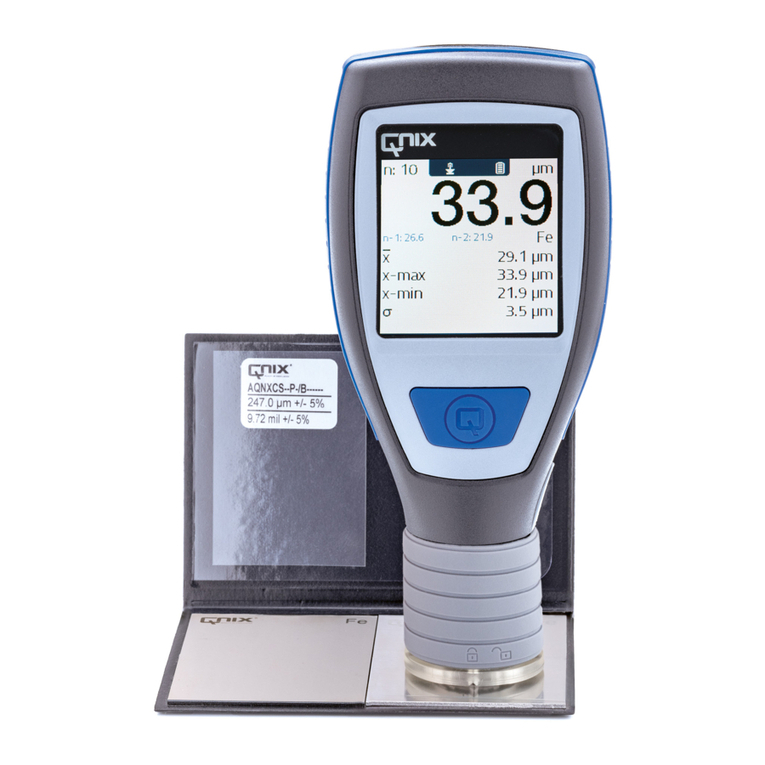

Automation Dr. Nix QNix 1500 User manual

1

Instruction Manual

Coating Thickness Gauge

1500

Optionally with Memory

Introduction

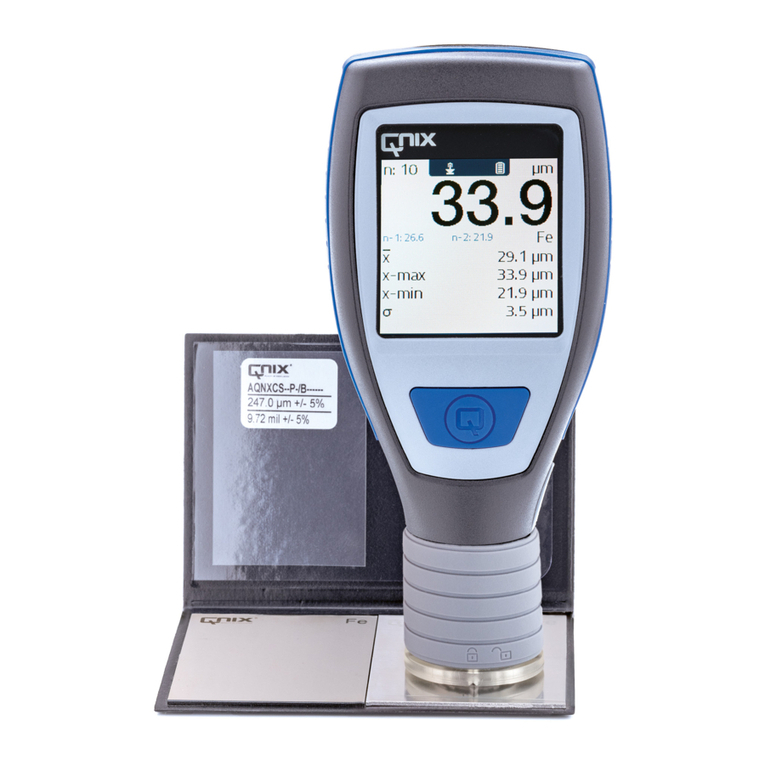

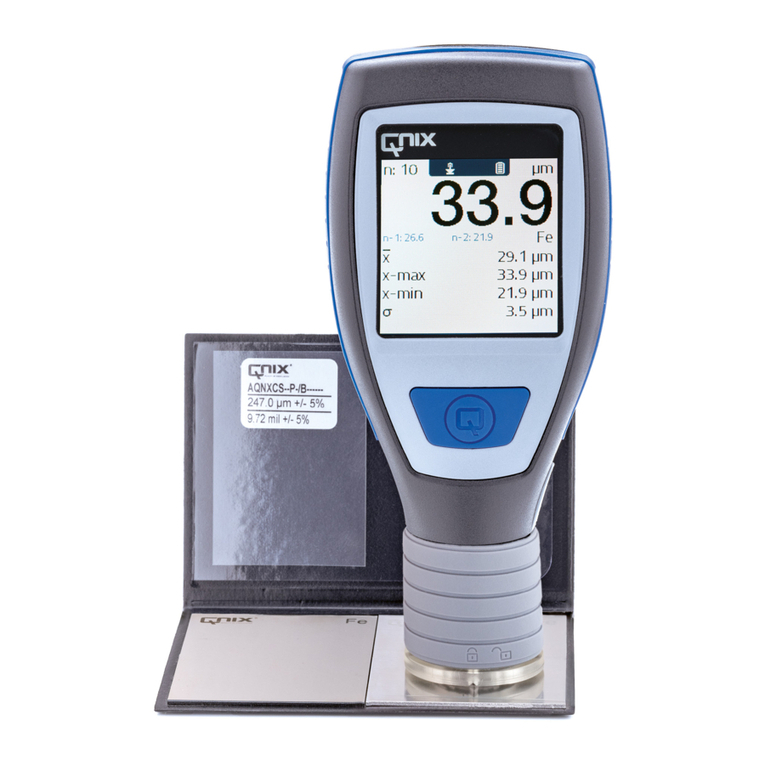

The QNix®1500 is a part of the product line of non-destructive

coating thickness measurement gauges manufactured by

Automation Dr. Nix GmbH & Co. KG in Köln, Germany.

Designed for the future, this gauge is characterized by its

many applications and wide measuring range of up to 5 mm. It

is also characterized by its robust construction as well as by

other advantages already known from our other gauges. An

ON/OFF switch is not necessary, no time-consuming

calibration routines are required, and exchange of probes is

not necessary.

The special design of this gauge facilitates measurements in

hard-to-reach corners, even more so because of the duplex

display and the memory for the last measured value.

Please read these instructions carefully before operating the

gauge for the first time. It will help you to make use of all the

advantages and conveniences this gauge offers.

Would you like information on the other gauges in our coating

thickness measurement line or do you have any questions

concerning coating thickness measurement? Please do not

hesitate to contact us. Our specialists with their long-standing

experience will be happy to assist you.

System Description

The QNix®1500 is a combination coating thickness gauge,

optionally available with memory and interface RS 232. Two

non-wearing probes, Fe-probe and NFe-probe have been

integrated in the housing.

The Fe-probe measures all non-magnetic coatings such as

lacquer, plastic, enamel, chromium, copper, zinc, etc. on steel

or iron. The NFe-probe measures all insulating coatings such

as lacquer, plastic, enamel, etc. on non-magnetic, metallic

substrates, i.e. aluminum, copper, brass or stainless steel.

