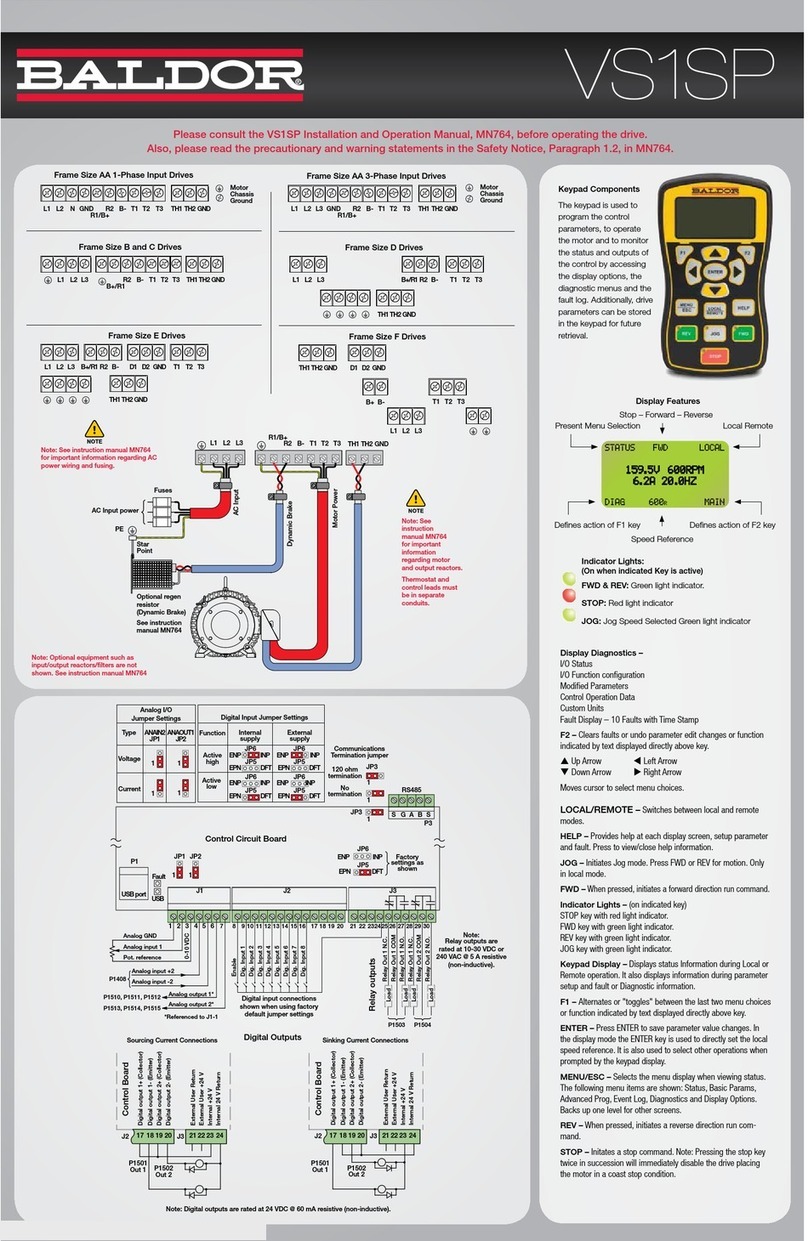

STATUS

BASIC PARAMS

ADVANCED PROG

EVENT LOG

DIAGNOSTICS

STATUS BACK

STATUS

BASIC PARAMS

ADVANCED PROG

EVENT LOG

DIAGNOSTICS

STATUS BACK

STATUS

BASIC PARAMS

ADVANCED PROG

EVENT LOG

DIAGNOSTICS

STATUS BACK

STATUS

BASIC PARAMS

ADVANCED PROG

EVENT LOG

DIAGNOSTICS

STATUS BACK

STATUS

BASIC PARAMS

ADVANCED PROG

EVENT LOG

DIAGNOSTICS

STATUS BACK

STATUS

BASIC PARAMS

ADVANCED PROG

EVENT LOG

DIAGNOSTICS

STATUS BACK

LEVEL 1 BLOCKS

LEVEL 2 BLOCKS

LEVEL 3 BLOCKS

MODIFIED PARAMS

LINEAR LIST

STATUS BACK

LEVEL 1 BLOCKS

LEVEL 2 BLOCKS

LEVEL 3 BLOCKS

MODIFIED PARAMS

LINEAR LIST

STATUS BACK

LEVEL 1 BLOCKS

LEVEL 2 BLOCKS

LEVEL 3 BLOCKS

MODIFIED PARAMS

LINEAR LIST

STATUS BACK

BASIC PARAMS BASIC PARAMS BASIC PARAMS

LEVEL 2 BLOCKS

LEVEL 2 BLOCKS LEVEL 2 BLOCKS

ADVANCED PROG

ADVANCED PROG ADVANCED PROG

Auto Tuning Procedures for Closed Vector, Open Vector and V/F Control

For Closed Vector Control Type: For Open Vector Control Type: For V/F Control Type:

1) Press MENU.

