Advanced Type 7 inch Color Logic Panel

V-27

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

Drawing function

Function Description

Figure Line/Multi line/Rectangle/Round rectangle/Polygon/Circle/Fan/Chord/Arc/

Rectangle scale/Circle scale/Semicircle scale/Image/Text

Object

Lamp Displaying the value of the designated device in bit/word/multi lamp

Switch Switching the status of the designated device or object with bit/word/change screen/special/multi switch

Numeric input/display Displaying the value of the designated device/Inputting the value to the designated device in number (DEC,

HEX, OCT, BIN, REAL)

Text input/display Displaying the value of the designated device/Inputting the value to the designated device in text

(ASCII/Unicode)

Call window Calling a window screen according to the conditions on the value of the designated device

Message Displaying a message according to the conditions on the value of the designated device

Graph Displaying the value of the designated device in bar/pie/panel meter/statistic/RealTime trend/Logging trend/

RealTime distribution/Logging distribution graph

Clock Displaying time or date of the time

Recipe Editor Editing recipe (project)

Logging table Displaying the logging data (project) in a table

System logging table Displaying the system logging data (project) in a table

Alarm explorer Displaying the alarm group of alarm history (project) in a table

Alarm list Displaying the data of alarm history (project) in a table.

Data list viewer/editor Displaying/Editing the value of consecutive word device in a table

Option list Displaying the data of the designated device/Inputting data to the designated device in a combo box

Move coord. Displaying the object/Moving coordinate of the object according to the value of the

designated device

Project

Link device Reading/Writing the data between LP and controller (PLC) as long as setting according to the status of bit/

cycle condition

Flow alarm Displaying alarm in the flowing text at the set position, when meeting the alarming condition

Alarm history Saving data of alarming time, device, and information, when the value of the designated alarm-observing

device meets the set condition

Scheduler Executing a function (bit on/off/reversal, work value changing, script) according to the set condition (device/

cycle)

Recipe Reading the value of the multiple devices/Writing the value to the multiple devices at once

Logging Saving the value of the designated device, when meeting the condition (device/cycle)

System Logging Saving system operation information of LP in a log file

Script Writing Lua script by user

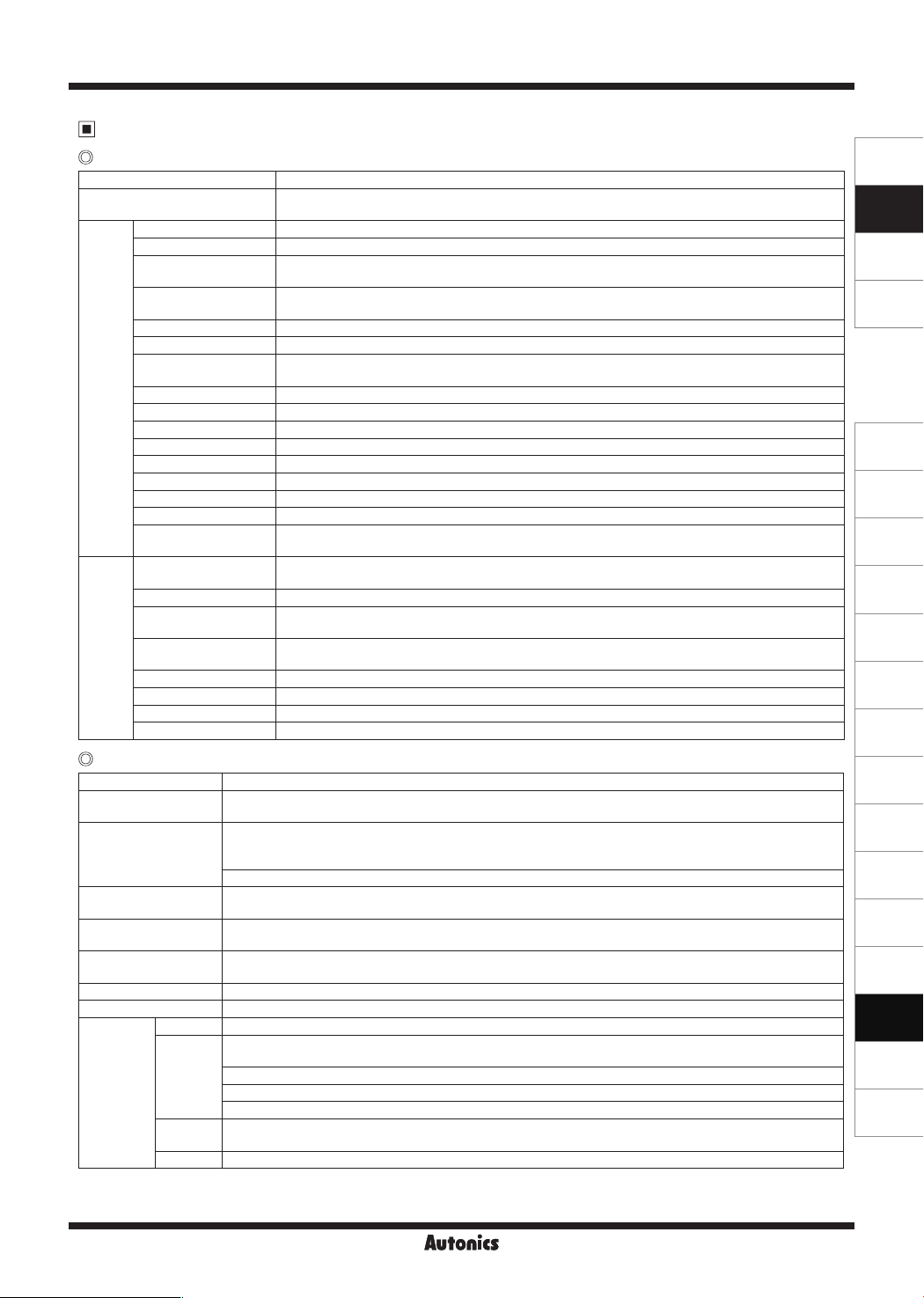

Logic function

Project Creating/Managing individual or multiple project. changing PLC type, printing, print setting

Edit Managing ladder/mnemonic editor, inserting/deleting line, managing rung, searching rung comment, search,

replace, nd step

Tool

Ladder tool: arrow, delete, vertical line, horizontal line, normally open contact, normally closed contact, rising input

contact, falling input contact, output instruction, rising output contact, falling output contact, set, reset, application

instruction, not instruction, register user defined function, user defined function

Program optimization, program checking, program checking options

View Ladder/Mnemonic, device/variable name, device name & comment, decimal/hexadecimal view, signed/unsigned

view, device/UW view, used devices, zoom in/out, font settings, color settings, toolbar

Online Connecting, disconnecting, download, upload, change mode, start monitoring, stop monitoring, read information,

change password, verify, change present value, system device, delete, firmware download, communication options

Debug Run, stop run, trace, insert/remove break point, stop debugging, debug-step, debug-line, debug-scan,

debug-1 scan, step in, step out, debug-bit, debug-word, forced I/O settings

window Cascade, horizontal tile, vertical tile, arrange icon, external program connection

Help Program information

Workspace

Program Ladder/Mnemonic program editor

Parameter

Common: output while debugging, operating condition for extended module, device latch range settings, default

lter value, time driven operation, time interrupt, timer range settings

Extension: input lter, external interrupt

Motion: common setting, operation setting, pattern setting

High speed counter

Variable/

Comment Managing and setting Variable/Comment by bit/word device

Monitoring Monitoring and registering device to monitor by bit/word device

Function