Avery Dennison Monarch 9860 User manual

Other Avery Dennison Label Maker manuals

Avery Dennison

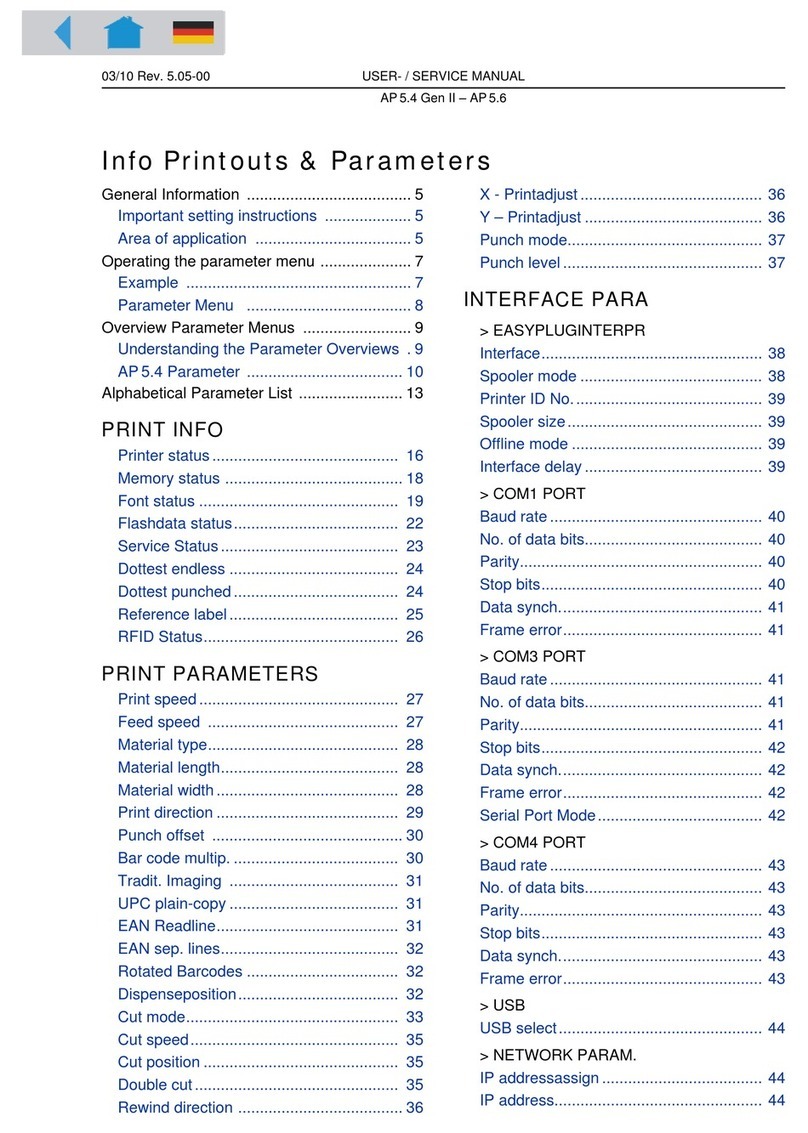

Avery Dennison AP5.4 User manual

Avery Dennison

Avery Dennison S 105 User manual

Avery Dennison

Avery Dennison TCS Guide

Avery Dennison

Avery Dennison ALS 221 User manual

Avery Dennison

Avery Dennison TTX 450 Troubleshooting guide

Avery Dennison

Avery Dennison ALS 421 User manual

Avery Dennison

Avery Dennison ALS 204 User manual

Avery Dennison

Avery Dennison FRESHMARX 9415 User manual

Avery Dennison

Avery Dennison Monarch 1115 User manual

Avery Dennison

Avery Dennison ALS 380 User manual

Avery Dennison

