BARTON®NUCLEAR

MODELS 351/352/353

LIQUID LEVEL SYSTEMS

Installation Manual

Part No. 9A-C10521, Rev. 03

November 2015

Contents

Safety............................................................................................................... 2

Section 1— Introduction................................................................................ 3

General ......................................................................................................... 3

Product Description....................................................................................... 4

Model 351 Liquid Level System ................................................................ 4

Model 352 Liquid Level System ................................................................ 4

Model 351/352 System Sensors ............................................................... 4

Model 353 Liquid Level System ................................................................ 5

Sensor Housings and Capillary Tubing......................................................... 5

Specications................................................................................................ 6

Section 2—Theory of Operation.................................................................... 7

General ......................................................................................................... 7

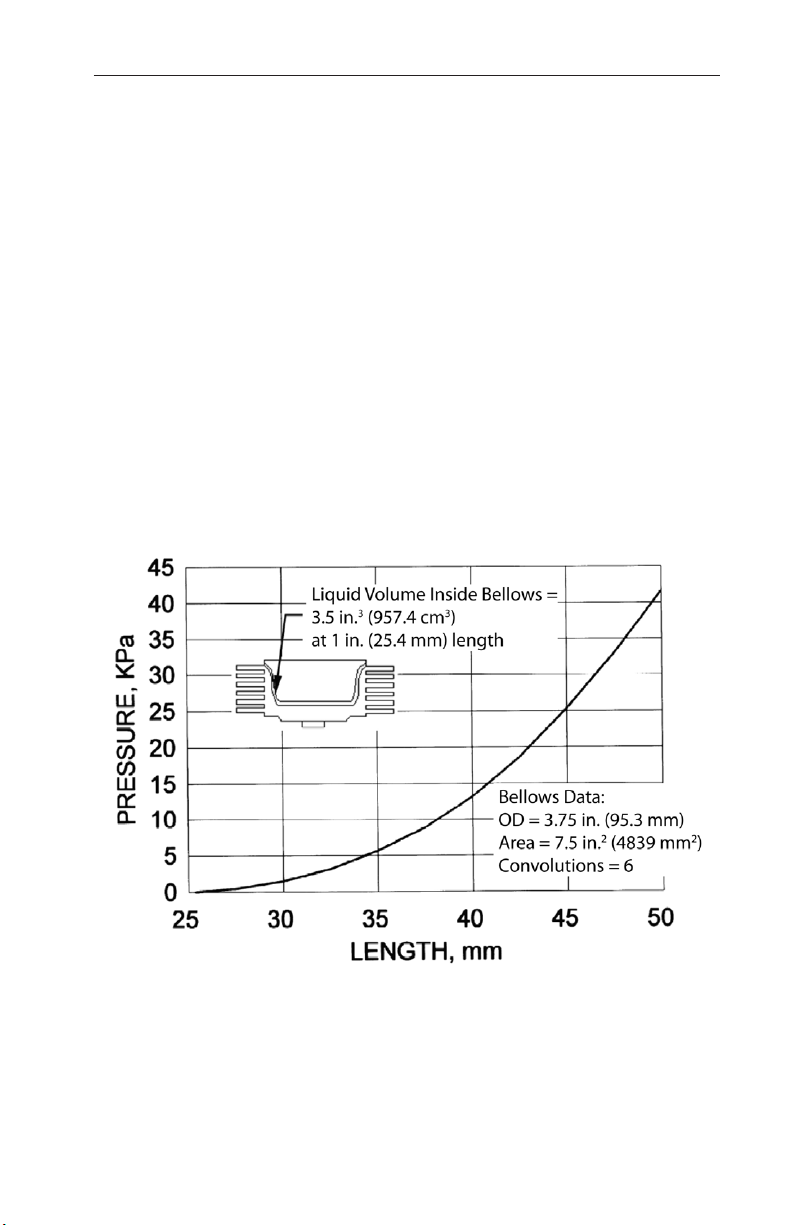

Model 353 Sensor ..................................................................................... 7

Section 3—Installation................................................................................... 9

Unpacking..................................................................................................... 9

Model 353 Sensor Assembly..................................................................... 9

Mounting ....................................................................................................... 9

Piping and Installation................................................................................... 9

Section 4—Operation, Maintenance, and Calibration............................... 13

Startup ........................................................................................................ 13

General Field and Periodic Maintenance.................................................... 13

Model 351 Sensor Inspection and Cleaning............................................ 13

Model 353 Sensor Inspection and Cleaning ........................................... 13

Model 353 Sensor Bellows Removal/Replacement.................................... 14

Calibration................................................................................................... 16

Troubleshooting .......................................................................................... 16

Section 5—Parts List.................................................................................... 17

General ....................................................................................................... 17

Section 6—Dimensional Drawings ............................................................. 27

General ....................................................................................................... 27

Product Warranty ........................................................................................ 33

Product Brand............................................................................................. 33