Page | 7

The user menu has the following options:

1) i (info) - This option allows you to display the software version and returns the information about

the set communication protocol. Exiting the info option is done automatically after displaying

the information.

2) P (proto) - This option allows you to select a signalling device communication protocol to work

with the given control modules uploaded to the device memory. You can change a protocol by

pressing the microbutton. Accepting the selected protocol is accomplished by long holding

down the microbutton (until the inscription "Ok" appears). Exiting the "proto" option comes

after 30 seconds of the user inactivity.

3) C (custom) - The "custom" option allows you to select a dedicated signalling device

communication protocol to work with the control modules of selected clients. The protocols have

special, custom settings needed for a given customer. Setting a protocol is done in the same way

as in the case of the "proto" option - accepting the selected protocol is accomplished by long

holding down the microbutton (until the inscription "Ok" appears), while exiting the "custom"

option comes automatically after 30 seconds of the user inactivity.

4) R (reset) - This option allows you to reset the default light signalling device protocol. In

addition, in the devices with the Ethernet interface, you can restore the default network layer

settings (IP address: 192.168.0.11, network mask: 255.255.255.0, and the communication port

for the control module). To restore the default settings you should, during the normal

operation of the device, press the microbutton and hold it down until the inscription "R"

appears. Hold the button down until the inscription "R" starts flashing and do not release it

until the information "default" is displayed. Releasing the button before the inscription

"default" appears will result in interrupting the process of restoring the default settings and

the display will continue working according to the previously accepted parameters.

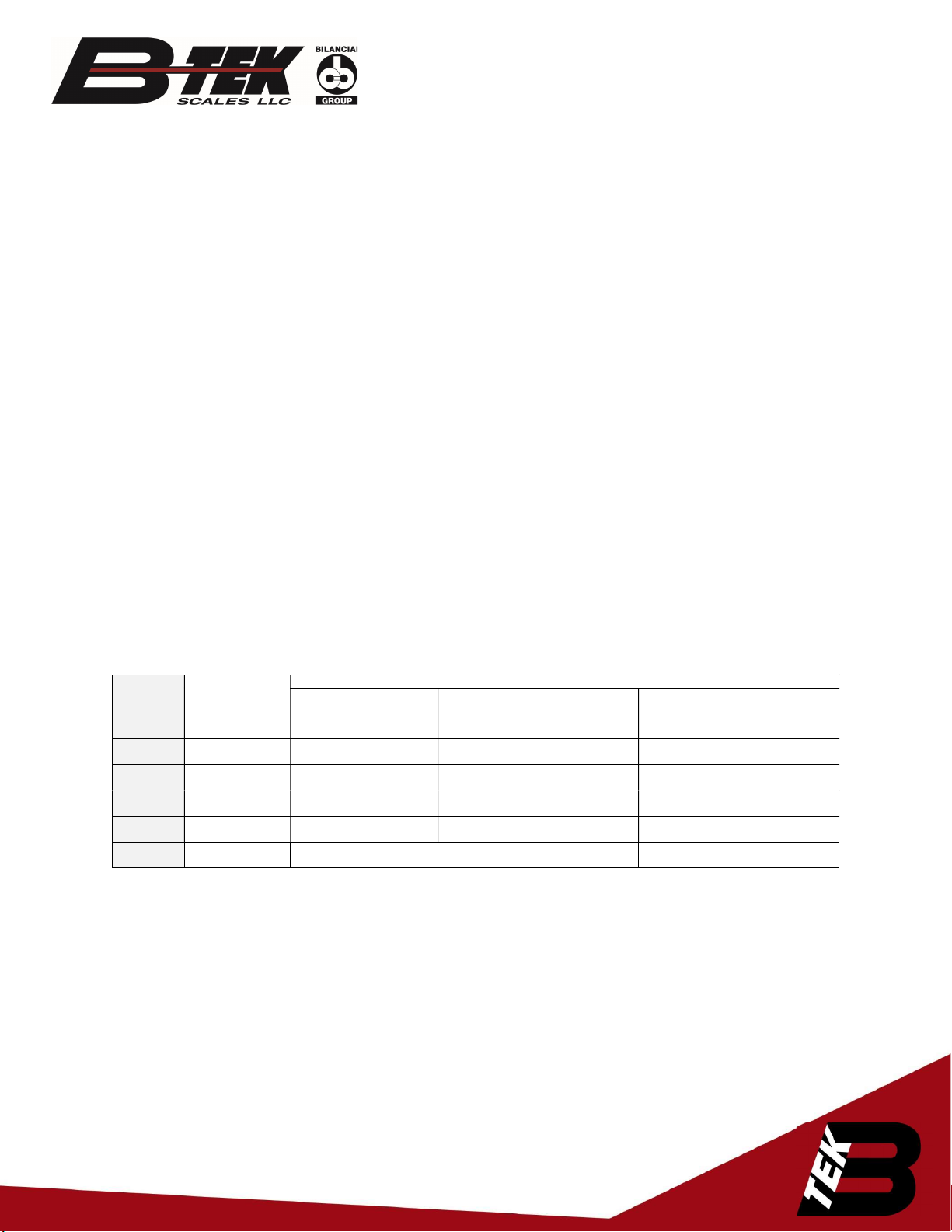

The list of the supported protocols.

Protocol

no. in the

menu

Protocol

The response to the

pressing button on the

operator panel

The response to not pressing the

button on the operator panel or the

lack of communication with the

The response to the long,

simultaneous holding of the red and

green button on the operator panel

1 Standard Turning on the red, green

By default, the red light comes on Turning off the signalling device

2 Standard Turning on the red, green

The last status is saved Turning on the red and green light

3 Standard Turning on the red, green

The operator panel cable connection

failure is signalled: „XX”

Turning off the signalling device

4 Standard Turning on the red, green

The cable connection failure is

Turning on the red light

5 Pfister DWT800 Turning on the red, green

The cable connection failure is

Turning off the signalling device