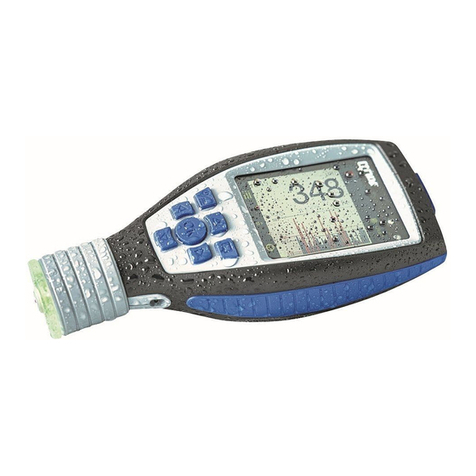

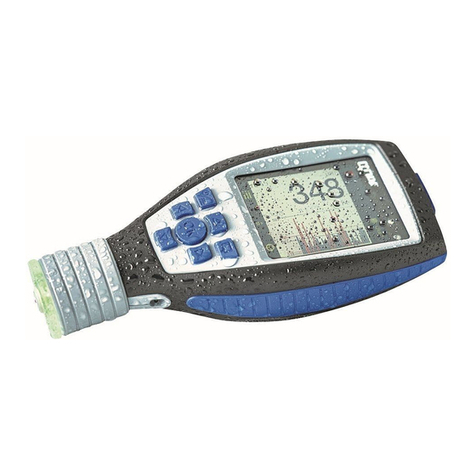

This compact design without cables and plugs allows for easy

and comfortable one-hand operation thus increasing the

working safety under rough conditions.

The QNix®1500 with memory can store the measurements

taken and even subdivide them into blocks. All in all, up to

2

3900 values can be stored and statistically evaluated.

Optionally, a special software for statistical evaluation can be

supplied.

The QNix®1500 complies with national (DIN) and international

(ISO, BS, ASTM) standards and regulations: DIN 50981,

50984; ISO 2178, 2360, 2808; BS 5411(3, 11), 3900 (c, 5);

ASTM B499, D1400, D7091

Maintenance and Handling

This gauge incorporates the latest electronic technology in

order to fulfill different measuring tasks. This high precision

instrument covers a wide range of applications, yet it is robust

and easy-to use in every-day practice. If operated and treated

with care, it will serve you many years.

Do not let it drop and protect it from dirt, dust and other

substances. After use, the gauge should be stored in its

protective carrying case.

Substantial changes in temperature can influence the

readings, as it is the case with all precision gauges. Do not

expose the gauge to strong, direct sunlight or to other sources

of energy causing temperature shocks.

Protect the gauge from moisture, chemically aggressive

substances and/or gases.

The casing is resistant against most solvents. However, a

resistancy against all chemical substances cannot be

guaranteed. Use only a damp, soft cloth to clean the casing.

Accurate readings can only be obtained, if the measuring

probes are clean. Check the probes regularly and remove

existing residues such as lacquer etc. from the ruby probe tip.

If the gauge will not be used for a long period, remove the

battery in order to prevent leakage and therefore destruction

of the gauge.

In case of a malfunction, please do not try to repair the gauge

yourself. Our repair service will be glad to help at any time.

Measuring Range

0 – 5000 μm or 0 – 200 mil in one measuring range

Gauges without memory can be switched from μm to mil by

operating the two switches on the sides of the instrument.

3

While there is a value visible on the display, push both slides

simultaneously forward and hold for more than one second.

The reading will change to the other dimension.

Gauges with memory can be switched from μm to mil using

the optionally available software.

Resolution

0.1 μm in the range of 0.0 – 99.9 μm

1 μm in the range of 100 – 999 μm

0.01 mm in the range of 1.00 – 5.00 mm

Or

0.01 mil in the range of 0.00 – 9.99 mil

0.1 mil in the range of 10.0 – 99.9 mil

1 mil in the range of 100 – 200 mil

Temperature Range

0 °C - 50 °C or 32 °F - 122 °F

Operating and Changing of Battery

The gauge is powered by a 9V alkaline battery. The battery is

located at the wide end of the gauge. If the blinking sign ”BAT“

appears on the display, it is advisable to change the battery,

but it is still possible to measure for some time. Memorized

data will remain stored, even while changing batteries.

Empty batteries should be disposed separately. If possible,

use the special services provided by your council.

Adjustment and User Information

A new zero-adjustment is required when using the gauge for

the first time, working with different materials, after inserting a

new battery, or from time to time.

Place the respective probe of the QNix® 1500 on one of the

zero plates enclosed in the case. For measurements on

ferrous substrates use the steel zero plate, for non-ferrous

applications the aluminum plate or a respective uncoated

substrate.

4

Hold the gauge according to the drawing and slightly press the

probe onto the surface so that the ring around the probe is

evenly placed. If the value indicated on the zero plate or on

your uncoated substrate is not within the basic tolerance, the

gauge should be adjusted (gauges with a memory must not be

in the Memory Mode). Push one of the slides at the sides of

the gauge while the probe is placed firmly on the substrate, i.e.

the zero plate. You will hear a ”Beep“ and a control number

will appear on the display. Lift the gauge at least 25 mm or

one inch from the zero plate. The gauge will ”beep“ again and

another number will be displayed. The QNix® 1500 is

adjusted now.

