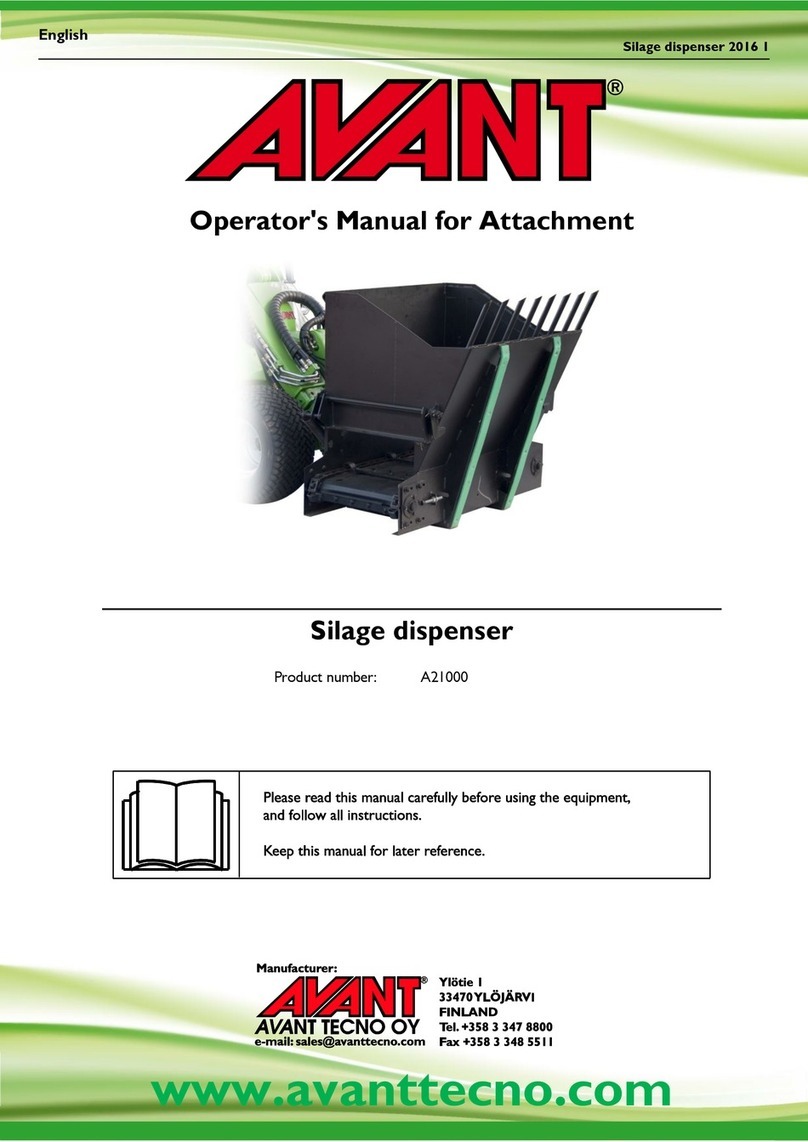

Silage dispenser 2020 1

CONTENTS

1. FOREWORD ........................................................................................................................................ 4

Warning symbols used in this manual ...................................................................................................................................5

2. DESIGNED PURPOSE OF USE.......................................................................................................... 6

3. SAFETY INSTRUCTIONS FOR USING THE ATTACHMENT...................................................... 7

3.1 Personal protective equipment...............................................................................................................................10

3.2 Safe shutdown procedure ........................................................................................................................................10

