AutomationDirect OP-406 User manual

OP-406

Indicator/Pushbutton

Panel

Manual NumberOP-406-M

WARNING

Thank you forpurchasing automation equipment fromAutomationdirect.comä.WewantyournewDirectLOGICä

automation equipment to operatesafely.Anyone who installsorusesthisequipmentshouldread thispublication (and

anyother relevantpublications)beforeinstalling oroperating the equipment.

Tominimizethe risk ofpotentialsafetyproblems,you shouldfollowall applicablelocaland nationalcodesthatregulate

the installation and operation ofyourequipment. Thesecodes varyfromarea to area and usually change withtime. It is

your responsibilityto determine whichcodes should be followed,and toverifythat the equipment, installation,and

operation isincompliancewiththe latestrevision of thesecodes.

Ataminimum,you shouldfollowall applicablesectionsof the NationalFireCode,NationalElectricalCode,and the

codesof the NationalElectricalManufacturer’sAssociation (NEMA).Theremaybe localregulatoryorgovernment

officesthatcan also help determine whichcodesand standardsare necessaryforsafeinstallation and operation.

Equipmentdamage orseriousinjuryto personnelcan result fromthe failuretofollowall applicablecodesand

standards.We do notguarantee the productsdescribed inthispublication aresuitableforyourparticularapplication,

nordo we assume anyresponsibilityforyourproductdesign,installation,oroperation.

If you have anyquestions concerning the installation oroperation of thisequipment, orifyou need additional

information,pleasecall usat770--844--4200.

Thispublication isbased on information thatwasavailable at the timeitwasprinted.AtAutomationdirect.comäwe

constantly strivetoimprove ourproductsand services,sowereservethe right tomakechangestothe productsand/or

publicationsatanytimewithoutnotice and withoutanyobligation.Thispublication mayalso discuss featuresthatmay

notbe availableincertainrevisionsof the product.

Trademarks

Thispublication may containreferencesto productsproduced and/oroffered byothercompanies.The productand

companynamesmaybe trademarked and arethe sole propertyof their respective owners.Automationdirect.comä

disclaimsanyproprietaryinterestinthe marks and namesofothers.

Copyright1999,Automationdirect.comäIncorporated

All RightsReserved

No partof thismanualshall be copied,reproduced,ortransmitted in anywaywithout the prior,written consentof

Automationdirect.comäIncorporated.Automationdirect.comäretainsthe exclusiverightsto all information

included inthisdocument.

1

M

a

n

u

a

l

R

e

v

i

s

i

o

n

s

If you contactusinreferencetothismanual,be sure and include the revision number.

Title:OP--406 SetpointPanel User Manual

ManualNumber:OP--406--M

IssueDateEffective Pages Description ofChanges

Original8/99 All OriginalIssue

1

E

U

I

n

f

o

r

m

a

t

i

o

n

Thisproductismanufactured incompliancewithEuropean Union (EU)Directivesand carriesthe CE

mark.The following information isprovided tocomplywithEUdocumentation requirements.

NOTE:ProductswithCEmarks perform their required functions safelyand adhere

torelevantstandardsas specified byEUdirectivesprovided theyare used

according totheirintended purpose and that the instructionsinthismanualare

adhered to.The protection provided bythe equipmentmaybe impaired if this

equipmentisused in a mannernotspecified inthismanual. Onlyreplacementparts

supplied byAutomationdirect.comoritsagents should be used.Alisting of

internationalaffiliatesisavailable atourWeb site:www.automationdirect.com.

If you need technicalassistance,pleasecall the technicalsupportgroup at

Automationdirect.com(3505 Hutchinson Rd., Cumming, GA30040,U.S.A.)at

770--844--4200.Theyare availableMondaythrough Fridayfrom9:00 A.M. to 6:00

P.M.EasternStandardTime.The Web Site address is

www.automationdirect.com.

All electricalcircuits connected tothe communicationsportreceptacle arerated as

SafetyExtra LowVoltage (SELV).

Operating Temperature 0°to 50°C.....................

Storage Temperature--20°to 70°C......................

Operating Humidity95%(non-condensing)........................

AirComposition Nocorrosive gasespermitted...........................

No preventativemaintenanceisrequired.Toclean the exteriorof the panel

disconnect the inputpowerand carefullywipe the panel with a clothmoistened with

plainwater.

