200E Series Page 7

Connector pinout –

RP 210E/220E

The table below shows the connector

pinout on the RP panel.

The connector is described as e.g.

C1P2. Where 1 is the connector

number and 2 is the pin number.

Power Supply

C1P11

+12/24VDC Primary Supply

In/Out

C1P12

0V Primary Supply

In

C1P3

Ground connection

In

Switch Input

C1P1

Switch Input #1

In

C1P2

Switch Input #2

In

C1P4

Switch Input #3

In

All Faults Relay (Inactive on fault)

C2P1

NC

-

C2P2

Common

-

C2P3

NO

-

Installation Manual –200E Series Page 8

Wiring Connections

The following chapter primarily

assumes a DCU panel.

If installing an RP, then just disregard

descriptions that is not described in

the table “Connector Pinout RP

210E/220E”.

General

To protect against EMC noise, we

recommend that all cables are

shielded.

Note! The shield of all cables shall be

connected to ground/hull,

not

to 0V!

For good electrical noise separation,

consider routing some cables separate

from other cables –for instance the

pickup signal cable.

Note! Connect shield in one end of the

cable only.

Grounding

In marine installations, ground and 0V

volt should not be connected together.

In a ship installation, the hull is the

“ground” whilst the battery minus is

the 0V.

In the DCU system, +12/24V and 0V

are filtered to ground using special

filter components. This is done to

reduce electrical noise entering the

system.

Note! Please keep ground and 0V

separated!

If ground and 0V is connected, these

filters do not work properly.

Power Supply [C1P11 –C1P12]

The 200E Series is designed to run on

either 12 VDC or 24 VDC supply

voltage.

Note! Make sure the supply power is

sourced directly from the battery, and

not

from the starter engine, as the

voltage drop over the latter is

significant.

Power Supply Requirements

The panel must be sourced with an 8-

32VDC supply. This is the “full

functionality” range.

General

Use a cable with twisted pair wires to

minimize the effect of noise on the

supply input.

Connect the cable straight from the

battery and keep the cable as short as

possible.

Use at least 1.0mm2(17 AWG) wires

for the power supply.

12 V supply

If the supply voltage is in the range 8-

16V, then the panel automatically

assumes it is on a 12 VDC system.

24 V supply

If the supply voltage is in the range

16-32 V, then the panel automatically

assumes it is on a 24 VDC system.

Alarm for Low Power Supply

The input voltage is monitored with

fixed set points. The set points are as

follows:

Installation Manual –200E Series Page 9

24 V supply

Warning: <21 V

Alarm: <18 V

12 V supply

Warning: <11 V

Alarm: <10 V

The persistence timer is fixed for all

set points at 30 sec before a warning

or an alarm.

RIO Link [C1P5 –C1P6]

DCU 210E and 208E

This is the link for the optional

expansion units RIO 210, RIO 410, RIO

425 and LSU 410.

Shield the cable in the RIO end only.

RP 210E/220E

On these panels, the RIO link is used

for the optional ambient light sensor

ALS 210, which provides automatic

adjustment of the backlight intensity.

J1939 CANbus [C1P7 –C1P9 and

C2P10 –C2P11]

Engine J1939 CANbus interface for

connection to the engine ECM,

electronic control module.

All Faults Relay [C2P1 –C2P3]

Note that the relay is activated when

there are no faults, and deactivates for

any fault.

A “fault” is defined as any new

instance in the alarm list, except

diagnostic messages graded white.

The relay has a 1 A over-current

protection on the common pin.

Relay #1 [C2P4 –C2P6]

This relay can be configured to

activate for any inbuilt function.

See the configuration manual.

The relay has a 1 A over-current

protection on the common pin.

Relay #2 [C2P7 –C2P9]

This relay can be configured to

activate for any inbuilt function.

See the configuration manual.

The relay has a 1 A over-current

protection on the common pin.

Magnetic Pickup, MPU [C4P1 –

C4P2]

The engine speed pickup is connected

here.

Pickup must be of Magnetic (sine-

wave) or digital (square-wave) type.

Frequency range: 100 HZ –10 KHz.

Amplitude range: 2Vp-p –30Vp-p

Shield the cable at the pickup end

only.

Modbus RS-485 [C4P3 –C4P5]

The DCU has an inbuilt Modbus™

interface, both on RS-485 and also on

Ethernet. The latter is known as

Modbus TCP.

Addressing wise, these are equal, and

the complete I/O list is available online

here:

Installation Manual –200E Series Page 10

Communication list

(https://docs.google.com/spreadsheet

s/d/1yE8VU858j559lCNR-

3cQeg9R78ncSFoczq0p0T2rU6o)