When repeating measurements on the same spot, the

measured value may not always be 0.00, due to surface

roughness, dirt, scratches etc.

The gauge is delivered with two protective rings around the

probe for better positioning and protection. These rings can

easily be removed by slightly turning and pulling. On concave

surfaces remove the protective rings in order to achieve

accurate measurements.

Measurement

Place the QNix®

1500 with its ring

around the probe

plane on the

object to be

measured (see

drawing). For

measurements on

steel or iron, the

Fe-sticker should

face you. For

measurements on

non-magnetic metallic substrates such as aluminum you

should be able to see the NFe-sticker.

Do not place your finger on the upper probe, otherwise the

readings will not be correct. Take care that the circular probe

ring is placed evenly on the surface. On even objects, the two

rear supporting points will help to position the gauge. The

5

measured value is immediately indicated on the display

accompanied by a ”Beep“.

The display shows ”ERR“ (error) if the QNix® 1500 is placed

incorrectly and ”INFI“ (infinite) if the measurement is out of

range. The same will be displayed, if measurements on non-

metallic substrates are taken. The gauge turns on

automatically and shuts off after approx. 10 sec., if it is not

used.

When measuring on rod materials remove the red ring and

align the ”V“-groove in the ring of the probe with the rod.

Do not take measurements on magnets. Magnetic fields are

likely to influence the readings with the Fe-probe. Strong

electromagnetic fields may influence all measurements.

Memorizing Measured Values

Optionally, the QNix® 1500 can be delivered with a built-in

memory and an interface RS 232C, offering the following

features:

a) Memory for up to 3900 values

b) Block segmentation up to 999 blocks

Block No. 1 Indication b001

Block No. 2 Indication b002 as up to

Block No. 999 Indication b999

c) Display of the calculatory average value in each block

d) Display of the maximum value in each block

e) Display of the minimum value in each block

f) Deleting the last measured value and the entire memory

g) Processing the measured values using interface and

software

Memory Mode (optional)

To work in the Memory Mode, the gauge has to be switched

on (take any measurement). Push both slides on the sides of

the gauge simultaneously and hold them for approx. 1 second.

Let the slides go. The display will show ”bloc“ alternating with

”b001“. The gauge is now in the Memory Mode and all

following measurements will be stored in Block 1.

Measurements in the Memory Mode will be accompanied by

6

a double ”Beep“ and the value will be displayed. After approx.

1 second, the display changes and gives you the number of

the measurements just taken. Both readings will be displayed

alternately, e.g. the display will show N 14 (number of

measurement) and 124 μm (last measured value).

To leave the Memory Mode, push both slides simultaneously

and very shortly.

Do not hold.

The built-in memory can store up to 3900 measurements. In

case the memory capacity is limited, the display will show

”END“ for approx. 6 seconds. After this, you will see the last

measured value alternating with the number of this

measurement.

If no measurements are taken within 30 seconds, the gauge

will switch off. The gauge will automatically return to Normal

Mode when started again.

Block Segmentation within the Memory

Mode

It is possible to store the measuring values in different blocks,

in order to distinguish the different tasks. To set up a new

block, e.g. Block 2, push both slides simultaneously forward

and hold them until you see the display changing. Let the

slides go. Accompanied by a ”Beep“, the display will show

”bloc“ alternating with b002. Now you have created a new

block and all following measurements will be stored in Block 2.

Other blocks can be created using the same procedure.

The sizes of the blocks may vary as they are determined by

the user only. Within the total capacity of the memory up to

999 blocks can be built. If the memory runs out of space, the

information ”End“ will be shown.

Display of Mean, Maximum and Minimum

Values

Additionally, the gauge can display the mean, maximum and

minimum value of the measurements taken in the presently

used block, if the gauge is switched on and working in the

Memory Mode. Push one of the slides for approx. 1 second

7

and let it go. Immediately, you will see the letters ”AE“ for

”Average“ and a number giving you the number of all

measurements in the respective block. This information is

followed by the display of ”μm“ or ”mil“ and the value itself,

representing the average or mean value of all measurements

taken in the present block. For example, “AE 22” alternating

with “139 μm” means, that in the active block 22

measurements have been taken and stored and that the

average value is 139 μm.

