Instructions, AutroFlame X33AF, 116-P-X33AF/IGB, rev. E, 2013-08-13, P/N 95-8625-17.1, Rev: 2/13

Autronica Fire and Security AS

Page 4

GENERAL APPLICATION

INFORMATION

RESPONSE CHARACTERISTICS

Response is dependent on the detector's sensitivity

setting, distance, type of fuel, temperature of the fuel, and

time required for the re to come to equilibrium. As with

all re tests, results must be interpreted according to an

individual application.

See Appendix A for third-party approved re test results.

Additional re test results are available from Autronica.

IMPORTANT APPLICATION CONSIDERATIONS

In applying any type of sensing device as a re detector,

it is important to know of any conditions that can prevent

the device from responding to re, and also to know

what other sources besides re can cause the device to

respond.

Welding

Arc welding should not be performed within 40 feet

(12.2 m) of the detector congured to very high sensitivity,

within 10 feet (3.0 m) at medium sensitivity, within 5

feet (1.5 m) at T-Low sensitivity, or within 5 feet (1.5 m)

at Low sensitivity. It is recommended that the system be

bypassed during welding operations in situations where

the possibility of a false alarm cannot be tolerated. Gas

welding mandates system bypass, since the gas torch is

an actual re. Arc welding rods can contain organic binder

materials in the ux that burn during the welding operation

and are detectable by the X33AF. Welding rods with clay

binders do not burn and will not be detected by the X33AF.

However, system bypass is always recommended, since

the material being welded may be contaminated with

organic substances (paint, oil, etc.) that will burn and

possibly trigger the X33AF.

Articial Lighting

The X33AF should not be located within 3 feet (0.9 m) of

articial lights. Excess heating of the detector could occur

due to heat radiating from the lights.

EMI/RFI Interference

The X33AF is resistant to interference by EMI and RFI,

and is EMC Directive compliant. It will not respond to a 5

watt walkie-talkie at distances greater than 1 foot. Do not

operate a walkie-talkie within 1 foot of the X33AF.

Non-Carbon Fires

The X33AF is a multiple spectrum IR device with detection

limited to carbonaceous fuels. It should not be used to

detect res from fuels that do not contain carbon, such as

hydrogen, sulfur, and burning metals.

IMPORTANT SAFETY NOTES

WARNING

Do not open the detector assembly in a hazardous

area when power is applied. The detector contains

limited serviceable components and should never

be opened. Doing so could disturb critical optical

alignment and calibration parameters, possibly

causing serious damage.

CAUTION

The wiring procedures in this manual are intended

to ensure proper functioning of the device under

normal conditions. However, because of the

many variations in wiring codes and regulations,

total compliance to these ordinances cannot be

guaranteed. Be certain that all wiring complies

with the NEC as well as all local ordinances. If

in doubt, consult the authority having jurisdiction

before wiring the system. Installation must be

done by a properly trained person.

CAUTION

To prevent unwanted actuation or alarm,

extinguishing devices must be disabled prior to

performing system tests or maintenance.

CAUTION

The multispectrum IR ame detectors are to be

installed in places where the risk of mechanical

damages is low.

ATTENTION

Remove the protective cap from the front of the

detector before activating the system.

ATTENTION

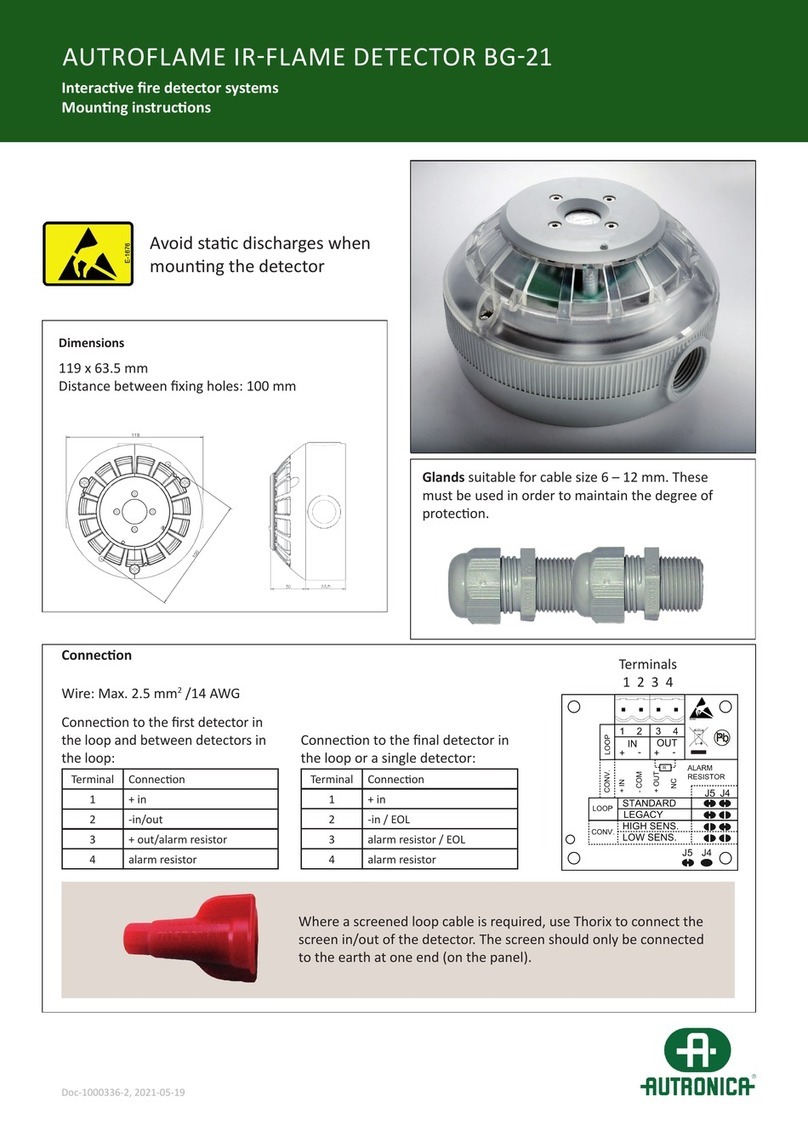

Observe precautions for handling electrostatic

sensitive devices.