AUTOLIFT F900 User manual

-1-

1-SAFETY

Always take following safety precautions when using the Lift F900:

A-The vehicle must be parked in a flat ground. If the vehicle is parked on a slop, the use of the lift could be

dangerous.

B- The vehicle must always be safely parked, with emergency brake engaged before using the lift.

C- Always read carefully the safety instructions

D-When using the lift, the person on wheelchair must be facing outwards, meaning that the larger diameter

wheels must be turned towards the vehicle being loaded.

E- During the operations the person on the wheelchair must be in the centre of the platform, block the

parking brakes, and check that the wheels are not blocking the roll-stop and bridgeplate

F-The max load capacity is 300 KG.

G- Make sure that nobody is staying in the moving area of the lift. Always check that arms, feet, legs oder

clothes are not close to the moving parts of the lift

H- Only trained personell can operate the lift. No more people simultanously over the person on wheelchair

are allowed to be transported on the lift. Make sure that weights or persons are not staying on the platform

when it is moving IN and OUT of the Box. .

I-After the operations always return the lift in to stowage position

2- LIFT USER

The lift user hast o read this manual carefully and understand the instructions. Before starting to use the lift,

the user has to train and learn all functions without load. The user is responsible for the correct use (as

described in this manual) of the lift , for the maintanance and eventual manipulation oft he device, that could

cause hazardous conditions.