There arenointernalfusesforthe inputpowercircuits,so externalcircuitprotection

isneeded to ensurethe safetyofservice personneland the safe operation of the

equipmentitself. TocomplywithEUspecifications, the inputpower mustbe fused.

Useafuserated attwice the inputcurrentrating of the panel.Forexample,if the

panelhasan inputcurrentrating of0.5 amperes,useafuserated for1 ampere.

TechnicalSupport

SELVCircuits

Environmental

Specifications

Preventative

Maintenance and

Cleaning

E

x

t

e

r

n

a

l

F

u

s

e

Protection

forInputPower

1

i

TableofContents

Chapter1:Getting Started

Introduction 1--2.........................................................................

The Purpose of thisManual1--2.........................................................

SupplementalManuals1--2.............................................................

TechnicalSupport1--2.................................................................

Chapters1--3.........................................................................

ConventionsUsed1--3...................................................................

KeyTopics forEachChapter1--3........................................................

OP--406 Overview1--4...................................................................

Plan yourSystem1--4.................................................................

GeneralPanelInformation 1--4..........................................................

IndicatorLampsand Pushbuttons1--4...................................................

Back-PanelLayout1--5................................................................

Serial CommunicationsPort1--5........................................................

PowerReceptacle 1--5.................................................................

FrequentlyAskedQuestions 1--6.........................................................

Chapter2:Installation and Specifications

Labeling theLamps and Pushbuttons 2--2.................................................

Labeling the Lampsand Pushbuttons2--2................................................

Creating the Labels2--2................................................................

Creating LabelsUsing OP--WINEDIT2--2................................................

Templates forManuallyCreating Labels 2--4...............................................

DimensionsforMounting 2--5............................................................

PanelSpecifications 2--6.................................................................

PhysicalSpecifications2--6.............................................................

EnvironmentalSpecifications2--6.......................................................

Operating Specifications2--6...........................................................

PowerSupplyConnections 2--7..........................................................

PowerSupplyConnections2--8.........................................................

Connecting theConfiguration Cable 2--8..................................................

Configuration Cable 2--8...............................................................

Selecting aCommunicationsCable 2--9...................................................

CommunicationsCableDetails 2--10.......................................................

OP400 SeriesCommunicationsCables2--10..............................................

Chapter3:Understanding theFeatures

Learning theFeatures 3--2...............................................................

IndicatorLampand Pushbutton Operations 3--3...........................................

Reading Pushbutton Status3--3.........................................................

Turning on a Lamp 3--3................................................................

Flashing a Lamp 3--3..................................................................

Turning on the InsetLED3--3...........................................................

i

i

Table ofContents

PLC Registers 3--4.......................................................................

PLC RegisterOverview3--4............................................................

PLC Register Map 3--4.................................................................

ForceCommands3--4.................................................................

DirectLOGIC UserMemoryOverview3--6.................................................

Chapter4:Configuring YourOperatorPanel

Preparing forConfiguration 4--2..........................................................

OP--WINEDITSoftware 4--2............................................................

More about OP--WINEDIT4--2..........................................................

HELP Screens4--2....................................................................

ComputerSystemRequirements4--3....................................................

HowtoConfigureYourPanel4--3.........................................................

Chapter5:Programming Examples

Examples Using PLCDirectPLCs 5--2.....................................................

RegisterUsage 5--2...................................................................

Examples Using DL05,DL105,DL205,D3--350 and DL405 5--3..............................

Turning on a Lamp 5--3................................................................

Flashing a Lamp 5--4..................................................................

UsingaButton 5--4....................................................................

Lighting an InsetLED5--5..............................................................

Flashing an InsetLED5--5.............................................................

Forcing Button Status 5--6...............................................................

ForceButton Status5--6...............................................................

ForceButton(s)On 5--6................................................................

ForceButton(s)Off 5--6................................................................

ExampleUsing D3--340 5--7..............................................................

RegisterUsage 5--7...................................................................

Examples Using Allen-BradleytSLC5/03,5/04 and MicrologixPLCs 5--8....................

Interfacing toA-BMemory5--8..........................................................

Turning on a Lamp 5--8................................................................

Flashing a Lamp 5--9..................................................................

UsingaButton 5--9....................................................................

Lighting an InsetLED5--10..............................................................

Flashing an InsetLED5--10.............................................................

Forcing Button Status 5--11...............................................................