In order to see the maximum value of the active block, again

push one of the slides forward. The display will show and

the maximum value. Pushing one of the slides forward again

you will receive the minimum value of the active block. In

order to leave this mode push one of the slides forward again

or take a measurement.

In case no measurements have been taken in the active block,

it is not possible to get any statistical value. The display will

then read ”AE“. Then the gauge automatically returns to the

memory mode.

Deleting Measured Values

While operating in the Memory Mode, the QNix® 1500 offers

the possibility to delete the last reading on the display and in

the memory as well as the entire memory. To achieve this,

push one of the slides for longer than 3seconds. The last

reading will be deleted. If the slide is held further on the

display shows ”dEL“ and ”ALL“ (alternating) for 3 seconds and

a ”Beep“ sounds. If the slide is not released within these 3

seconds the entire memory will be deleted.

In case all values in a block are already deleted, the next

deleting process will eliminate the block itself, and the last

measurement in the previous block will be displayed.

The entire memory can also be deleted by use of our

optionally available software.

Processing of Memorized Values

The built-in interface RS 232 allows transfer of the data to a

PC to process the measured data statistically. The respective

plug is mounted on one side of the gauge. A software for

8

statistical evaluation on your PC is optionally available.

For further information concerning ”Data Processing“ please

refer to the software.

Possible Display Information

1. Fe = Measurement on steel or iron substrates

2. NFe = Measurement on non-ferrous metallic substrates

3. ERR = Incorrect handling

4. INFI = Incorrect substrate, e.g. measuring beyond the

measuring range or measuring on wood

5. BAT = Battery is getting weak, please exchange.

Information: the measured values will remain

stored.

6. bloc = Displayed alternating with the block number

7. End = Memory or block capacity out of space

8. N = a) alternating with Fe or NFe

= number of measurements

b) alternating with Ae

= number of measurements of the active block

9. Ae = Average value measured in the active block

10.= Maximum value measured in the active block

11.= Minimum value measured in the active block

Accessories

The electronic coating thickness gauge QNix® 1500 is

delivered with a carrying case containing Fe and NFe zero

plates, a 9 V alkaline battery, two probe protection rings and

Instruction Manual.

9

Technical Data

Substrate Fe: steel or iron

NFe: non-ferrous metallic substrates as

aluminum, zinc, copper, brass,

stainless steel

Measuring Range 0.0 – 5000 μm or 0.00 – 200 mil

convertible by slide or by software

Display of Values from 0.0 – 999 in μm

from 1.00 – 5.00 in mm

or from 0.00 – 200 in mil

Resolution 0.1 μm in the range of 0.0 – 99.9 μm

1 μm in the range of 100 – 999 μm

0.01 mm in the range of 1.00 – 5.00 mm

or 0.01 mil in the range of 0.00 – 9.99 mil

0.1 mil in the range of 10.0 – 99.9 mil

1 mil in the range of 100 – 200 mil

Repetitive accuracy ± (1 μm + 2% of reading) in the range

of 0 – 999 μm

+ 3.5% of reading in the range

of 1000 – 5000 μm

Minimum object size 10 x 10 mm2or 0.4" x 0.4"

Minimum curvature 5 mm convex or 0.2"

25 mm concave or 1.0"

Minimum substrate Fe: 0.2 mm or 8 mil

thickness NFe: 0.05 mm or 2 mil

Temperature range storage –10°C – 60°C (14°F – 140°F)

operating 0°C – 50°C (32°F – 132°F)

Display Digital (LCD)

Probes One-point, integrated

Power supply 9 Volt E block alkaline

Dimensions 166 mm x 64 mm x 34 mm

incl. probes (6.5" x 2.5" x 1.3")