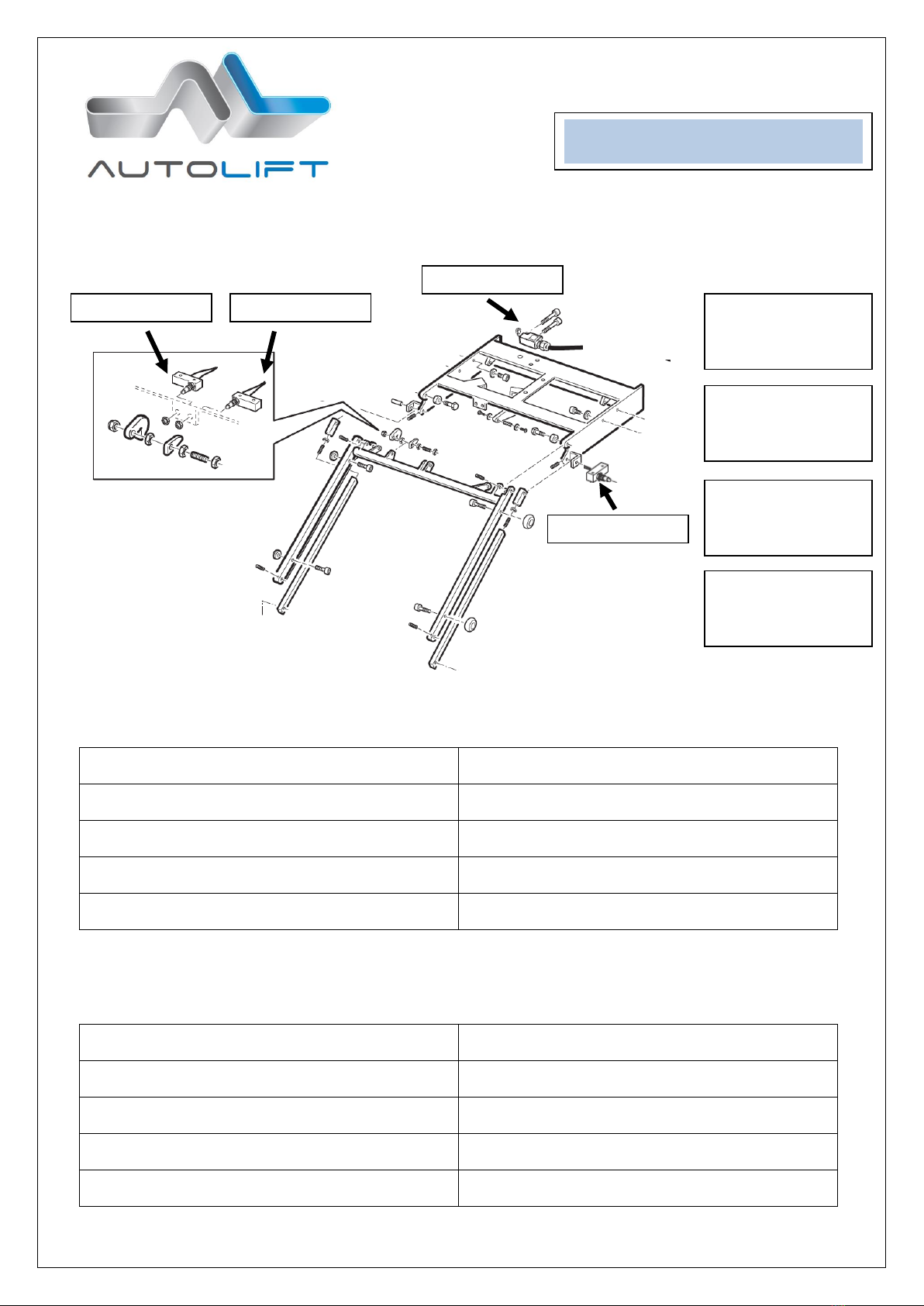

3- MAIN PARTS

Lift “F900”

Hydr. Power pack box

Electric controller box

Hand control

Aluminium Platform

Stainless Steel Box

Roll-Stop Barrier

Bridge Plate

4- HOW TO OPERATE THE LIFT

Before using the lift, the vehicle must be safely parked with emergency brake engaged and warning flashing

lights on. The operation is done through the Hand Control :

4.1 How to get in the vehicle

-Push “OUT” until the platform is completely out of the box

-Push “DOWN” until the platform is on the the ground and the roll stop is horizontal

-Wheelchair occupant gets on the platform

-Push “UP” and raise the lift up to the vehicle floor level

Wheelchair occupant gets in the vehicle

-Push “IN” , the lift will lower automatically to central position level and will stow in the box

Lift “F900”

Platform “OUT”

Platform “UP”

Platform “IN”

Platform “DOWN”

4.2 How to get off the car

-Push “OUT” until the platform is completely out of the box

-Push “UP” and raise the lift up to the vehicle floor level

-Wheelchair occupant moves from the vehicle cabin on the platform

-Push “DOWN” until the platform is on the the ground and the roll stop is horizontal

- Wheelchair occupant leaves the platform

-Push “UP” until the platform raises over the central position level

-Push “IN” , the lift will lower automatically to central position level and will stow in the box

4.3 Precautions

During the operations the person on the wheelchair must be in the centre of the platform, block the parking

brakes, and check that the wheels are not blocking the roll-stop and bridgeplate

The vehicle must always be safely parked, with emergency brake engaged before using the lift.

Make sure that nobody is staying in the moving area of the lift. Always check that arms, feet, legs oder

clothes are not close to the moving parts of the lift

Only trained personell can operate the lift. No more people simultanously over the person on wheelchair are

allowed to be transported on the lift. Make sure that weights or persons are not staying on the platform when

it is moving IN and OUT of the Box. .

When using the lift, the person on wheelchair must be facing outwards, meaning that the larger diameter

wheels must be turned towards the vehicle being loaded.

Lift “F900”

5-EMERGENCY OPERATIONS

5.1 Manual Movement of the Platform

The Platform can be manually pulled out and stowed again in the box. To operate it , just pull the

emergency wire (see Picture) that is placed in the right platform corner.

