2

Contents

Contents.................................................................................................................................... 2

Important Information.............................................................................................................. 2

Pictograms................................................................................................................................ 3

Explanation of the pictograms on the wet concrete cutter / chaser........................................ 3

Explanation of the pictograms used in the text....................................................................... 3

For your Safety......................................................................................................................... 4

General safety instructions for power tools ................................................................................ 4

1) Safety at the place of work .............................................................................................. 4

2) Electrical safety ............................................................................................................... 4

3) Safety of people............................................................................................................... 5

4) Use and handling of the power tool ................................................................................. 5

5) Service............................................................................................................................. 6

Machine-Specific Safety Instructions ..................................................................................... 6

Operating personnel requirements .................................................................................. 6

Workplace safety ............................................................................................................. 6

Electrical safety................................................................................................................ 7

Safety of people ............................................................................................................... 8

Hazards when using and handling the power tool ........................................................... 9

Service / maintenance / repair ....................................................................................... 11

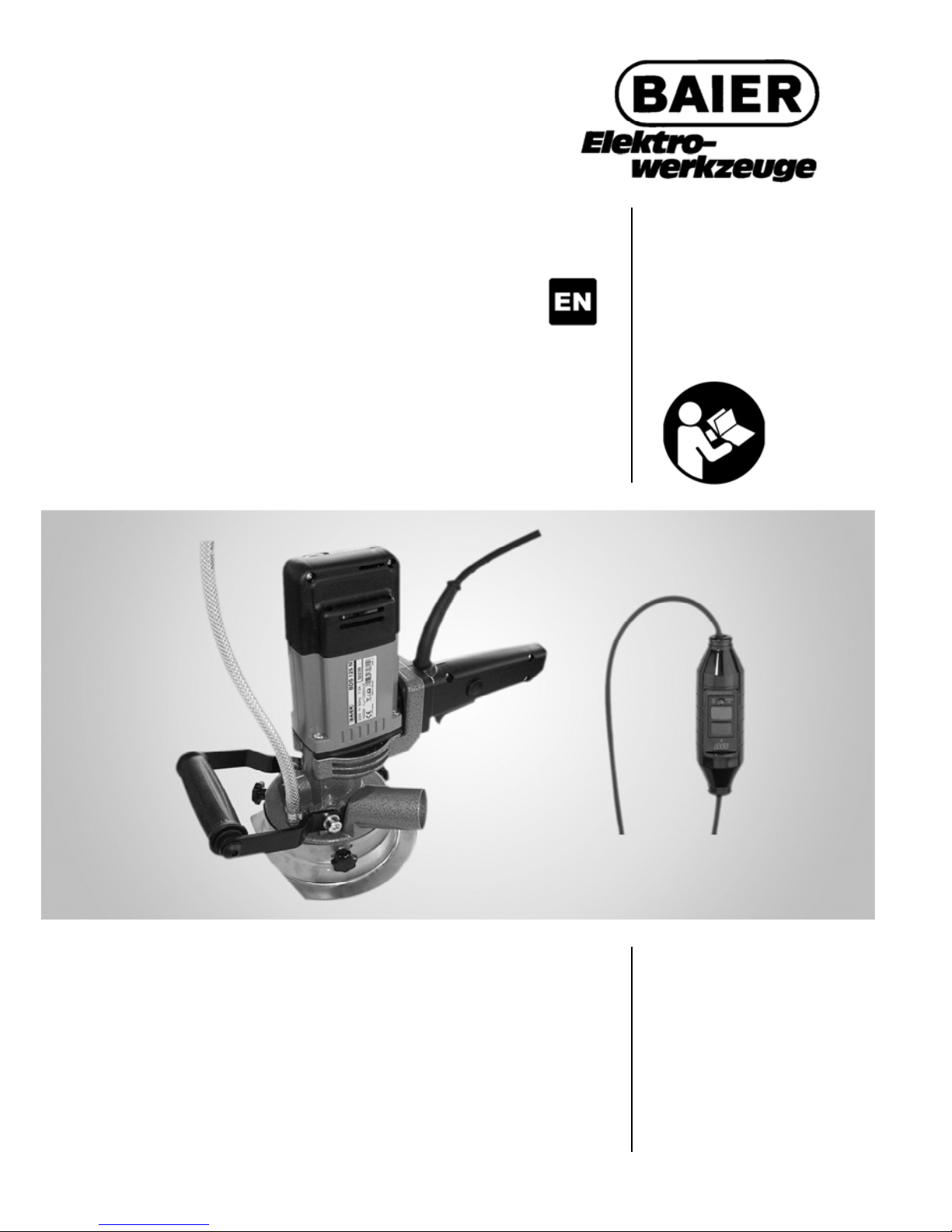

Technical Characteristics...................................................................................................... 12

Technical specifications ....................................................................................................... 12

Machine characteristics........................................................................................................ 12

Scope of Supply..................................................................................................................... 12

Intended Use........................................................................................................................... 12

Machine Parts and Controls.................................................................................................. 13

Tools and Accessories.......................................................................................................... 13

Before Starting Work ............................................................................................................. 14

Adjusting the front handle..................................................................................................... 15

Check personal protection switch......................................................................................... 15

Operation and Control........................................................................................................... 16

Fitting or changing grinding discs......................................................................................... 16

Adjusting the cutting depth ................................................................................................... 17

Connecting the dust and/or water extractor ......................................................................... 17

Adjust water supply .............................................................................................................. 18

Switching on the wet concrete cutter / chaser and cutting ................................................... 18

Finish cutting process........................................................................................................... 19

Cleaning.................................................................................................................................. 20

Maintenance............................................................................................................................ 20

Declaration of Conformity..................................................................................................... 20

Warranty.................................................................................................................................. 21

Important Information

Before starting any work with or on the machine, this instruction manual, the

safety instructions and the warnings must be read through carefully and ob-

served.

Always store this instruction manual together with the machine.