ForceButton Status5--11...............................................................

ForceButton(s)On 5--11................................................................

ForceButton(s)Off 5--11................................................................

Troubleshooting theOP-406 Panel5--12....................................................

Index

1

1

Getting Started

InThisChapter....

—Introduction

—ConventionsUsed

—OP-406 Overview

—FrequentlyAsked Questions

G

e

t

t

i

n

g

S

t

a

r

t

e

d

1

-

-

2

Getting Started

Introduction

OP-406

Howto

Usethe

Thank you forpurchasing an OP--406

OptiMate panel.ThisUser Manual

shows you howtoinstall,configure,and

programthe OP--406.Alsoincluded are

application examples.Besuretokeep

thismanualhandyfor referencewhen

you run into questions.Ifyou understand

PLCsystemsand operatorinterface

units, thismanual will provide all the

information thatyou need to getand keep

yourpanelup and running.

The OP-1500 and OP-1510

Indicator/Pushbutton Panels

maybe reconfigured to

exchange datawithyour

programmablecontroller.

The OP-1500 and OP-1510

Indicator/Pushbutton Panels

maybe reconfigured to

exchange datawithyour

programmablecontroller.

The OP-1500 and OP-1510

Indicator/Pushbutton Panels

maybe reconfigured to

exchange datawithyour

programmablecontroller.

The OP-1500 and OP-1510

Indicator/Pushbutton Panels

maybe reconfigured to

exchange datawithyour

programmablecontroller.

Referencethe appropriatePLC/CPU

user manualsforthe commandsand

address referencesrequired foryour

system. If you are using a DirectLOGIC

PLCproduct, you will want tokeep the

DirectSOFT User Manualhandywhile

programming yoursystem.Forother

PLCbrands you mustreferencetheir

user manualsto properlyprogramthe

ladderlogicrequired to operatethe

OP-panel.

Werealizethateven though westriveto be the best, wemayhave arranged our

information insuchawaythatyou cannot find whatyou arelooking for.First, check

theseresourcesforhelpinlocating the information:

STableofContents-- chapterand section listing ofcontents,inthe front

of thismanual

SQuick GuidetoContents-- chaptersummarylisting on the nextpage

You can alsocheck ouronline resourcesforthe latestproductsupportinformation:

SInternet-- the address ofourWeb siteishttp://www.automationdirect

.com

If you still need assistance,pleasecall usat770--844--4200. Ourtechnicalsupport

group will be glad toworkwithyou in answering yourquestions.Theyare available

Mondaythrough Fridayfrom9:00 A.M. to 6:00 P.M.EasternTime. If you have a

commentorquestion aboutanyofourproducts,services,or manuals,pleasefill out

and returnthe ‘Suggestions’cardthatwas shipped withthismanual.

ThePurpose of

thisManual

Supplemental

Manuals

TechnicalSupport

G

e

t

t

i

n

g

S

t

a

r

t

e

d

1

-

-

3

Getting Started

The maincontentsof thismanualare organized intothe following fivechapters:

Getting Started

Introducesthe physicaland functionalcharacteristics.

Discussesthe pushbuttonsand the LED indicatorlamps.

Also providesintroduction to planning yoursystem.

Installation and

Specifications

Showshowto prepareforsysteminstallation,including

specificationsand mounting instructions. Includes

connecting cablespartnumbersand specifications.

Understanding the

Features

Explainsthe featuresand functionsof the OP--406.Teaches

conceptofhowdataisexchanged between the paneland

the PLC.Also discussesthe function of the statusregister.

Configuring the

Indicator/Pushbutton

Panel

Showshowto usethe OP--WINEDITconfiguration softwareto

configureyourpanel.Showshowtoload the softwareonyour

personalcomputer,call up the screens you will need and howto

download the configuration programtoyourpanel.

Programming

Examples

Providesexample programsforusing the standardfunctionsand

features.These examplesinclude ladderlogicforimplementing

pushbuttonsand messagesusing DirectLOGICcompatiblesand

Allen-BradleySLC5/03,5/04 and MicrologixCPUs.Alsoincludes

troubleshooting information.

ConventionsUsed

When you see the “notepad”icon inthe left-hand margin, the paragraph toits

immediaterightwill beaspecialnote.

The wordNOTE:in boldfacewill markthe beginning of the text.