5.2 Emergency Lifting

1. Plug the lever in to the hand pump handle (Picture 1+ 2)

2. Move lever up and down

3. Using the hand pump lift the platform to the required height

4. Put the lever back in to its fixation

5. Contact an Autolift distributor or service point

Picture-1 Picture-2

5.3 Emergancy Lowering

1. Don’t remain in the area of the platform

2. Use the lever to open the lowering valve (Picture 3+4)

3. Very Slowly turn the valve clockwise and lower the platform carefully,

to the desired height. Don’t open to much otherwise the movement

could be to fast and could be dangerous

4. Close the valve by turning it anti-clockwise

Picture-3 Picture-4

Lift “F900”

Platform emergency

wire

5-EMERGENCY OPERATIONS- Version with Hydr. Unit placed under the vehicle

5.1Manual platform movement (In –Out)

The Platform can be manually pulled out and stowed again in the box. To operate it , just pull the

emergency wire (see Picture) that is placed in the right platform corner.

.

5.2 Emergency Lifting

1. Plug the lever in to the hand pump handle (Picture 1+ 2)

2. Move lever up and down

3. Using the hand pump lift the platform to the required height

4. Put the lever back in to its fixation

5. Contact an Autolift distributor or service point

Picture-1 Picture-2

5.3 Emergancy Lowering

1. Don’t remain in the area of the platform

2. Use the lever to open the lowering valve (Picture 3+4)

3. Very Slowly turn the valve clockwise and lower the platform carefully,

to the desired height. Don’t open to much otherwise the movement could be to fast and could be

dangerous

4. Close the valve by turning it anti-clockwise

Picture-3

Sollevatore “F900”

Cable for emergency

platform movement

6-CHECKS AND MAINTENANCE

6.1 CHECKS

Check before and after installation PR

The Underflor Lift F900 was previously checked in Autolift before dispatch. After Installation in to the

vehicle a trained person will have to do the described checks and confirm it on the attached Document.

In case of positive check , the lift is than approved and can be used.

It is forbidden to use the lift, if it has not been checked after installation in the vehicle.

Regular check

Beside the described checks , the lift must be checked by a trained person at least on yearly base and the

result must be confirmed in writing.

Extra Check

In case of repair or extraordinary mantainance the check must be executed by a trained person , which

work will follow anyway the regular check schematic.

Trained person

A person that with know-how and experience, that is in a position to evaluate the condition of wheelchair

lifts and safety of the users.

.

Necessary Checks

Result

-

-

-

-

-

-

-

-

-

-

Handcontrol is good condition and wire is not damaged

Fixing supports are well mounted , correctly fixed and in good conditions

All screws are well tighned

Bearings are well mounted and in the right position

Platform can freely move and no parts interfear with its movements

Bridge plate works correctly and can move freely

Bridge plate is horizontal when platform is at vehicle floor level

The Roll- Stop plate works correctly and moves freely when platform is on the

ground

Hydraulic cylinders and pipes do not show any leackage

Hydraulic pipes are not damaged

Lift “F900”

6.2 SETTINGS

By changing the position of the cams it is possible to re-set the central position level and the upper position

(vehicle floor level)

CENTRAL POSITION –Microswitch A

Platform too HIGH

Platform too LOW

A.Drive platform out of box

A. Drive platform out of box

B.Lower the Lift

B.Raise the Lift

C.Knock lightly the Cam A from the top (max 1mm)

C. Knock lightly the Cam A from the bottom (max

1mm)

D.Stow the lift back in the box (lift over central

position an than push button “in”

D. Stow the lift back in the box (push button “in”)

UPPER POSITION –Microswitch B

Platform too HIGH

Platform too LOW

A.Drive platform out of box

A. Drive platform out of box

B.Lower the Lift

B.Raise the Lift

C.Knock lightly the Cam Bfrom the top (max 1mm)

C. Knock lightly the Cam B from the bottom (max

1mm)

D.Stow the lift back in the box (lift over central

position an than push button “in”

D. Stow the lift back in the box (push button “in”)

MICROSWITCH A

regulate the central

position level

MICROSWITCH B

regulates the upper

position level

Lift “F900”