Weight 130 g (4.6 oz) incl. battery

Optional: Memory capacity up to 3900 values

Blocks up to 999

Interface RS 232

10

11

03/09

12

Automation Dr. Nix GmbH & Co. KG

Robert-Perthel-Str. 2

50739 Köln, Germany

Tel. +49 (0) 221 91 74 55-0

Fax +49 (0) 221 17 12 21

www.automation.de

Table of contents

Other Automation Dr. Nix Measuring Instrument manuals

Automation Dr. Nix

Automation Dr. Nix QNix 4200 User manual

Automation Dr. Nix

Automation Dr. Nix QNix 7500 User manual

Automation Dr. Nix

Automation Dr. Nix QNix 8500 User manual

Automation Dr. Nix

Automation Dr. Nix QNix 5500 User manual

Automation Dr. Nix

Automation Dr. Nix QNix 9500 Series User manual

Automation Dr. Nix

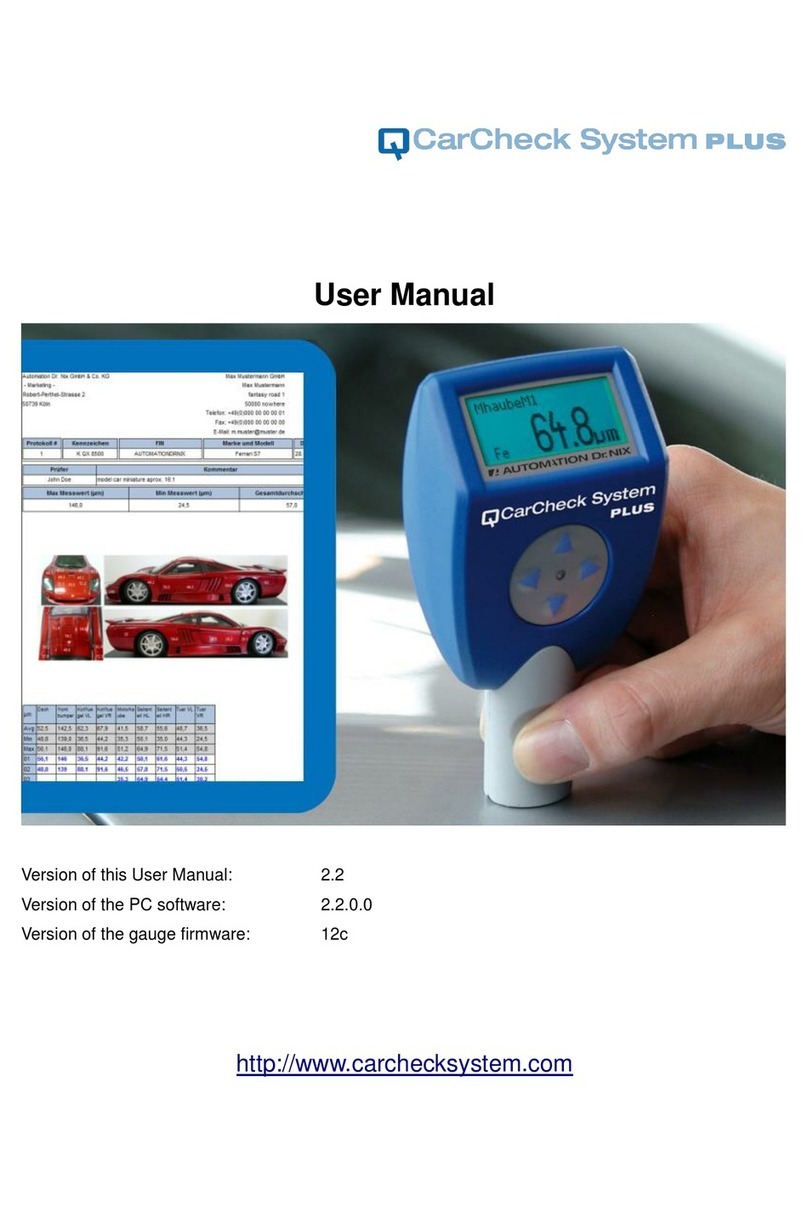

Automation Dr. Nix CarCheck System PLUS User manual

Automation Dr. Nix

Automation Dr. Nix QNix 5500 User manual

Automation Dr. Nix

Automation Dr. Nix QNix 5500 User manual

Automation Dr. Nix

Automation Dr. Nix QNix 9500 Series User manual

Automation Dr. Nix

Automation Dr. Nix QNix 9500 Series User manual