When you see the “exclamation mark”icon inthe left-hand margin, the paragraph to

itsimmediaterightwill beawarning.Thisinformation could preventinjury,loss of

property,oreven death(in extremecases).

The wordWARNING:in boldfacewill markthe beginning of the text.

The beginning ofeachchapterwill list the

keytopics thatcan be found inthat

chapter.

1

Chapters

1

2

3

4

5

Key Topics for

EachChapter

G

e

t

t

i

n

g

S

t

a

r

t

e

d

1

-

-

4

Getting Started

OP--406 Overview

Let’slookat the OP--406 Indicator/Pushbutton Paneland itsindividually supported

features.As you continue through thismanual, trytorelatethe examplestoyour

Indicator/Pushbutton Panelapplication.

It isimportant toread and understand all topics discussed beforeinstalling,

configuring and programming yourapplication.You should plan yoursystemwith all

operatorinterfacerequirementsinmind.

MACHINE

PLC

MemoryRequirements...

Process Data.....

OP--WINEDIT

The OP--406 Indicator/Pushbutton Panelprovidesaman-machine interfacetoyour

PLCautomation system.Thispanel isnotdesigned forapplicationswhich demand

large amountsofoperatordata entry.The panelcommunicateswithyourPLCusing

RS-232 serialcommunication.Detailson configuration software and programming

yourIndicator/Pushbutton Panelarecovered inlaterchapters.All OP400 series

panels can onlybe used in a stand alone fashion (one panelcan be used with each

CPU RS232 port).They cannotbe used inmulti-panelapplications.

The OP--406 Indicator/Pushbutton Panelfeatures sixLEDIndicatorLampsand four

pushbuttons.The Lamps can be controlled to be on,off orflashing.The Pushbuttons

can be configured to operate aseither momentaryoralternate action.When a

pushbutton ismomentary,itsLED insetcan indicate button statusoract

independentlyofbutton status.The OP--406 connectsto a PLC with a singlecable.

When used withaPLC,operation istransparent tothe user.Lampsand buttons

appearinthe PLCprogramas coilsand contacts.The OP--406 takes care of the rest.

PlanyourSystem

GeneralPanel

Information

IndicatorLamps

and Pushbuttons

G

e

t

t

i

n

g

S

t

a

r

t

e

d

1

-

-

5

Getting Started

The back side of the OP--406 containsaserialcommunicationsportwithtransmit

(TX)and receive(RX)LEDsand a power receptacle.

RXLED

(Green)

TXLED

(Red)

RJ12 ConnectionPowerReceptacle

Location

The serialcommunicationsportisa 6-pinRJ12 connector,whichsupportsRS-232

interfacewiring.Thisportisused forcommunicationsbetween the OP-paneland

PLC,aswell asforprogramming yourpanelconfigurations.

The OP--406 can also draw+5VDC inputpowerthrough thisport through the

communications cablewhen using a DL05,DL105,DL205 orDL405 PLC. Inthis

case, the OP--PS400 powersupplyisonlyneeded forconfiguration.

The center-negativeconnectorislocated on the side of the panel,and isused to

connect the OP--PS400 powersupply.Thispowersupplyisused when configuring

the panel.Itisalso used to powerthe panel when the panel is connected to anyCPU

thatdoesnotsupply+5VDC fromthe communicationsport.

Back-PanelLayout

Serial

Communications

Port

PowerReceptacle

G

e

t

t

i

n

g

S

t

a

r

t

e

d

1

-

-

6

Getting Started

FrequentlyAskedQuestions

Q. Whatisrequiredto getstarted using theOP--406 inmy application?

A.You mustread thismanualand understand the OP-panelrequirementsand

application concepts.You musthave programming knowledge forthe PLCproduct

you’re using, the PLCserialcommunications capabilitieswhich are available,as

well ashook-up and connecting cable data.

Q. Howdo IconfiguretheOP--406 Indicator/Pushbutton Panel?

A.Using the OP-WINEDITconfiguration software availablefromPLCDirect.This

software allows you toconfigurethe OP-panelsin a Microsoft Windowst

environment. You may configureyourprogramsoffline,upload,and/ordownload

themtoyourOptiMate panel.The OP-WINEDITsoftwareisprovided with

installation documentation and Helpscreens.

NOTE:OP--WINEDITversion 2.3 orlaterisrequired when using OP400 series

panels.