MICROSWITCH C

gives signal of lift

completely “stowed”

MICROSWITCH D

gives signal of lift

completely “out”

Microswitch A

Microswitch B

Microswitch C

Microswitch D

6.3 POSSIBLE FAILURES

First check that the battery level is acceptable

Failure

Ev. Cause

Solutions

1.Platform does’t get out of box

1.Hand control not working

2.Microswitcht A is not working

1.Check hand control and ev.

change it

2.Move manually the microswitch

pin

2.Platform is on the floor and

doesn’t raise

1.E-Motor Relais / Hand control

not working

2. Platform is accidentally been

pushed back in box

1. Check parts and change them

2. Push “out” or pull manually the

platform back entirely out from

box

3. Platform doesn’t lower

1. Hand control not working

2. Lowering valve is not working

1. Operate the lift manually and

change as soon as possible the

parts

4.Platform doesn’t lower and stow

from upper position

1. Microswitch D doesn’t work –

pin is blocked

1.Move the Microswitch pin until it

works again

7- NEW FUEL TANK

A new vehicle tank will be built, in order to reach the necessary clearance from the ground

While refueling do not overfill the tank.

Please note that the fuel level indicator of the vehicle is not precise anymoret.

Therefore use the tachometer to calculate the total or remaining km autonomy.

This way you will prevent unexpected stops because of missing fuer and unuseful service costs

Lift “F900”

