Instructions, AutroFlame X33AFPL, 116-P-X33AFPL/IGB, rev. A, 2016-11-04

P/N 95-8750, v2.4, rev. 1/16

Autronica Fire and Security AS

DATA LOGGING

Data logging capability is also provided. Status conditions

such as normal, power down, general and

oi

faults, pre-

alarm, re alarm, time and temperature are recorded.

Each event is time and date stamped, along with the

temperature and input voltage. Event data is stored in

non-volatile memory when the event becomes active, and

again when the status changes. Data from the log can

only be extracted at the factory.

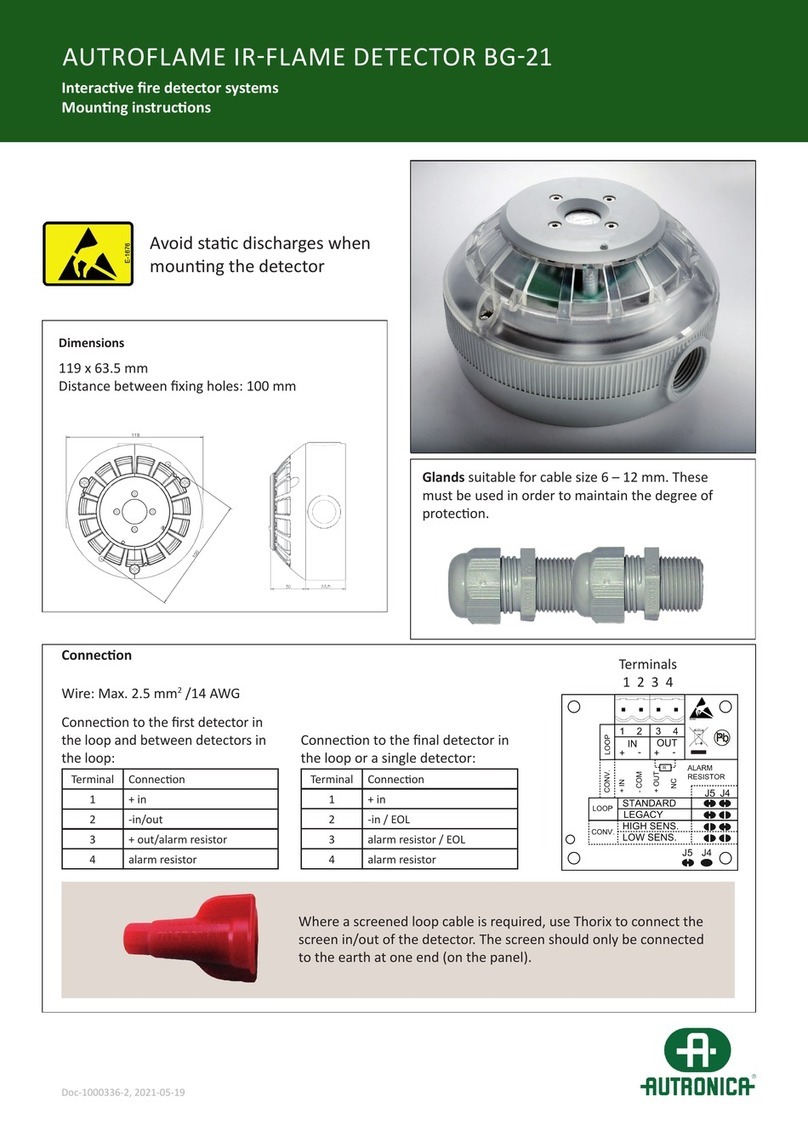

INTEGRAL WIRING COMPARTMENT

All external wiring to the device is connected within the

integral junction box. The detector is furnished with four

conduit entries, with M25 threads.

DETECTOR SENSITIVITY LEVELS

There are four factory congured sensitivity levels

available for the X33AF PL Flame Detector:

Very High, Medium, Low and T-Low.

The following criteria should be considered when

choosing a sensitivity level for the intended application:

• Detector placement

• Speed of response based on fuel type and re size

(see Appendix A for response times)

• Distance between the hazard and the ame

detector

Additional information on X33AF PL Flame Detector

performance results and sensitivities can be found in

Appendix A, the FM Approval and Performance Report.

Consult the factory with any questions on how to choose

the optimum sensitivity level for the intended application.

GENERAL APPLICATION

INFORMATION

RESPONSE CHARACTERISTICS

Response is dependent on the detector's sensitivity

setting, distance, type of fuel, temperature of the fuel, and

time required for the re to come to equilibrium. As with

all re tests, results must be interpreted according to an

individual application.

See Appendix A for third-party approved re test results.

Additional re test results are available from Autronica.

IMPORTANT APPLICATION CONSIDERATIONS

In applying any type of sensing device as a re detector,

it is important to know of any conditions that can prevent

the device from responding to re, and also to know

what other sources besides re can cause the device to

respond.

Welding

It is recommended that the system be bypassed

during welding operations in situations where the

possibility of a false alarm cannot be tolerated. Gas

welding mandates system bypass, since the gas torch

is an actual re. Arc welding rods can contain organic

binder materials in the ux that burn during the welding

operation and are detectable by the X33AF PL. Welding

rods with clay binders do not burn and will not be detected

by the X33AF PL. However, system bypass is always

recommended, since the material being welded may be

contaminated with organic substances (paint, oil, etc.)

that will burn and possibly cause the X33AF PL to alarm.

Due to the possibility of an alarm condition, arc welding

should not be performed within 40 feet (12.2 m) of the

detector configured to very high sensitivity, within 10

feet (3.0 m) at medium sensitivity, within 5 feet (1.5 m)

at T-Low sensitivity, or at Low sensitivity.

Articial Lighting

The X33AF PL should not be located within 3 feet (0.9 m)

of articial lights. Excess heating of the detector could

occur due to heat radiating from the lights.

EMI/RFI Interference

The X33AF PL is resistant to interference by EMI and RFI,

and is EMC Directive compliant. It will not respond to a

5 watt walkie-talkie at distances greater than 1 foot. Do

not operate a walkie-talkie within 1 foot of the X33AF PL.

Non-Carbon Fires

The X33AF PL is a multiple spectrum IR device with

detection limited to carbonaceous fuels. It should not be

used to detect res from fuels that do not contain carbon,