Scroll to BASIC PARAMS.

Press ENTER.

At this point the display

shows CONTROL TYPE

F1601, – the default value is

"Closed Vector" – press EN-

TER to change the setting to

Open Vector C1601, – press

ENTER.

2) Press the DOWN Arrow

key and enter values from the

motor nameplate for each of

the following "MOTOR DATA"

parameters. Press ENTER

to begin editing – after each

value is programmed, press

ENTER then DOWN arrow for

the next item.

• MOTOR RATED HP

• MOTOR RATED VOLT

• MOTOR RATED AMPS

• MOTOR MAG AMPS*

• MOTOR RATED SPD

• MOTOR RATED FREQ

*If this is not shown on the

motor nameplate, use the

formula:

MOTOR MAG AMPS = 0.4 X

MOTOR RATED AMPS.

3) CALC MOTOR MODEL –

press ENTER – select "Yes"

– press ENTER

4) After CALC MOTOR

MODEL is complete, Press

F2 to exit MOTOR DATA and

BASIC PARAMS to return to

the MENU.

5) ENABLE DRIVE, (close

J2-8 – J3-24 circuit).

6) Scroll to ADVANCED

PROG – press ENTER.

7) Scroll to LEVEL 2 BLOCKS

– press ENTER

8) Scroll to AUTO TUNE –

press ENTER.

9) Skip ANA OFFSET TRIM

– Scroll to ONE-STEP TUN-

ING – press ENTER – select

"Yes" – press ENTER. The

ONE-STEP TUNING will

take approx. 3-4 minutes to

complete.

10) After the static portion

of AUTO TUNE is complete,

the display will alternately

show STATIC TEST DONE

– ROTARY FOLLOW and

PRESS ENTER FOR FLUX

CUR TUNE. Select one of the

following:

a) if the motor is coupled

to the load, press F2 to exit

AUTO TUNING

b) If the motor is not coupled

to the load, press ENTER to

begin rotation tuning. The

rst test is "FOR FLUX CUR

TUNE" – press ENTER.

11) After "FLUX CUR TUNE"

TEST PASSED – press

ENTER for "MEASURE

Xm(ROT)"

12) After "MEASURE

Xm(ROT)" TEST PASSED –

press ENTER for "END OF

TEST".

13) PRESS F2 three times to

return to MENU – press F1 to

show STATUS display.

14) Couple motor to load and

run " SPEED LOOP TUNE"

to get a better response or

manually tune the speed

loop using Speed Prop Gain

(P1635), Speed Int Gain

(P1636) and Speed Diff Gain

(P1637)

OPEN VECTOR AUTO TUNE

COMPLETE

1) Press MENU.

Scroll to BASIC PARAMS.

Press ENTER.

At this point the display

shows CONTROL TYPE

F1601, – the default value is

"CLOSED VECTOR" – press

ENTER to change the setting

to V/F Control C1601, –

press ENTER.

2) Press the DOWN Arrow

key and enter values from the

motor nameplate for each of

the following "MOTOR DATA"

parameters. Press ENTER

to begin editing – after each

value is programmed, press

ENTER then DOWN arrow for

the next item.

• MOTOR RATED HP

• MOTOR RATED VOLT

• MOTOR RATED AMPS

• MOTOR MAG AMPS*

• MOTOR RATED SPD

• MOTOR RATED FREQ

*If this is not shown on the

motor nameplate, use the

formula:

MOTOR MAG AMPS = 0.4 X

MOTOR RATED AMPS.

3) CALC MOTOR MODEL –

press ENTER – select YES

– press ENTER

4) After CALC MOTOR

MODEL is complete, Press

F2 to exit MOTOR DATA and

BASIC PARAMS to return to

the MENU.

5) ENABLE DRIVE, (close

J2-8 – J3-24 circuit).

6) Scroll to ADVANCED

PROG – press ENTER.

7) Scroll to LEVEL 2 BLOCKS

– press ENTER

8) Scroll to AUTO TUNE –

press ENTER.

9) Skip ANA OFFSET

TRIM – Scroll to STATOR

R1 TUNE – press ENTER –

select "Yes" – Press ENTER.

After STATOR R1 TUNE is

complete – (TEST PASSED),

press ENTER to END (This is

a static tune, motor will not

rotate).

10) PRESS F2 three times to

return to MENU – press F1 to

show STATUS display.

V/F CONTROL AUTO TUNE

COMPLETE

1) Press MENU.

Scroll to BASIC PARAMS.