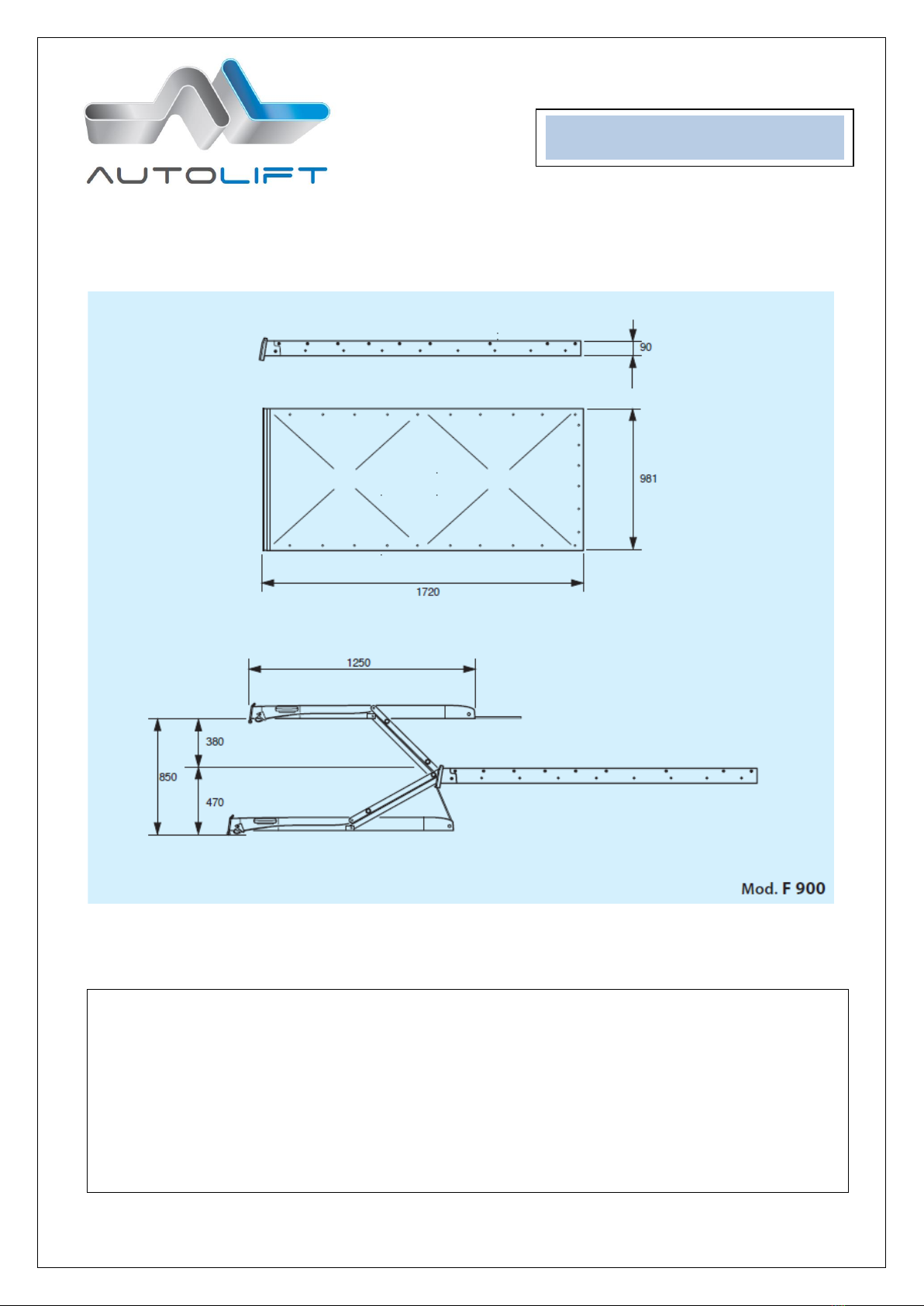

8- TECHNICAL DATAS

TECHNISCHE DATEN

TECHNICAL FEATURES

Model:

F900

Model:

F900

Tragkraft:

300 Kg

Loading capacity 300Kg

Eigengewicht:

135Kg

Weight:

135Kg

Spannung:

12 Volt

Electrical System: 12 Volt

Oeldruck max:

200 Bar

Max Air Presure: 200 Bar

Piattaformgroessen:

800 x 1250mm

Platform Dimension: 800 1250

Hubhoehe:

850mm.

Max.Floor Height: 850mm

Notpumpe und Notabsenkventil

Emergency auxiliary manual pump.

Lift “F900”

9 -HYDRAULIC DIAGRAM

The hydraulic unit is built in a protection box and can be placed inside the vehicle in preferred position. The

emergency pump and emergency lowering valve are accessible with out removing the box cover and this

allows the user an easier use of the lift also in case of emergency and battery failure.

Lift “F900”