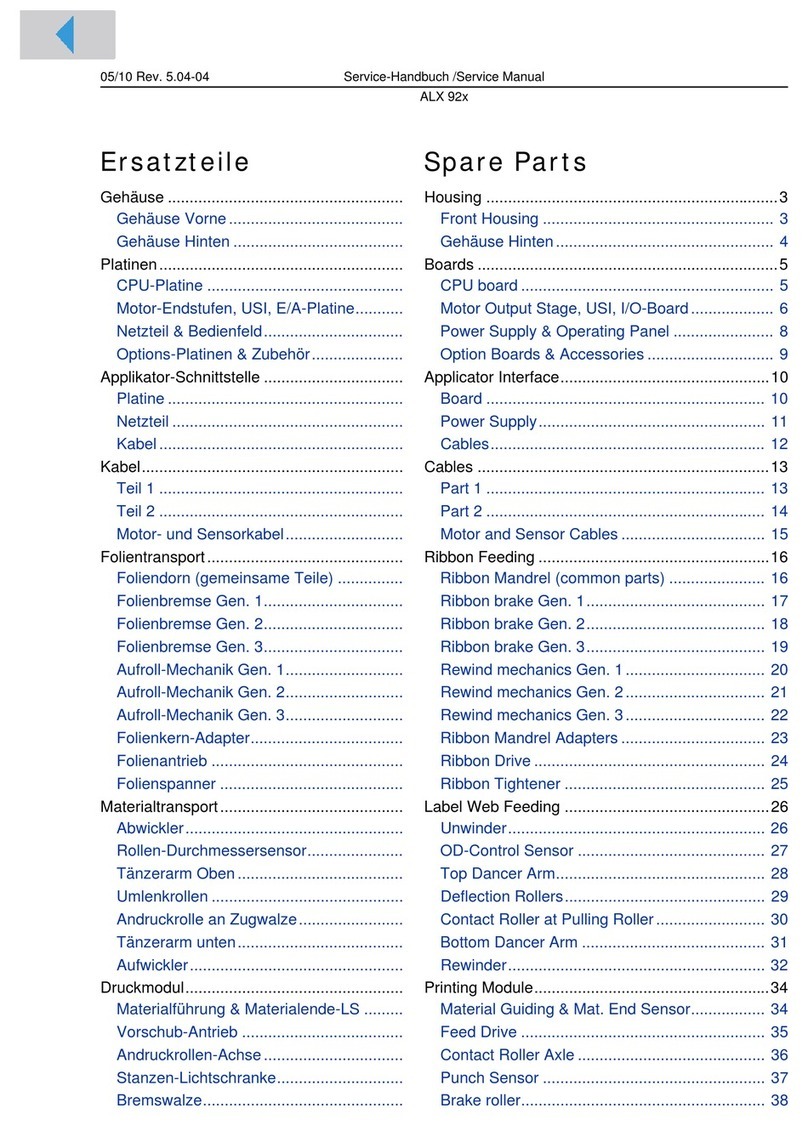

Avery Dennison ALX 92x User manual

Avery Dennison

Avery Dennison 64-Series User manual

Avery Dennison

Avery Dennison AP3.4 Troubleshooting guide

Avery Dennison

Avery Dennison SNAP 500 User manual

Avery Dennison

Avery Dennison AP3.4 User manual

Avery Dennison

Avery Dennison Labelers 1103-1110 User manual

Avery Dennison

Avery Dennison AP5.4 Troubleshooting guide

Avery Dennison

Avery Dennison AP5.4 Gen II Troubleshooting guide

Avery Dennison

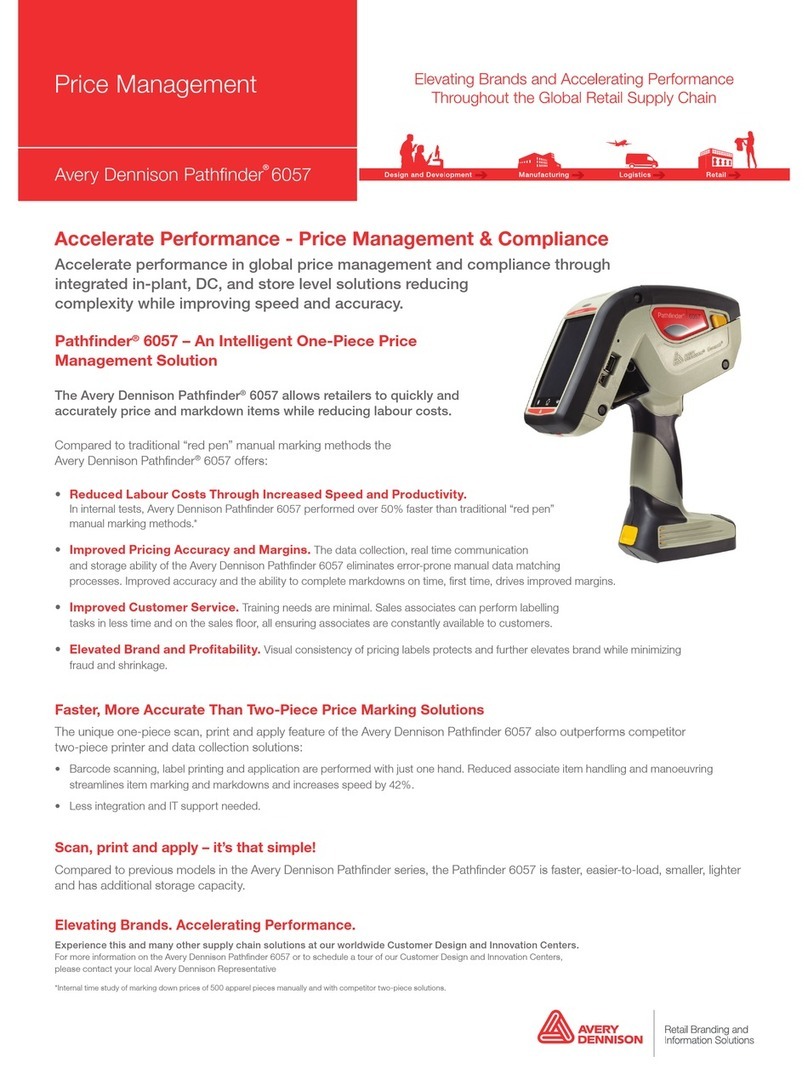

Avery Dennison Pathfinder 6057 Instruction Manual

Avery Dennison

Avery Dennison Monarch Freshmarx 9417+ Service manual