VAS 581 009 Start-Up Guide V02 06/2021 All rights reserved.

Start-Up Guide EN

Mandatory signs

Refrigerating agent cylinder

Secure CO2(R744)

Wear respiratory

protection

SAFETY INSTRUCTIONS FOR CARBON DIOXIDE CO2(R744)

Always observe the manufacturer's safety data sheet.

Contact with the product can cause cold burns or frostbite.

Gases/vapors are heavier than air. High concentration due to accumulation in closed rooms, work pits, cellars, etc. can

cause asphyxiation, among other things. Symptoms: Loss of motor ability and consciousness. Affected persons do not

realize that they are suffocating.

Do not allow carbon monoxide to enter sewage systems, pits or similar enclosures where gas accumulation may be

dangerous.

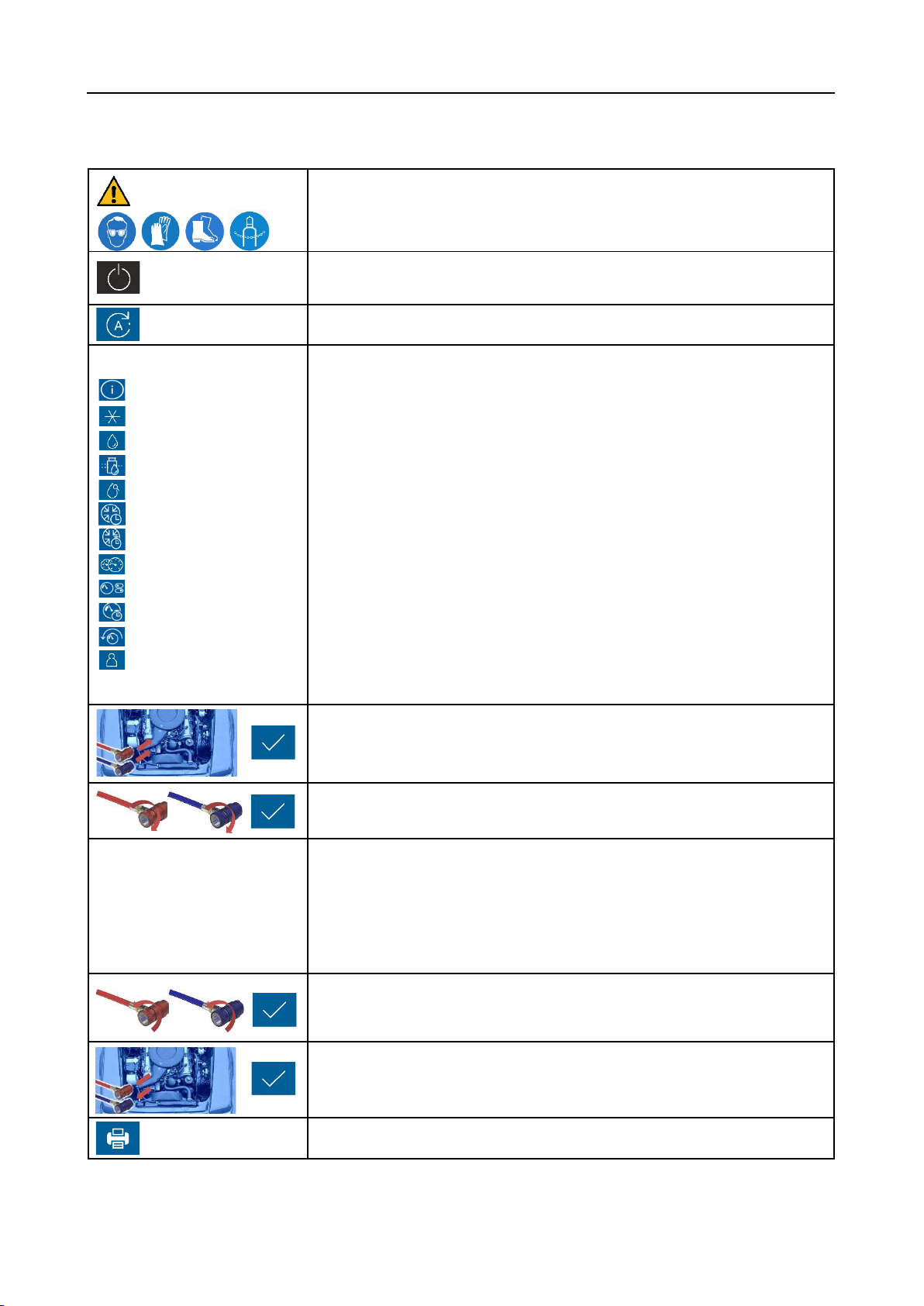

Precautions and behavior rules

Storage: Store container in a well-ventilated place at a temperature below 50 °C. Protect container against impacts

and falls (secure with chain).

Handling: Avoid contact with eyes and skin. Do not inhale the gas. Ensure that no water enters the gas

cylinder/container.

Prevent the gas from flowing back into the gas tank. Only use equipment that is suitable for this product and the

intended pressure and temperature. Check fittings, connections and lines for leaks. Eating, drinking and storing food in

the working area are prohibited.

Respiratory protection: Self-contained breathing apparatus. Eye protection: Tightly fitting protective goggles.

Hand protection: Protective gloves (material: leather). Body protection: Protective clothing.

Behavior in the event of danger

After a gas leak: Keep unprotected persons away. Ventilate rooms well. Wear protective gear and self-contained

breathing apparatus. Close valves / stop gas leak. Avoid entry into cellars, pits and similar enclosures (danger of

suffocation).

In case of fire: Wear protective gear and self-contained breathing apparatus. Stop gas leak if possible. Cool cylinders

with a water jet from a secure position and remove them from the fire zone if possible to prevent explosion. The product

itself is non-flammable. Extinguishing agents: All known extinguishing agents can be used. Escape routes: Escape

routes must be known to staff. Accident phone: The accident phone must be known to staff.

First aid Please observe the instructions for use and safety of your refrigerant supplier.

SAFETY INSTRUCTIONS FOR NITROGEN N2

Always observe the manufacturer's safety data sheet.

Further safety information can be found in the operating manual