Q. CantheOP--406 beusedwith otherPLCproducts?

A.Yes.The OP400 unitsdo supportAllen-BradleySLC5/03,SLC5/04,and

Micrologix.

Q. CanIconnectmorethan oneOP--406 panelto onePLC/CPU?

A.Yes,butonlyif the CPUhasmorethan one communicationsport. OP400 series

panels can onlybe used inastand alone fashion; thatis,one panelcan be used with

one CPUport. OP600 and OP1000 seriespanels can be used inmultiple panel

applications(even if the CPUhasonlyasinglecommunicationsport)with an

OP--9001 communicationspanel.

Q. WhatarethepowersupplyrequirementsfortheOP--406?

A.The OP400 seriespanelsrequire5VDC inputpower.A5VDC externalpower

supplythatplugsintoastandard 120 VACreceptacleisavailable(partno.

OP--PS400).Thispowersupply(orequivalent, butitmusthave acenternegative

powerjack)isrequired forconfiguring yourpanel.Itisalsorequired foroperation

unless you are usingaDL05,DL105,DL205 orDL405 PLC; these products supply

5VDC through the communications cable.All otherPLCs,including DL305 CPUs

(when used withaD3--05B--1,D3--08B--1 orD3--10B--1 base),requirethe use ofan

external5VDC powersupply.

Q. Will theOP-panels supportgraphics,animation,orcoloroperatordisplay screens?

A.No, the OP-panelswhichsupportdisplay capabilitiesallownumericdata display,

and some panelswill also allowtextmessage display.

2

Installation and

Specifications

InThisChapter....

—Labeling the Lampsand Pushbuttons

—Templatesfor ManuallyCreating labels

—Dimensionsfor Mounting

—PanelSpecifications

—PowerSupplyConnections

—Connecting the Configuration Cable

—SelectingaCommunicationsCable

—CommunicationsCableDetails

I

n

s

t

a

l

l

a

t

i

o

n

a

n

d

S

p

e

c

i

f

i

c

a

t

i

o

n

s

2

-

-

2

Installation and Specifications

Labeling theLamps and Pushbuttons

Labeling the OP--406 panel isa

relatively simple process thatinvolves

removing the bezeland sliding a label

transparency into a pocketinthe panel

overlay.The transparent filmcan be

purchased fromalmostanyofficesupply

storeinstandard 8-1/2”x11”sheets. It is

designed torun through a copymachine

orlaserprinter.

The easiestwaytocreatelabelsisto usethe built-inlabelmaking function of the

OP--WINEDITconfiguration software.Thisisthe preferred method and is shown

below.The labels can alsobecreated manuallyusing the templateshowninthe next

section to helplayout the transparency film.Here aresomeways ofmanually

creating labels:

SUseacomputergraphics programand a laserprintertocreatethe

transparency directly,orprint the labelson paperand photocopythem

toatransparency sheet.

SUse press-on lettersonatransparency sheet.

SUseatypewriterorlettering machine,oruse press-on letterstocreate

labelson a papersheet, then photocopythe papersheetonto a

transparency sheet.

Making labelsusing the OP--WINEDITconfiguration softwareiseasy (see Chapter4

forinformation on loading and using OP--WINEDIT).Afterloading OP--WINEDIT,

followthesesteps:

Open OP--WINEDITand selectNewSystem.

1.

Labeling the

Lamps and

Pushbuttons

Creating the

Labels

Creating

LabelsUsing

OP--WINEDIT

I

n

s

t

a

l

l

a

t

i

o

n

a

n

d

S

p

e

c

i

f

i

c

a

t

i

o

n

s

2

-

-

3

Installation and Specifications

The OP--406 LabelTemplate appears.Type inthe labeltext forall

indicatorsand pushbuttons.Press OKtosavethe labels.

SelectOP--406,and ConfigurePanel.

2.

SelectLabels.3.

4.

I

n

s

t

a

l

l

a

t

i

o

n

a

n

d

S

p

e

c

i

f

i

c

a

t

i

o

n

s

2

-

-

4

Installation and Specifications

5.Printlabelon transparent film.

Printer

StartSetup NextPrev.

Pushbutton Template:

OM406 LabelTEMPLATES

Transparent

Sheet

6.Cutout the block oflabelsand

Bezel

Pocket

StartSetup NextPrev.