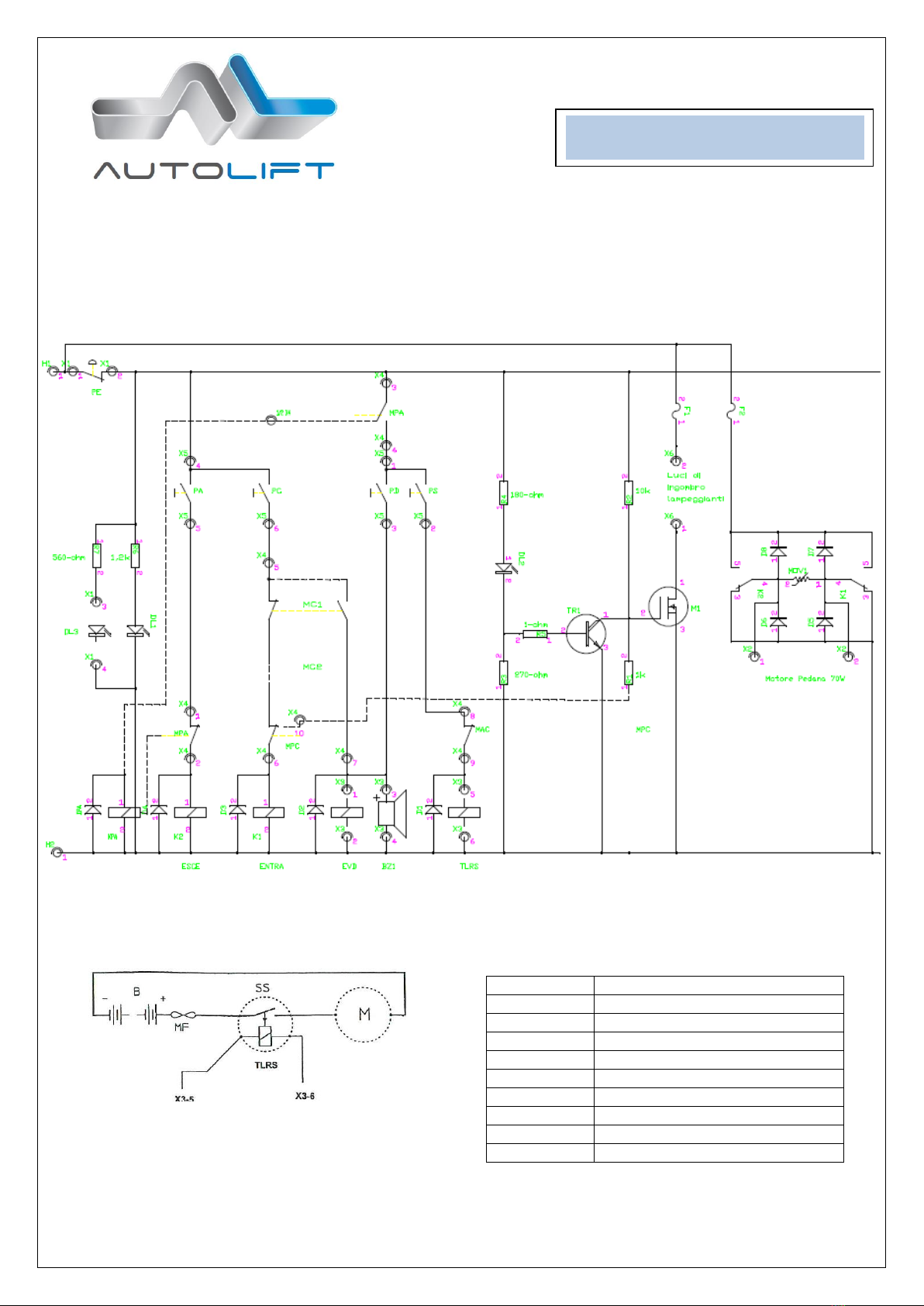

10 –ELECTRIC DIAGRAM

Control Unit (Printed circuit)

Power Unit

POSITION

CORRESPONDANCE

X2

Platform El. Motor

X6

Flashing lights

TLRS

Starting Relais

BZ1

Acustic Warning

EVB

Lowering valve

Entra

Platform in

Esce

Platform out

MC1

Microswitch for Platform Height

MC2

Microswitch for Platform Height

Lift “F900”

11 –EXPLODED VIEW

Lift “F900”

Other manuals for F900

1

Table of contents

Popular Automobile Accessories manuals by other brands

Over Armour Offroad

Over Armour Offroad CA-MAVERICKX3-4-TC01 Instructions for Installation and Care

Feniex

Feniex T3 instruction manual

DoubleTake

DoubleTake SeatBack Plates installation instructions

Metra Electronics

Metra Electronics 99-5800 installation instructions

Aim

Aim X90BGGK12MA user manual

Boyo Vision

Boyo Vision VTC1743M user manual

AL-KO

AL-KO G&S Chassis Caravan Warranty and Service Hand book

ICI

ICI Alumilite Steps 840121412920 Direction for Installation and Use

Dakota Digital

Dakota Digital BIM-16-1 manual

Kensington

Kensington K33440US Instruction guide

Brodit

Brodit 804741 ProClip installation instructions

Rhino-Rack

Rhino-Rack RCP58-BK manual