CONTENTS

ND Series Operating & Instruction Manual Page ii

GENERAL.................................................................................................................................................1

Construction features...........................................................................................................................1

Pump casing.....................................................................................................................................1

Shaft seal housing ............................................................................................................................1

Support ............................................................................................................................................1

Pump nameplate..............................................................................................................................1

Fields of applications............................................................................................................................2

Precautions during operation...............................................................................................................3

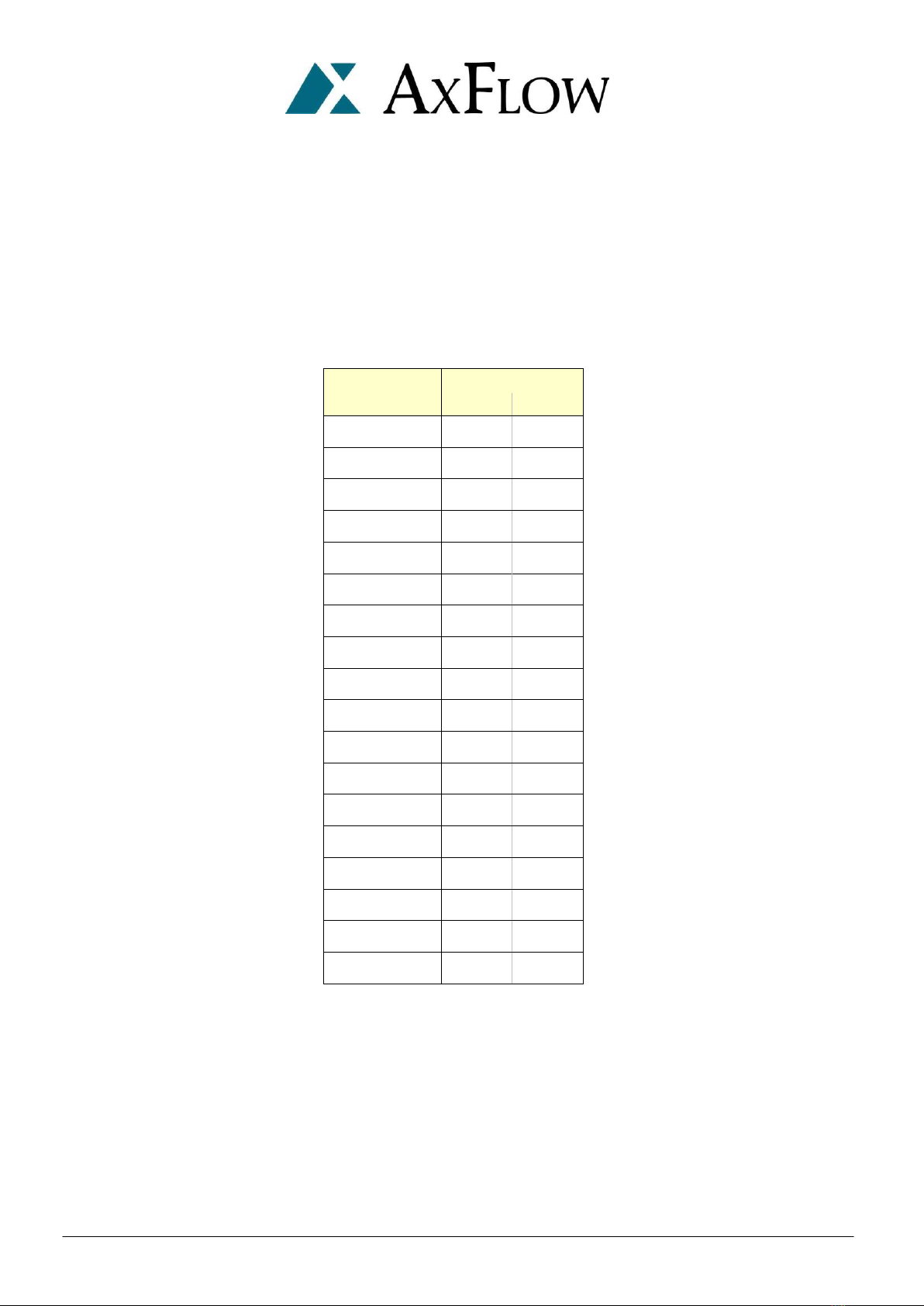

Noise levels ..........................................................................................................................................3

Operating limits ...................................................................................................................................5

Residual risks........................................................................................................................................5

In case of emergency............................................................................................................................6

Area of operation .................................................................................................................................6

Spare parts...........................................................................................................................................6

Transport .............................................................................................................................................7

Storage ................................................................................................................................................8

Storage for a period shorter than 3 months......................................................................................8

Storage for a period exceeding 3 months (but shorter than 12 months)...........................................8

Storage (after operation)..................................................................................................................8

Drivers..................................................................................................................................................9

INSTALLATION......................................................................................................................................10

Site installation ..................................................................................................................................10

Foundations .......................................................................................................................................10

Motor-pump units on baseplates....................................................................................................10

Pump and motor alignment ............................................................................................................... 11

Methods of checking alignment.........................................................................................................12

Straight edge..................................................................................................................................12

Dial gauge ("clocking") ................................................................................................................... 13

Optical methods............................................................................................................................. 13

Location and piping............................................................................................................................14

Admissible external forces and torques on pump flanges .................................................................. 17

Protecting the pump against dry running...........................................................................................18

Loss of liquid supply .......................................................................................................................18

Low inlet pressure ..........................................................................................................................18

`Dead-heading'...............................................................................................................................18

Electronic dry running protection.......................................................................................................18

Electrical connection..........................................................................................................................19

Connecting the electric motor........................................................................................................19

Oil lubricated......................................................................................................................................20

Bearings .........................................................................................................................................20

Oil type...........................................................................................................................................20

Direction of rotation...........................................................................................................................21