Removethe bezelfromthe module byunsnapping the fourplastictabswhich holdthe bezeltothe

moduleframe.Locatethe pocket, and carefully slide the labelsinto place.Re-attachthe bezelby

snapping the bezelontothe case.

insert theminthe panel.

Templates forManuallyCreating Labels

0.30”

1.50”

0.10”

0.05”

0.30”

0.10”

0.30”

1.50”

0.30”

1.50”

0.10”

0.05”

0.30”

0.10

”

0.30”

1.50”

IndicatorLamp Label Inserts

0.60”

4.425”

1.35”

0.10”

0.60”

1.00”0.06”

1.00”1.00”0.60”

Pushbutton Label Insert

I

n

s

t

a

l

l

a

t

i

o

n

a

n

d

S

p

e

c

i

f

i

c

a

t

i

o

n

s

2

-

-

5

Installation and Specifications

DimensionsforMounting

5.40”

5.00”

0.60”

Example panelmounting

0.50”

1.00”

CutoutArea

0.20”

0.16”DIA,

fourplaces

2.00”

3.10”

3.00”

DimensionsinInches

I

n

s

t

a

l

l

a

t

i

o

n

a

n

d

S

p

e

c

i

f

i

c

a

t

i

o

n

s

2

-

-

6

Installation and Specifications

PanelSpecifications

Weight8 ounces..................................

PanelFastenersFour6x32 threaded studs..........................

Pushbutton Dimensions0.65 in.square on 1.0in.centers....................

Pushbutton Life 1,000,000 switchcycles...........................

IndicatorLampColorsRed......................

NEMARating NEMA4(when properlyinstalled).............................

Operating Temperature 0°to 50°C.....................

Storage Temperature--20°to 70°C......................

Operating Humidity95%(non-condensing)........................

AirComposition Nocorrosive gasespermitted...........................

PowerConsumption 0.25W@5VDC.......................

(PowerOnsurge of0.35Afor1msmax.)

PowerConnectorThree terminalDC powerplug,..........................

centernegative

PowerSupply+5VDC externalpowersupplyrequired.............................

forconfiguration on all panels;required

foroperation on all PLCsexceptDL05,

DL105,DL205 and DL405.

Minimum/MaximumSupplyVoltage +5VDC only..........

Diagnostics LEDStatus...............................

Communication LinkRS-232.......................

4800 to19200 baud

6-pinRJ12 phone jack type connector

Physical

Specifications

Environmental

Specifications

Operating

Specifications

I

n

s

t

a

l

l

a

t

i

o

n

a

n

d

S

p

e

c

i

f

i

c

a

t

i

o

n

s

2

-

-

7

Installation and Specifications

PowerSupplyConnections

OP400 seriespanelsrequire+5VDC inputpower.An optional5VDC externalpower

supplythatplugsintoastandard 120 VACreceptacleisavailable(partno.

OP--PS400).Thispowersupply(orequivalent)isrequired forconfiguring your

panel.Itisalsorequired foroperation unless you are using a DL05,DL105,DL205

orDL405 PLC; these products supply5VDC through the communications cable.All

otherPLCs,including the DL305s,Allen-Bradley5/03,5/04 and Micrologix,require

the use ofan external5VDC powersupplyduring operation.

NOTE:Onlyusea5VDC powersupplythathasacenternegative DC powerjack.

Configuration:5VDC PowerSupplyRequired ForConfiguring All 400 seriespanels

5VDC PowerSupply

(PartNo.OP--PS400)

OP--CCBLConfiguration

Cable

Operation Using aD3--340,D3--350,D3--330 w/DCU,BottomPortof

DL405 orAllen-Bradley CPU:5VDC PowerSupplyRequired

Operation Using aDL05,DL105,DL205,orTop Port

ofDL405 CPU:5VDC PowerSupplyNotRequired

CommunicationsCable

Supplies5VDC InputPower

I

n

s

t

a

l

l

a

t

i

o

n

a

n

d

S

p

e

c

i

f

i

c

a

t

i

o

n

s

2

-

-

8

Installation and Specifications

5VDC (+)

Insertpowersupply connector

intoreceptacle

OP-PS400

PowerSupply

0VDC (--)

SerialPortReceptacle

Connecting theConfiguration Cable

You will need twocablesto useyourOP-panel:Aconfiguration cable(partnumber

OP--CCBL)and a communications cable.Connect the configuration cable between

the serialporton the rearof the OP-paneland the serialportof the personal

computer.The panelmaythen be configured using the OP--WINEDITconfiguration

software.The figure belowshows configuration cableconnectorsand wiring

specifications.The wiring diagram referstothe cableconnectors,notthe

communication ports.This cableisdisconnected afterconfiguration.