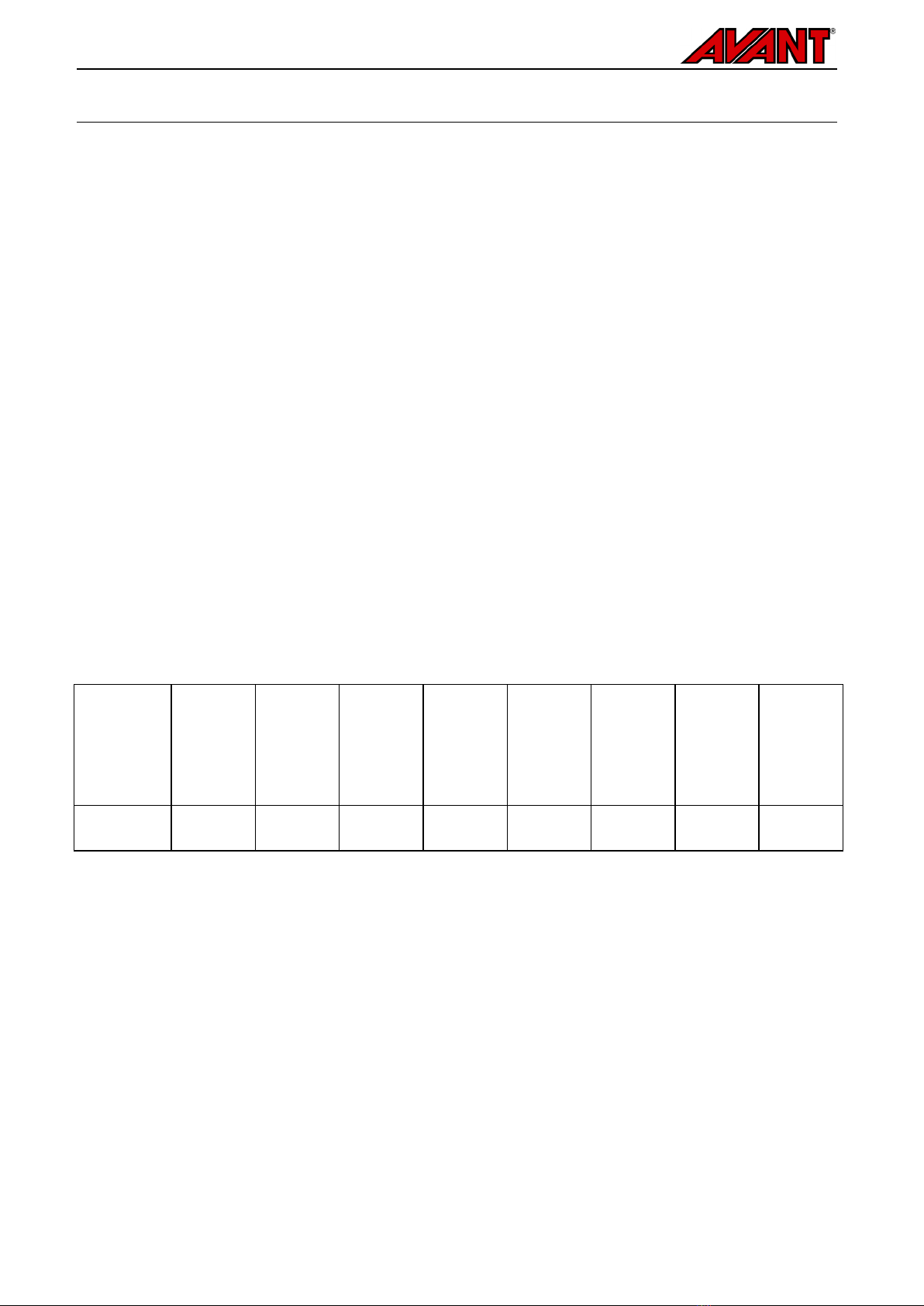

4. TECHNICAL SPECIFICATIONS ....................................................................................................... 11

4.1 Safety labels and main components of the attachment ....................................................................................11

5. ASSEMBLING THE ATTACHMENT................................................................................................. 13

5.1 Connecting and disconnecting hydraulic hoses ..................................................................................................14

5.2 Electric connection ....................................................................................................................................................16

5.2.1 To connect the electric harness of the attachment to the loader........................................................16

6. OPERATING THE ATTACHMENT .................................................................................................. 18

6.1 Checks before use .....................................................................................................................................................19

6.2 Operator qualification...............................................................................................................................................20

6.3 Filling the silage dispenser ........................................................................................................................................20

6.3.1 Filling the silage dispenser from silo or from a silage mixer...................................................................20

6.3.2 Filling the bucket ................................................................................................................................................22

6.4 Operating the Silage dispenser ...............................................................................................................................23

6.5 Adjusting dispensing rate..........................................................................................................................................24

6.6 Hydraulic side hatch operation (Optional extra)...............................................................................................25

6.6.1 Safety instructions for hydraulic assemblies................................................................................................25

6.6.2 Tightening hydraulic fittings.............................................................................................................................26

6.6.3 Installation............................................................................................................................................................27

6.6.4 Using the hydraulic side hatches....................................................................................................................28

6.7 Transport position .....................................................................................................................................................29

6.8 Working on uneven ground ....................................................................................................................................29

6.9 Operation with a tilt adapter ..................................................................................................................................29

6.10 Storing the attachment .............................................................................................................................................29

7. MAINTENANCE AND SERVICE ....................................................................................................... 31

7.1 Inspection of hydraulic components .....................................................................................................................31

7.2 Cleaning the attachment...........................................................................................................................................32

7.3 Inspection of metal structures................................................................................................................................32

7.3.1 Lip plate................................................................................................................................................................32

7.4 Lubrication ...................................................................................................................................................................32

7.5 Adjusting conveyor ....................................................................................................................................................33

8. WARRANTY TERMS .......................................................................................................................... 34