1

AWA Heathkit HP-23 Power Supply PCB Upgrade Instructions V1.4

Thank you for purchasing the AWA Heathkit HP-23 Power Supply Upgrade Board.

This board will allow easy upgrading of all diodes, capacitors, and resistors for extended

life of your HP-23 power supply.

Note: This printed circuit board upgrade is intended only for persons experienced in

working with high voltage circuitry. The completed upgrade and associated components

produce potentially dangerous voltages. Always install the Heathkit HP-23 perforated

metal cover when operating the HP-23.

There were at least five different versions of the HP-23 supply starting with the

HP-23 then the A, B, and C models and ending with the PS-23. They all have the same

4 basic outputs: High Voltage, HV, at 700VDC @250ma, B+ at 300VDC @150ma or B+

at 250VDC @100ma, Bias at -100VDC @20ma, filament at 12.6VAC @5.5A. Earlier

versions had a switch for Hi or Lo B+, adjustable and fixed Bias voltage, and could

supply 6.3VAC and 12.6VAC for filaments, and were 120VAC input only. Later versions

eliminated the switch for Hi or Lo B+ and were hard wired, the Bias voltage was fixed,

and the filament voltage was only 12.6VAC. The AC input could be wired for 120 or

240VAC.

The AWA PCB should be usable in all these versions.

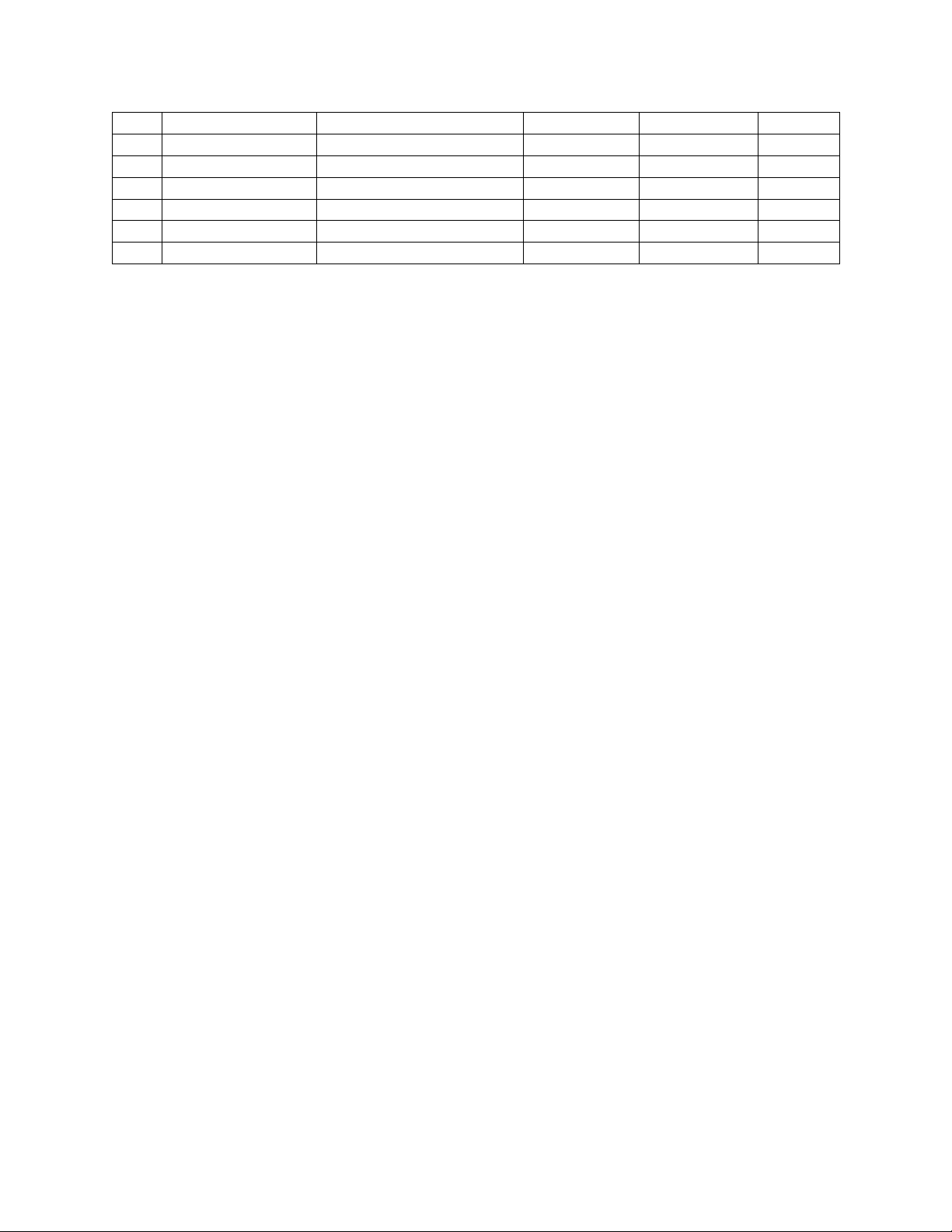

The AWA Upgrade PCB uses diodes in the HV section (D1,D2,D3,D4) upgraded to

1000PIV and 1A (1N4007) or optionally, 1000PIV and 3A(1N5308). Diodes D5,D6,D7

are 1N4007s. The HV and B+ caps C1-C4 were upgraded to 150uF at 500VDC. B+

cap C5, is upgraded to 47uF at 450VDC. Bias caps, C6 and C7 are upgraded to 47uF

at 200VDC. The PCB is designed to use modern, snap-in caps with 10mm lead

spacing. Leaded (or taller snap-in caps) caps can be used but must be less than

approx. 1.7” in height to prevent hitting the filter choke with the PCB mounting

suggested. The bleeder resistors specified are TE Connectivity ROX series metal oxide

with a flameproof rating. These have a 5 watt rating and are a little smaller than a 2

watt carbon comp resistor. R8, is a 0.33Ω, 3W additional resistor recommended in a

HP-23 upgrade article by Mike Bryce, WB8VGE in October, 2003 QST. This resistor in

the B+ output is supposed to limit current for a short period of time if the B+ is shorted.

This can be jumpered out, if desired. Another option feature to the original circuit is to

add a HV fuse (F2). This is a 0.25” x 1.25” (3AG) size fast blow fuse rated 500ma at

1000V. This is a SIBA fuse part# 7017240 widely available as it is used as a multimeter

protection fuse. This can be jumpered out, if desired, also.

The PCB board is mounted vertically using the old HV filter cap mounting holes located

near the outside edges of the chassis closest to the transformer. The board is mounted

using 2 Keystone #614 Angle Brackets and #6 hardware. The 2 screws in the vertical

(threaded) leg of the angle bracket can be removed to allow easy board removal for

repairs, etc. The board is 4.50” wide and 3.90” tall. Angle bracket mounting holes are

4.10” apart to match the old filter cap mounting hole centers.

Copyright Antique Wireless Association 2023 –www.antiquewireless.org