Press ENTER.

At this point the display shows

CONTROL TYPE F1601,– the

default value is "Closed Vector"

– press DOWN arrow to con-

tinue "Closed Vector" tuning.

2) Enter values from the mo-

tor nameplate for each of the

following "MOTOR DATA"

parameters. Press ENTER to

begin editing – after each value

is programmed, press ENTER

then DOWN arrow for the next

item.

• MOTOR RATED HP

• MOTOR RATED VOLT

• MOTOR RATED AMPS

• MOTOR MAG AMPS*

• MOTOR RATED SPD

• MOTOR RATED FREQ

*If this is not shown on the mo-

tor nameplate, use the formula:

MOTOR MAG AMPS = 0.4 X

MOTOR RATED AMPS.

3) FEEDBACK SOURCE –

(Standard VS1GV drives factory

setting is "Daughter FDBK") –

press DOWN arrow.

4) ENCODER COUNTS – Enter

the Pulse Per Revolution value,

PPR – press DOWN arrow.

5) Scroll to CALC MOTOR

MODEL – press ENTER – select

YES – press ENTER.

6) After CALC MOTOR MODEL

is complete, press F2 to exit

MOTOR DATA and BASIC

PARAMS to return to the menu.

7) ENABLE DRIVE, (Close J2-8

– J3-24 circuit).

8) Scroll to ADVANCED PROG

– press ENTER.

9) Scroll to LEVEL 2 BLOCKS –

press ENTER

10) Scroll to AUTO TUNE –

press ENTER

11) Skip ANA OFFSET TRIM –

Scroll to ONE-STEP TUNING

– press ENTER – select Yes –

press ENTER. The ONE-STEP

TUNING will take approx. 3-4

minutes to complete.

12) After the static portion of

AUTO TUNE is complete, the

display will alternately show

STATIC TEST DONE – ROTARY

FOLLOW and PRESS ENTER

FOR FEEDBACK ALIGN. Select

one of the following:

a) if the motor is coupled to the

load, press F2 to exit AUTO

TUNING

b) If the motor is not coupled to

the load, press ENTER to begin

rotation tuning. The rst test is

"FEEDBACK ALIGN" – press

ENTER.

13) After "FEEDBACK ALIGN"

TEST PASSED – press ENTER

for "FLUX CUR TUNE".

14) After "FLUX CUR TUNE"

TEST PASSED – press ENTER

for "MEASURE Xm(ROT)"

(Note: All procedures require that load be decoupled from motor shaft. See details below if this is not possible.

15) After "MEASURE Xm(ROT)" TEST PASSED –

press ENTER for "SPD LOOP TUNE".

16) After "SPD LOOP TUNE" TEST PASSED – press

ENTER for "END OF TEST".

17) Press F2 to return to the MENU – press F1 to

return to the STATUS display.

Optional Fine Tune (Steps 18 and 19)

18) Some applications perform better when the drive

is tuned with the load. For further tuning couple the

motor to the load.

19) Run the SPD LOOP TUNE to automatically tune

the speed loop, or adjust SPEED PROP GAIN, SPEED

INT GAIN, and SPEED DIFF GAIN to manually tune.

CLOSED VECTOR AUTO TUNE COMPLETE

BASIC MOTOR CONTROL

CONTROL TYPE

Closed Vector

STATUS F1601T1 BACK

BASIC MOTOR CONTROL

CONTROL TYPE

Open Vector

STATUS C1601T1 BACK

BASIC MOTOR CONTROL

CONTROL TYPE

V/F Control

STATUS C1601T1 BACK

BASIC MOTOR CONTROL

MOTOR RATED HP

0.5 HP

STATUS F2416T1 BACK

BASIC MOTOR DATA

MOTOR RATED HP

0.5 HP

STATUS C2416T1 BACK

BASIC MOTOR DATA

MOTOR RATED HP

0.5 HP

STATUS C2416T1 BACK

BASIC MOTOR DATA

FEEDBACK SOURCE

Daughter FDBK

STATUS F2409T1 BACK

BASIC MOTOR DATA

CALC MOTOR MODEL

Yes

STATUS F2414 BACK

BASIC MOTOR DATA

CALC MOTOR MODEL

Yes

STATUS F2414 BACK

BASIC MOTOR DATA

ENCODER COUNTS

1024 PPR

STATUS F2408T1 BACK

BASIC MOTOR DATA

CALC MOTOR MODEL

Yes

STATUS F2414 BACK

PROG AUTO TUNE

ONE-STEP TUNING

Yes

BASIC F2902 BACK

PROG AUTO TUNE

ONE-STEP TUNING

Yes

BASIC F2902 BACK

PROG AUTO TUNE

STATOR R1 TUNE

No

BASIC F2903 BACK

MS765 04/12 TCP 5000