Getting Started

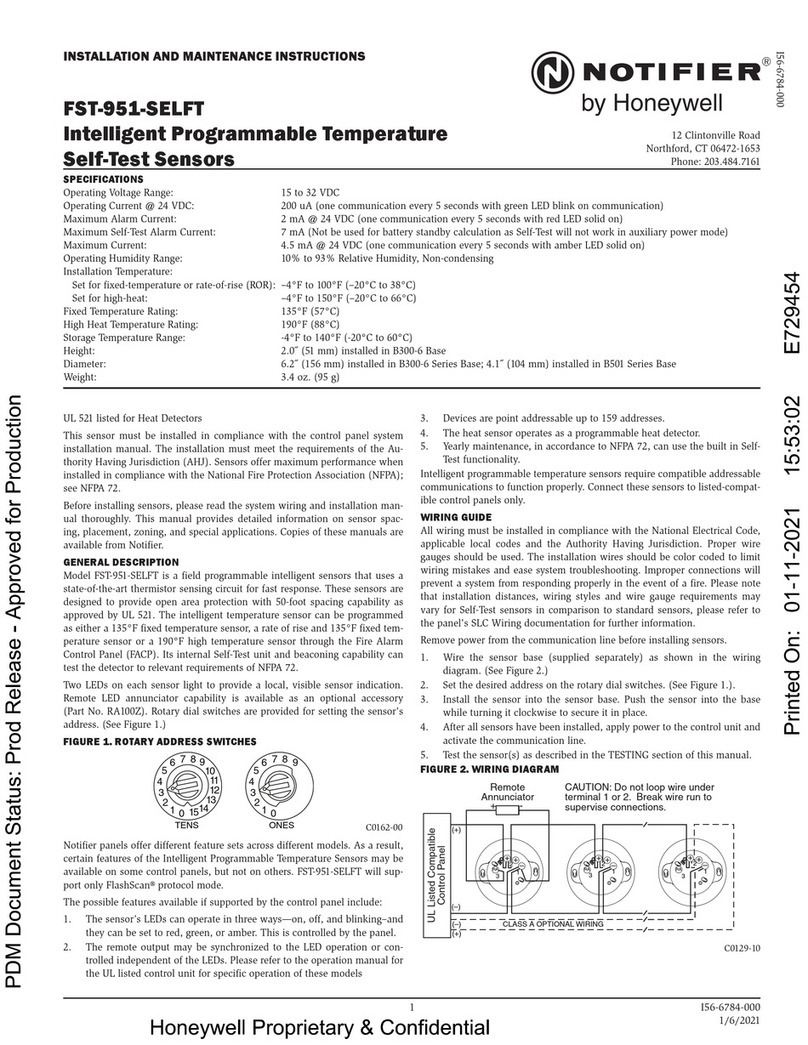

1. The Bath sensor (if used) is plugged-into the “Control” TC port, and

the thermocouple built-into the heated Perfusion Pencil™ manifold or

QuickStage™ heated perfusion chamber (with brown wire) connects

to the “Safety” TC jack. The blue LED display (left) shows the bath

temperature. The red display (right) is the safety temperature. If

you do not wish to use the bath sensor, then it should be unplugged.

Then the ThermoClamp will keep the Pencil or chamber at the set

temperature using only their internal sensor.

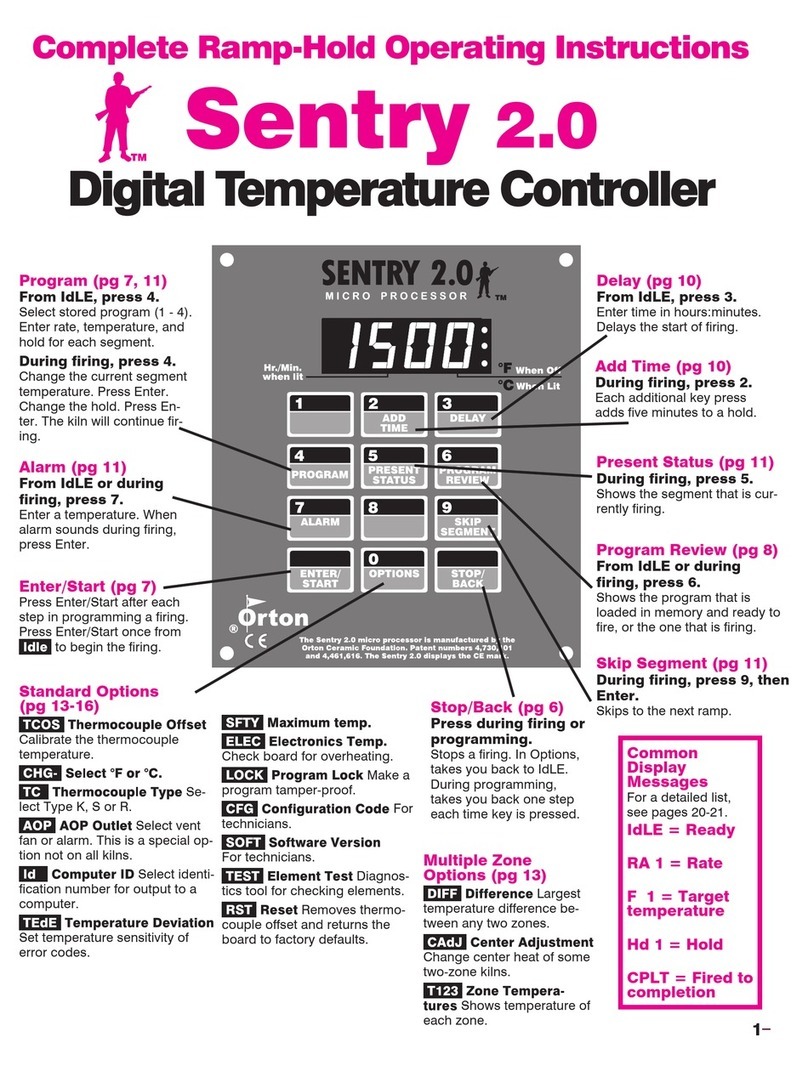

2. Set your desired temperature digitally or with the analog voltage input

BNC connector. To set it digitally, press the “Set” button once, briey,

and the “Setpoint” LED will illuminate. Use the left, blue display to

set your desired temperature. Click or hold the Up or Down buttons

until the desired setpoint is displayed. If you don’t press anything for

a few seconds, then the green light will turn o and the blue display

will show the actual bath temperature again. The maximum setpoint is

65˚C.

3. You can also use the analog input with a voltage from your computer

to set the setpoint. This input uses 20 deg C/V. Therefore, give the

ThermoClamp’s BNC input a voltage of +1.6 V for a 32˚C setpoint.

Then you can also use your computer to change it.

4. Since it has both digital and analog setpoints, the ThermoClamp auto-

selects which one to use. If you don’t connect anything to the analog

input, then the controller will use the digital setpoint. If you connect

an analog voltage to the input, then the controller automatically uses it.

It is possible to override this automatic selection by selecting “Digital”

or “Analog” setpoint mode in the settings menu (see settings menu

section for details). You will see the displays update briey when the

mode changes. The system defaults to “Auto”.

5. One of the cool features of the ThermoClamp controller is thermal

runaway protection. If you are using a bath temperature sensor

and you turn your perfusion ow o, then the bath will start to get

cold. Previous controllers will try to increase the stage or inline

heater temperature, but the bath temperature will continue to

drop. This is called “thermal runaway.” This is why our heaters

all include a Safety sensor - so they will only increase to about 75˚C

before they stop heating any further. While this may protect the

12