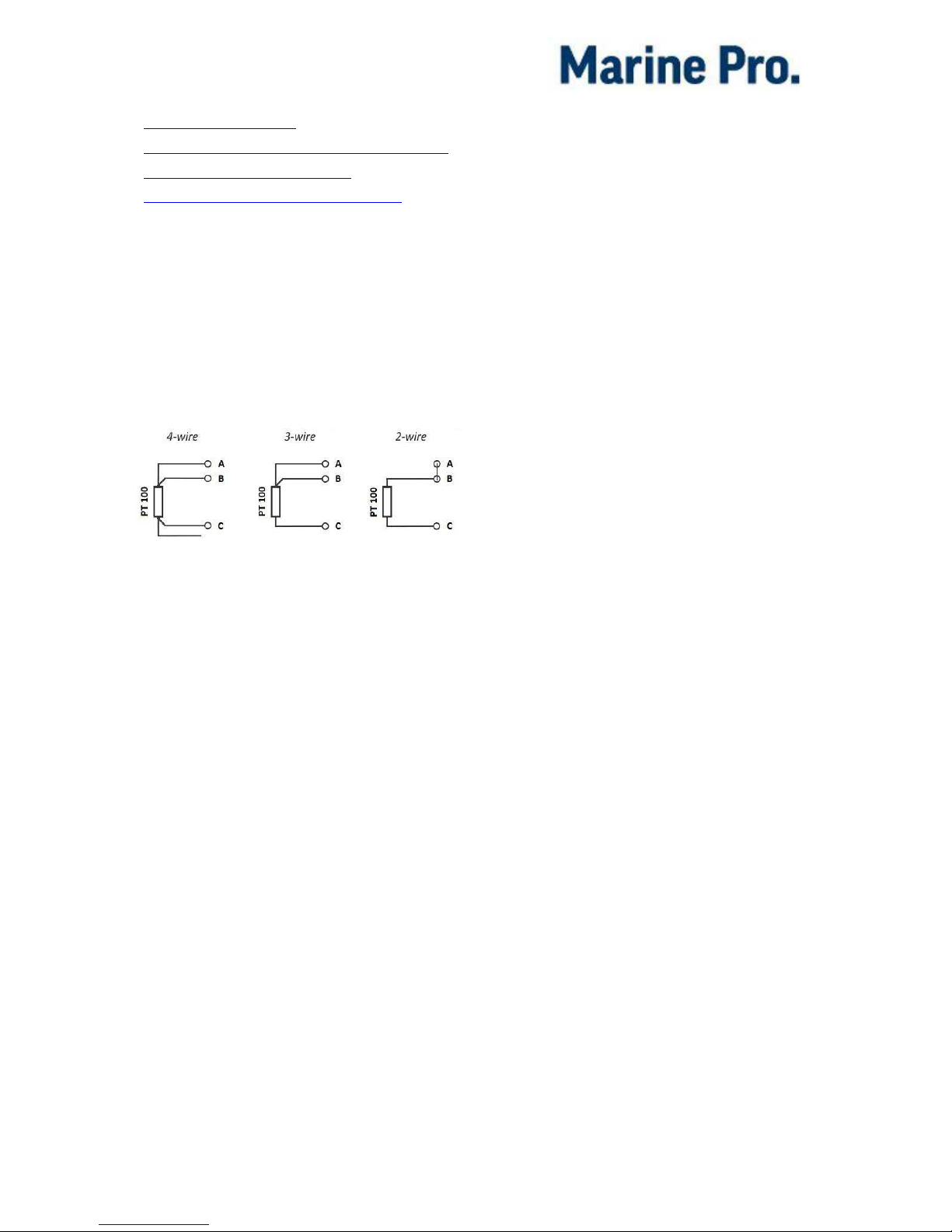

Thermistor Input [C4P6 –C4P11]

There are two thermistor input

channels on the DCU.

The channels support sensors with

two, three or four wires. See figure

below for recommended wiring

options.

Measurement range is 95 –60k ohm.

Detectable failure modes:

Broken wire between A/B and C

Short circuit between A/B and C.

Flexible I/O [I/O #1 –I/O #19]

There are nineteen Flexible I/O

channels on the DCU.

Each channel can be configured for

different use as described below.

Power Output

All flexible I/O can be configured as

12V 0,2A or 24V 0,2A power outputs

with short circuit detection and

protection.

Switched Output

All flexible I/O can be configured as

configurable 12/24V outputs on the

DCU.

Each channel can be configured for

any available function.

Voltage Sensor Input

All flexible I/O can be configured as

voltage sensor inputs on the DCU.

The voltage sensor input is capable of

measuring 0 –32 VDC.

Input impedance is 11kΩ.

4-20mA Input

All flexible I/O can be configured as

4-20 mA analog sensor inputs on the

DCU.

If the signal is out of range, a warning

will be displayed.

Out of range is defined as:

< 2 mA (broken wire)

> 22 mA (short circuit)

Note that the internal impedance is 50Ω.

Switched Input

All flexible I/O can be configured as

12/24 V input channels.

Each channel can be configured as an

engine switch, e.g. Oil Pressure Low

switch, or it can be configured to

activate an inbuilt function, eg.

Automatic Start.

Input impedance is 11kΩ.

Use the power supply voltage from

C1P11 or a configurable I/O set to

power output to power the switch

inputs.

See the Configuration manual for more

information.

Installation Manual –200E Series Page 11

Other Interfaces

Ethernet MODBUS/TCP

The DCU connects to a LAN (Local

Area Network) or directly to a PC

through a standard CAT-5 network

cable connected to the RJ45 port.

The IP address in the DCU and/or the

local PC may need to be changed in

order to access the DCU configuration

from a PC.

Note! Do not bend the Ethernet cable

or pull the cable sideways more than

necessary during installation.

Use a strain relief for the cable making

the cable length no more than 50 cm

between the connector and the strain

relief.

USB Memory Interface

This interface is used for two

purposes:

Update of the current

configuration file (not RP

panels).

Update the panel firmware (all

panels)

Copy a valid configuration and/or

firmware file to a USB memory stick,

and insert the USB memory stick in the

panel.

Follow the instructions that will be

appearing on the screen.

First Power-On

Preparations

First, make sure to consult the Quick

Installation Guide (QIG) that came with

the panel.

Installation

Install the panel according to

guidelines in the QIG.

Connections

Connect power to the panel according

to guidelines in the QIG.

First Power-On Wizard

The DCU (not DCU 208E) will display

the

first power-on wizard

at the first

power up after delivery, or after a

factory reset of the panel.

All wizard settings can be changed

later.

Installation Manual –200E Series Page 12

Appendix A

Typica l sensor connectio ns DCU 210E

This manual suits for next models

3

Table of contents

Other auto maskin Control Unit manuals