OP--CCBLConfiguration Cable

ComputerPanel

1=notused

2=RX

3=TX

4=notused

5=Sig ground

6=notused

7=notused

8=notused

9=notused

9

5VDC PowerSupply

3 4 5 621

1=Sig ground

2=Cfgmode

3=RX

4=TX

5=notused

6=Sig ground

RJ12

DB9RJ12

5

42

33

2

15

6

DB9

1

(Sockets)

PowerSupply

Connections

Configuration

Cable

Table of contents

Other AutomationDirect Measuring Instrument manuals

AutomationDirect

AutomationDirect ProSense DPM3-P Series User manual

AutomationDirect

AutomationDirect ProSense VFS50-5-1001 User manual

AutomationDirect

AutomationDirect ProSense DPM1-P Series User manual

AutomationDirect

AutomationDirect ProSense LPM1 Series User manual

AutomationDirect

AutomationDirect ProSense DPM3 Series User manual

AutomationDirect

AutomationDirect ProSense DPM2-E Series User manual

AutomationDirect

AutomationDirect ProSense DPM2 Series User manual

AutomationDirect

AutomationDirect ProSense DPM1 Series User manual

AutomationDirect

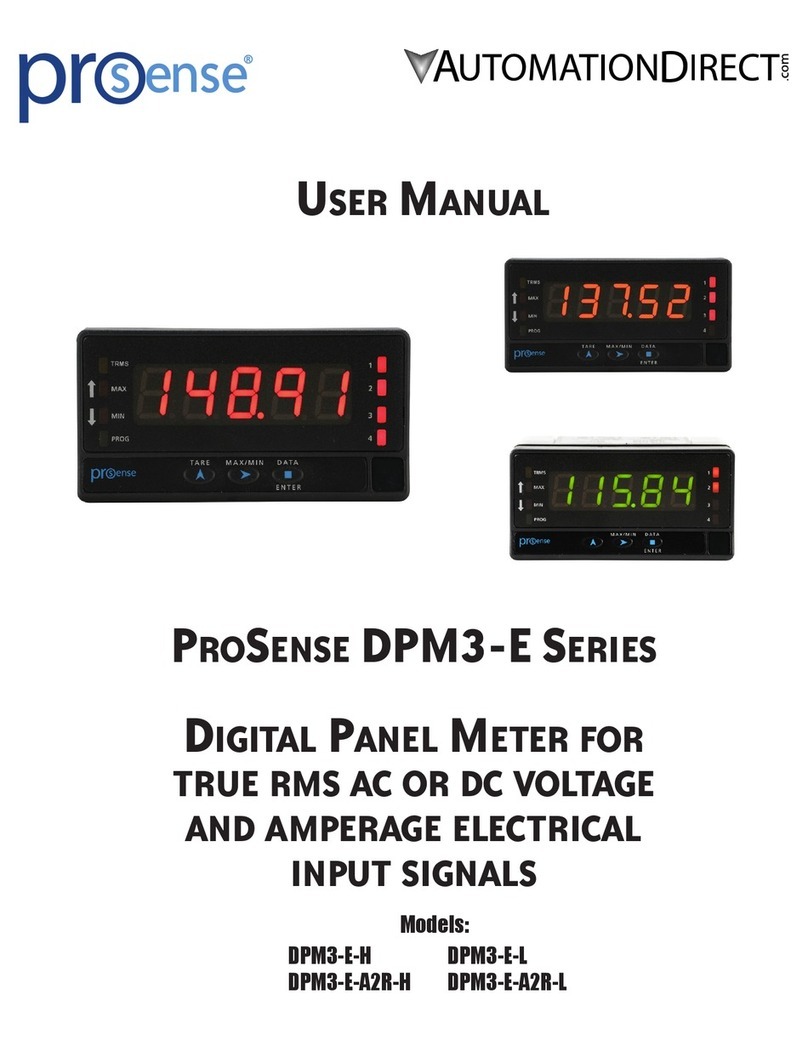

AutomationDirect ProSense DPM3-E Series User manual

AutomationDirect

AutomationDirect prosense TTD-20-N40160F-H User manual